At its core, a vibration shaker operates on the same principle as a common audio speaker, but it is engineered for immense power and precision. It functions as an electrodynamic force generator, converting a controlled electrical signal into precise mechanical motion. This process allows engineers and scientists to subject an object, from a microchip to a satellite, to specific and repeatable vibrational forces.

A vibration shaker is not just a motor that shakes; it is a highly sophisticated system that translates electrical energy into precisely controlled physical vibration. Understanding this allows you to see it as a tool for simulating, testing, and manipulating the physical world with extreme accuracy.

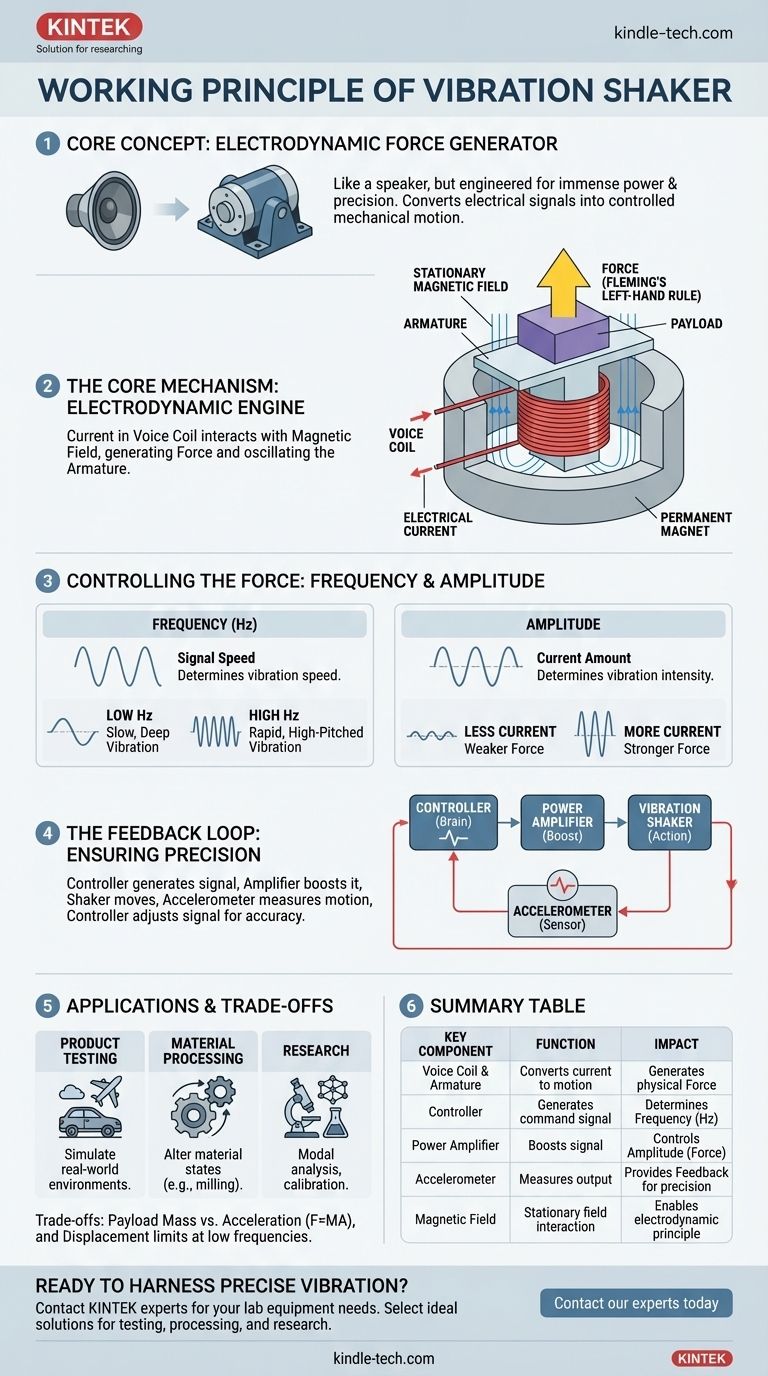

The Core Mechanism: An Electrodynamic Engine

The most common type of vibration shaker, the electrodynamic shaker, is essentially a powerful, linear electric motor. Its operation is governed by a fundamental principle of physics.

The "Voice Coil" and Armature

The heart of the shaker is a cylindrical coil of wire, often called the voice coil, attached to a rigid, lightweight structure known as the armature. The object you want to test (the "payload") is mounted directly to this armature.

Fleming's Left-Hand Rule in Action

This entire armature and coil assembly is suspended within a powerful, stationary magnetic field. When an electrical current is passed through the voice coil, it generates its own magnetic field, which interacts with the stationary field. This interaction produces a physical force, as described by Fleming's Left-Hand Rule, pushing the coil and the attached armature.

