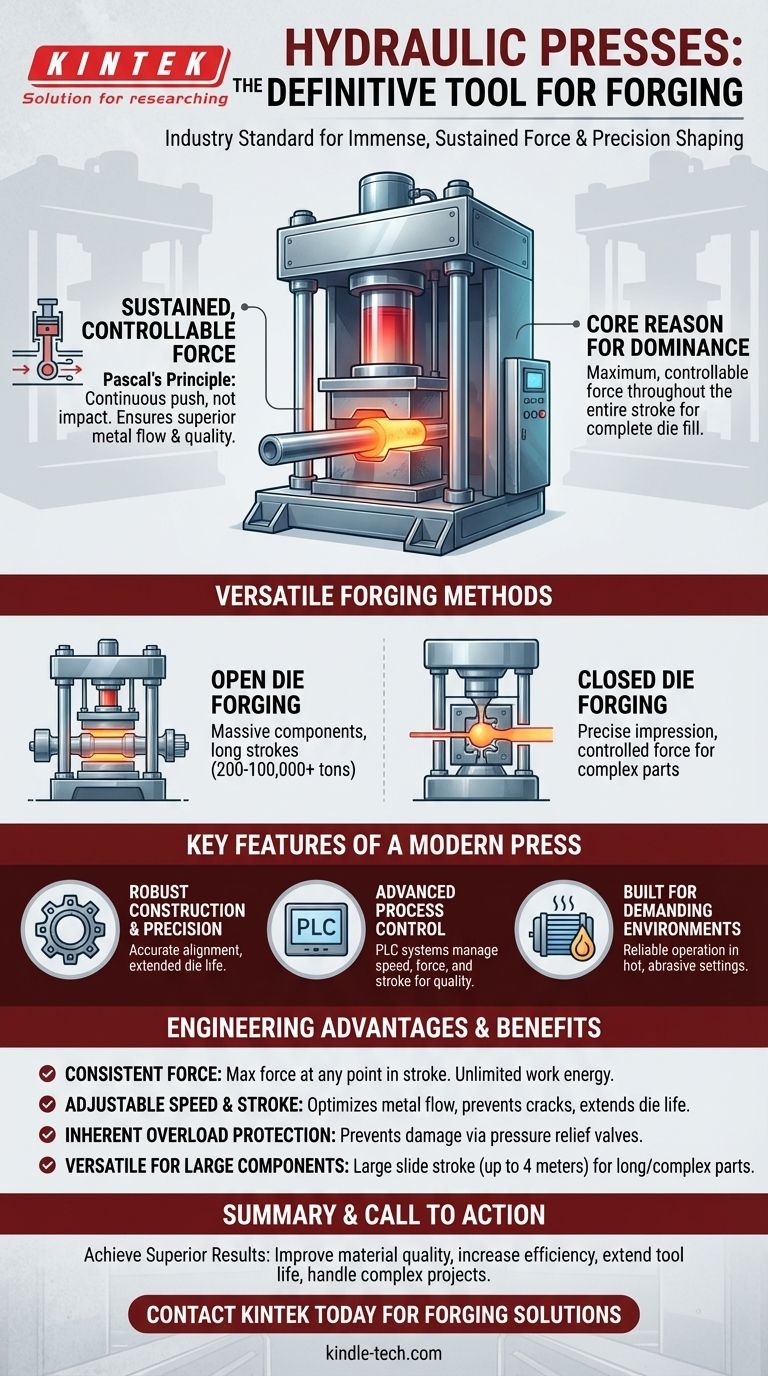

The definitive press used for forging is the hydraulic press. This type of machine is the industry standard for both open die and closed die forging processes, valued for its ability to deliver immense and sustained force. Its design allows it to shape everything from simple components to massive, complex industrial parts with high precision.

The core reason hydraulic presses dominate forging is their unique ability to apply maximum, controllable force throughout the entire pressing stroke. This sustained pressure, unlike the sharp impact of a hammer, allows metal to flow and fill the die completely, resulting in superior workpiece quality and process control.

Why Hydraulic Presses are Essential for Forging

A forging press must perform one primary function: exert enough force to plastically deform a metal workpiece into a desired shape. Hydraulic systems are uniquely suited for this demanding task.

Delivering Sustained, Controllable Force

The power of a hydraulic press comes from Pascal's principle, using pressurized fluid to generate enormous force. This force is not a sudden impact; it is a continuous, controlled push.

This sustained pressure is critical for allowing the metal to flow properly within the die cavity, ensuring the final part is free of defects and possesses a refined grain structure.

Accommodating Different Forging Methods

Hydraulic presses are versatile enough to handle the two main forging processes.

Open die forging involves shaping a workpiece between simple, non-enclosing dies. The immense force and long strokes of large hydraulic presses, ranging from 200 to over 100,000 tons, are ideal for creating massive individual components like industrial shafts.

Closed die forging, also known as impression die forging, squeezes a workpiece between two custom dies that contain a precise impression of the final part. The controlled force of a hydraulic press ensures the metal completely fills the intricate details of the die impression.

Key Features of a Modern Forging Press

Forging presses are not simple machines; they are sophisticated systems designed for precision, durability, and safety in a harsh manufacturing environment.

Immense Force Capacity

The defining feature of a forging press is its power. Capacities for closed die forging commonly reach 60,000 to 82,000 tons, enabling the formation of high-strength alloys and very large parts.

Robust Construction and Precision Guiding

To manage these forces with accuracy, presses are built with highly robust frames. An eight-point slide guide is a common feature that ensures the moving platen remains perfectly aligned, which is critical for producing consistent parts and extending the life of the expensive dies.

Advanced Process Control

Modern presses utilize PLC (Programmable Logic Controller) systems and advanced hydro-electronic controls. This allows operators to precisely manage pressing speed, force, and stroke distance.

This level of control directly translates to higher product quality, better repeatability, and increased production rates.

Features for Demanding Environments

Forging environments are hot and abrasive. Presses are equipped with features like centralized lubrication systems and water-cooled heat exchangers to ensure reliability.

Custom features can also include heated or cooled platens for temperature control, automated die loading systems, and comprehensive safety measures like light curtains and area scanners.

Understanding the Advantages

Choosing a hydraulic press for forging is a decision rooted in several distinct engineering advantages that directly impact product quality and process efficiency.

Consistent Force Through the Entire Stroke

Unlike a mechanical press that delivers peak force only at the bottom of its stroke, a hydraulic press can exert its maximum rated force at any point. This "unlimited work energy" is perfect for long forming operations where the material must be pushed and shaped over a significant distance.

Adjustable Speed and Stroke

The speed of the press slide can be infinitely adjusted. This allows the forming speed to be adapted to the material's properties, preventing cracks and ensuring optimal metal flow. This control leads to superior workpiece quality and significantly longer die service life.

Inherent Overload Protection

A hydraulic system is protected by pressure relief valves. It is impossible to apply more force than the press is designed for, which prevents catastrophic overloading and protects both the machine and the tooling.

Versatility for Large Components

Hydraulic presses can be designed with a very large slide stroke, with working travel distances up to 4 meters. This makes them the only practical choice for forging long or complex components like large fittings or thick-walled pipes.

Applying This to Your Forging Goal

The capabilities of a hydraulic press directly serve the fundamental goals of any forging operation. Understanding this link clarifies its role as the industry's tool of choice.

- If your primary focus is forming extremely large or complex parts: The massive tonnage and long, controllable stroke of a hydraulic press are essential to move the required volume of metal.

- If your primary focus is material quality and strength: The sustained, controlled pressure of a hydraulic system creates a refined grain structure that is impossible to achieve with sudden impacts.

- If your primary focus is process efficiency and tool longevity: The ability to precisely control forming speed and pressure protects expensive dies from premature wear and reduces part rejection rates.

Ultimately, the hydraulic press is the standard for forging because it provides the brute force needed for the task with the sophisticated control required for excellence.

Summary Table:

| Key Feature | Benefit for Forging |

|---|---|

| Sustained, Controllable Force | Ensures complete die fill and superior metal flow |

| Massive Tonnage (up to 100,000+ tons) | Capable of forming large, complex industrial parts |

| Adjustable Speed & Stroke | Protects dies and adapts to material properties |

| Advanced PLC Control | Delivers consistent quality and repeatability |

| Inherent Overload Protection | Safeguards machine and tooling from damage |

Ready to achieve superior forging results with a hydraulic press?

At KINTEK, we specialize in high-performance lab and industrial equipment, including robust forging solutions. Whether you're working on large industrial components or precision parts, our expertise in hydraulic press technology can help you:

- Improve material quality with controlled, sustained pressure

- Increase production efficiency with advanced process control

- Extend tool life through precise speed and force management

- Handle complex projects with massive tonnage capabilities

Let's discuss how a KINTEK hydraulic press can transform your forging operations. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!