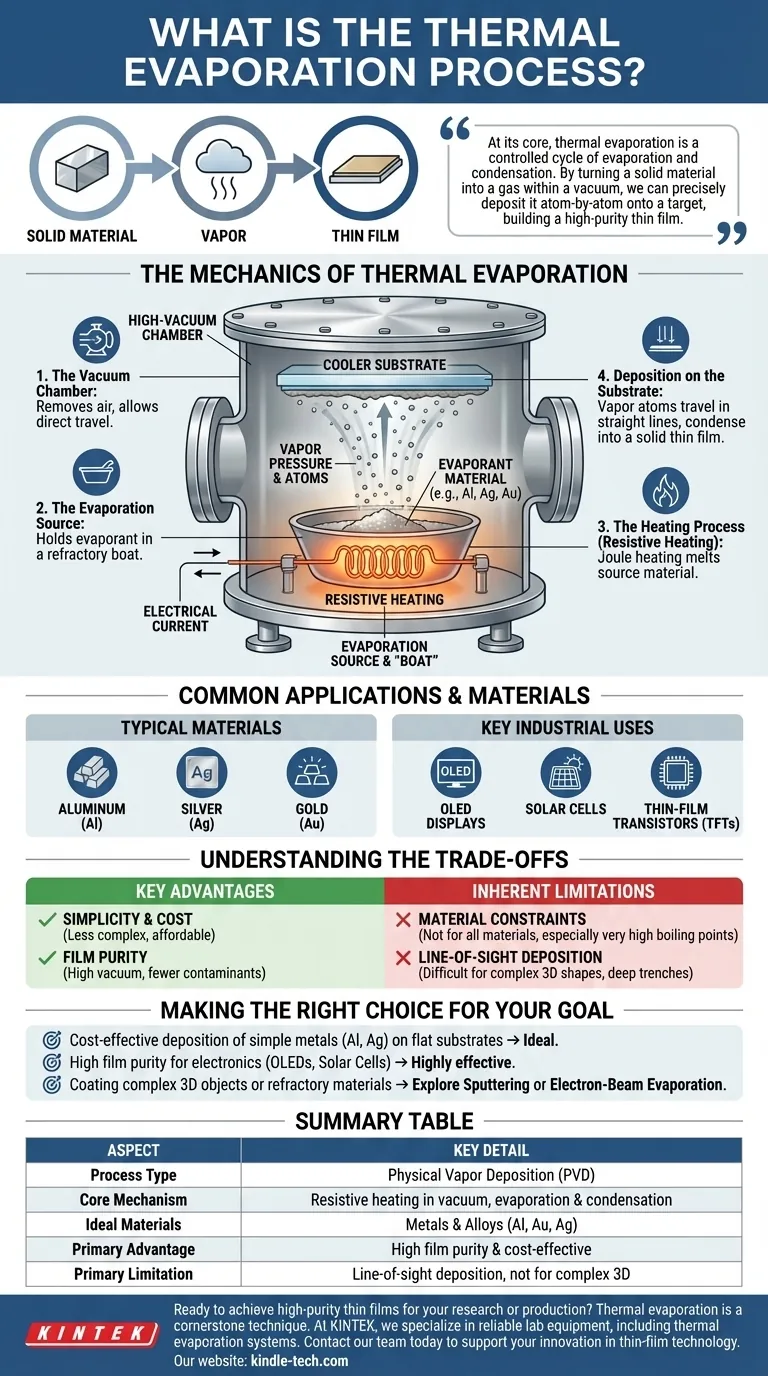

In short, thermal evaporation is a widely used process for creating ultra-thin films by heating a source material in a high vacuum until it turns into a vapor. This vapor then travels and condenses onto a cooler surface, called a substrate, forming a uniform layer. It is a fundamental type of physical vapor deposition (PVD) valued for its relative simplicity and speed.

At its core, thermal evaporation is a controlled cycle of evaporation and condensation. By turning a solid material into a gas within a vacuum, we can precisely deposit it atom-by-atom onto a target, building a high-purity thin film.

The Mechanics of Thermal Evaporation

To understand the process, it's best to break it down into its core components and sequence of events. Each part plays a critical role in the final quality of the deposited film.

The Vacuum Chamber

The entire process takes place inside a high-vacuum chamber, typically made of stainless steel. The vacuum is critical because it removes air and other particles, allowing the evaporated atoms to travel directly to the substrate without colliding with anything else.

The Evaporation Source

The material to be deposited, known as the evaporant, is placed in a small crucible, often called a "boat" or "basket." These boats are made from refractory materials like tungsten or molybdenum, which can withstand extremely high temperatures.

The Heating Process (Resistive Heating)

The most common method is resistive evaporation. A large electrical current is passed through the boat holding the evaporant. Due to its electrical resistance, the boat heats up rapidly—an effect known as Joule heating.

This intense heat first melts the source material and then gives its atoms enough energy to break free and evaporate, creating a vapor pressure within the chamber.

Deposition on the Substrate

The vaporized atoms travel in a straight line through the vacuum until they strike the cooler substrate, which is strategically placed above the source. Upon contact, the atoms lose their energy, condense back into a solid state, and build up layer by layer to form a thin film.

Common Applications and Materials

Thermal evaporation is a workhorse process for depositing specific types of materials, especially in the electronics industry.

Typical Materials

This method is exceptionally well-suited for depositing metals and some alloys that have a reachable evaporation point. Common examples include aluminum (Al), silver (Ag), and gold (Au).

Key Industrial Uses

You will find films created by thermal evaporation in a range of modern technologies. It is a key manufacturing step for OLED displays, solar cells, and thin-film transistors (TFTs), where thin, pure layers of conductive or reflective metals are required.

Understanding the Trade-offs

Like any technical process, thermal evaporation has distinct advantages and limitations that make it suitable for some applications but not others.

Key Advantage: Simplicity and Cost

The equipment for thermal evaporation is generally less complex and more affordable than for other PVD methods. Its operational simplicity and proper speed make it a highly accessible technique for both research and production.

Key Advantage: Film Purity

Because the process occurs in a high vacuum and the source material is heated directly, the resulting films are often very pure. There are fewer opportunities for contaminants to be incorporated into the film compared to more energetic processes.

Inherent Limitation: Material Constraints

Thermal evaporation does not work for all materials. Materials with extremely high boiling points are difficult to heat sufficiently with a resistive boat. Furthermore, some compounds can decompose or break apart when heated, preventing a stable vapor from forming.

Inherent Limitation: Line-of-Sight Deposition

The evaporated atoms travel in straight lines. This means the process is "line-of-sight," making it difficult to uniformly coat substrates with complex, three-dimensional shapes or deep trenches. Areas not in the direct path of the vapor stream will receive little to no coating.

Making the Right Choice for Your Goal

The decision to use thermal evaporation depends entirely on your material, substrate, and the desired film characteristics.

- If your primary focus is cost-effective deposition of simple metals: Thermal evaporation is often the ideal choice for materials like aluminum or silver on flat substrates.

- If your primary focus is high film purity for electronics: This process is highly effective for creating the metallic layers in OLEDs and solar cells where purity is critical.

- If your primary focus is coating complex 3D objects or refractory materials: You should explore alternative PVD methods like sputtering or electron-beam evaporation, which offer better coverage and higher energy.

Ultimately, understanding the fundamental principles of thermal evaporation empowers you to select the right tool for your specific engineering challenge.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Resistive heating of a material in a vacuum, causing evaporation and condensation on a substrate. |

| Ideal Materials | Metals and alloys with reachable evaporation points (e.g., Aluminum, Gold, Silver). |

| Primary Advantage | High film purity and cost-effective operation. |

| Primary Limitation | Line-of-sight deposition, unsuitable for complex 3D shapes. |

Ready to achieve high-purity thin films for your research or production?

Thermal evaporation is a cornerstone technique for depositing critical metal layers in devices like OLED displays and solar cells. At KINTEK, we specialize in providing reliable lab equipment, including thermal evaporation systems, to meet the precise needs of your laboratory.

Our experts can help you select the right tools to ensure efficient, cost-effective, and pure deposition results. Contact our team today to discuss your project requirements and discover how KINTEK can support your innovation in thin-film technology.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Is deposition the same as evaporation? Unraveling the Hierarchy of Thin-Film Technology

- What are the disadvantages of electron beam evaporation? High Cost, Safety Risks & Film Quality Issues

- What is the difference between evaporation and electron beam lithography? Understanding Patterning vs. Deposition

- What are the advantages of sputtering over thermal evaporation? Achieve Superior Thin-Film Quality

- How is film thickness controlled in evaporation? Achieve Nanometer Precision with Quartz Crystal Monitoring

- What are the major differences between thermal evaporation and electron beam evaporation? Choose the Right PVD Method

- What is sputtering or thermal evaporation? Choose the Right Thin-Film Deposition Method

- What is the thermal evaporation technique in a vacuum? A Guide to High-Purity Thin-Film Deposition