From Current to Controlled Motion

By sending an alternating current (AC) through the coil, the direction of the force rapidly reverses, causing the armature to oscillate back and forth. This oscillation is the vibration. The shaker system doesn't just create random movement; it creates highly controlled and predictable motion.

The Role of the Amplifier and Controller

A dedicated power amplifier provides the electrical current to the shaker's voice coil. A separate controller generates the precise electrical waveform that the amplifier boosts. The controller is the brain, telling the shaker exactly how to move.

From Principle to Application: Controlling the Force

The true value of a shaker system lies in its ability to precisely control the two key parameters of vibration: frequency and amplitude. This control is what enables applications like the vibration milling mentioned in your reference.

Why Frequency Matters

The frequency of the vibration, measured in Hertz (Hz), is determined by how quickly the electrical current alternates direction. A low-frequency signal (e.g., 10 Hz) from the controller creates a slow, deep vibration, while a high-frequency signal (e.g., 2,000 Hz) creates a rapid, high-pitched hum. This allows you to simulate anything from the bumpy ride in a truck to the high-frequency vibrations of a jet engine.

How Amplitude is Determined

The amplitude, or intensity of the vibration, is controlled by the amount of current supplied by the amplifier. More current results in a stronger magnetic interaction and thus a larger force, causing the armature to move further or accelerate faster. In an application like vibration milling, this control is critical to apply enough force to break down materials without damaging the equipment.

The Feedback Loop: Ensuring Precision

To guarantee accuracy, a small sensor called an accelerometer is mounted on the armature. This sensor constantly measures the actual vibration being produced and sends a signal back to the controller. The controller compares this real-world feedback to the desired vibration profile and instantly adjusts the electrical signal to correct for any deviation.

Understanding the Trade-offs and Limitations

While powerful, a shaker system's performance is governed by physical and electrical realities. Understanding these trade-offs is key to using one effectively.

Shakers Don't Work in Isolation

A shaker is only one part of a complete test system. It requires a matched power amplifier to drive it and a sophisticated controller to generate the test signals and manage the feedback loop. For high-force shakers, a cooling system (typically air or water) is also essential to dissipate the immense heat generated.

Payload vs. Performance

There is a direct trade-off between the mass of the object you are testing and the maximum acceleration the shaker can achieve. A heavier payload requires more force to accelerate at the same rate. This relationship is governed by Newton's second law: Force = Mass × Acceleration. A shaker has a maximum force rating, so as your mass goes up, your maximum achievable acceleration goes down.

The Limitation of Displacement

The armature has a finite physical travel distance, known as its displacement or stroke limit. This can become a limiting factor at very low frequencies, which naturally require the armature to move a longer distance to produce a given acceleration.

Making the Right Choice for Your Goal

By understanding that a shaker is a tool for precise force generation, you can apply it to your specific objective.

- If your primary focus is product reliability testing: Use the shaker to simulate real-world vibration environments, like road transport or aircraft operation, to identify design weaknesses before they cause failures in the field.

- If your primary focus is material processing: Use the shaker's controlled force and frequency, as in vibration milling, to impart a specific energy into a material to alter its physical state.

- If your primary focus is scientific research or calibration: Use the shaker's precision and repeatability to conduct modal analysis, determine a structure's natural resonant frequencies, or precisely calibrate other vibration sensors.

Ultimately, a vibration shaker gives you the power to recreate and control a fundamental force of the physical world on demand.

Summary Table:

| Key Component | Function | Impact on Vibration |

|---|---|---|

| Voice Coil & Armature | Converts electrical current into linear motion | Generates the physical force (Fleming's Left-Hand Rule) |

| Controller | Generates the command signal (waveform) | Determines the Frequency (Hz) of vibration |

| Power Amplifier | Boosts the signal to drive the shaker | Controls the Amplitude (force/acceleration) |

| Accelerometer | Measures actual vibration output | Provides feedback for precise control and repeatability |

| Magnetic Field | Provides a stationary field for interaction | Enables the electrodynamic force generation principle |

Ready to harness the power of precise vibration for your lab?

Whether your goal is product reliability testing, advanced material processing like vibration milling, or scientific research, having the right equipment is crucial. KINTEK specializes in high-performance lab equipment, including systems that leverage controlled vibration.

Contact our experts today to discuss your specific application. We'll help you select the ideal solution to simulate real-world conditions, process materials efficiently, or achieve breakthrough research results with accuracy and repeatability.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results

- What is the principle of vibratory sieve shaker? Achieve Accurate Particle Size Analysis

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy