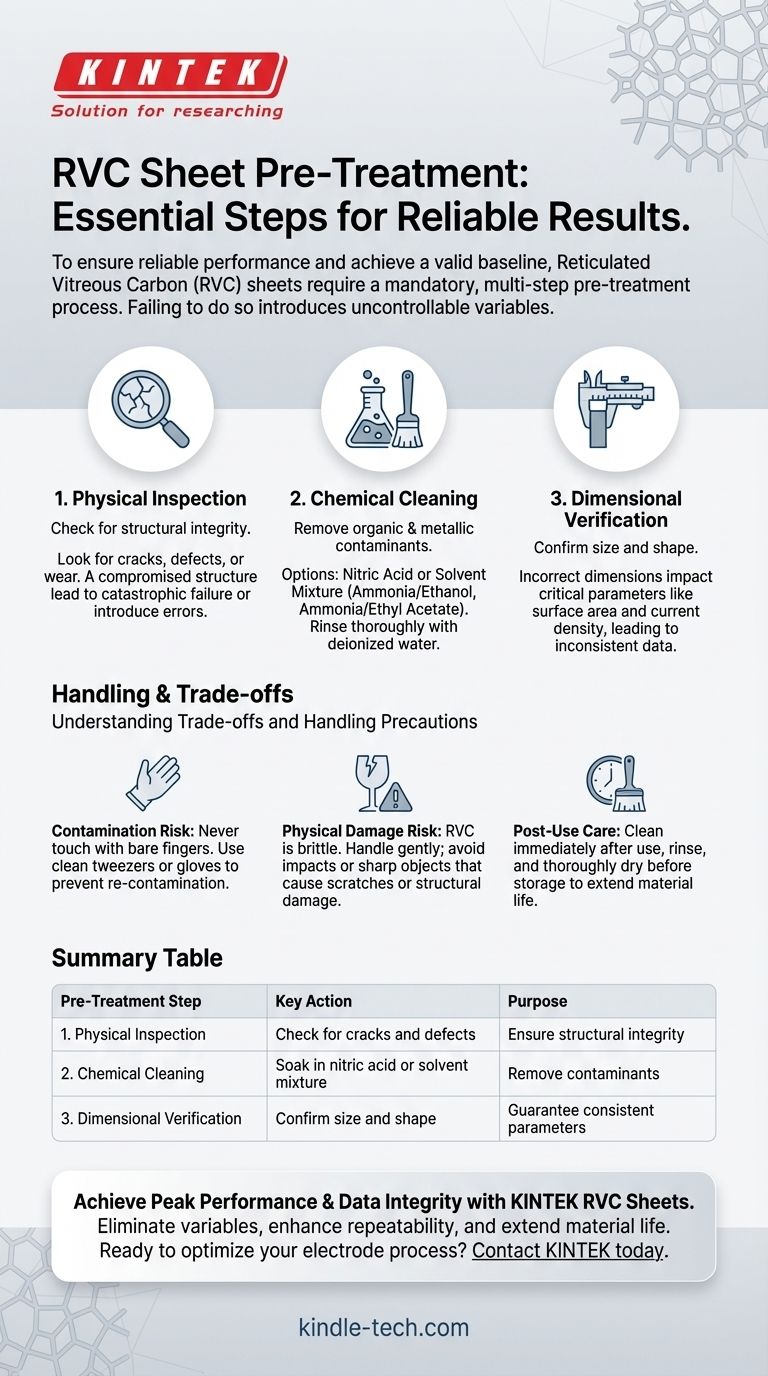

To ensure reliable performance, a Reticulated Vitreous Carbon (RVC) sheet requires a mandatory, multi-step pre-treatment process before use. This involves a thorough physical inspection for damage, an aggressive chemical cleaning to remove surface contaminants, and a final verification of its size and shape for the intended application. These steps are not optional; they are fundamental to achieving accurate and repeatable results.

The core issue is not just cleaning the RVC sheet, but restoring its surface to a known, pristine state. Failing to properly pre-treat the material introduces uncontrollable variables that can invalidate your experimental data and compromise the integrity of your work.

The 'Why' Behind Pre-Treatment: Achieving a Valid Baseline

Each step in the pre-treatment protocol is designed to eliminate a specific variable that could otherwise skew your results. The goal is to ensure the RVC's unique properties are the only thing influencing the outcome.

Step 1: Physical Inspection for Structural Integrity

Before any chemical treatment, perform a close visual inspection of the RVC sheet. Look for any cracks, physical defects, or signs of wear.

A compromised structure can lead to catastrophic failure during an experiment. More subtly, micro-cracks can alter electrical conductivity and surface area, introducing errors that are difficult to diagnose later. If damage is found, the sheet must be replaced.

Step 2: Chemical Cleaning for Surface Purity

The porous, high-surface-area nature of RVC makes it highly susceptible to contamination from organic matter and metallic compounds. These contaminants must be removed to ensure the entire surface is electrochemically active and free from interfering substances.

The standard procedure involves soaking and gently scrubbing the sheet. You have two primary chemical options:

- Nitric Acid: A strong oxidizing agent effective at removing a wide range of contaminants.

- Solvent Mixture: A 1:1 mixture of ammonia water and anhydrous ethanol, or ammonia water and ethyl acetate, can also be used.

After cleaning with any chemical agent, it is critical to rinse the sheet thoroughly with deionized water to remove any residual cleaning agents.

Step 3: Dimensional Verification for Consistency

Finally, confirm that the size and shape of the RVC sheet match the specifications required for your apparatus or experiment.

An incorrect dimension directly impacts critical parameters like total surface area and current density. Using an improperly sized sheet will lead to data that is inconsistent with previous work or theoretical models, making your results difficult to compare or validate.

Understanding the Trade-offs and Handling Precautions

Proper pre-treatment is a balance between being thorough enough to be effective and gentle enough to avoid damaging the material.

Contamination Is a Constant Threat

The primary reason for pre-cleaning is to remove contaminants, so preventing re-contamination is paramount. Never touch the RVC surface with bare fingers, as skin oils are organic contaminants that will compromise your newly cleaned surface. Always use clean tweezers or gloves.

The Risk of Physical Damage

Reticulated Vitreous Carbon is brittle. Handle the sheet gently at all times. Avoid severe impacts or contact with sharp objects that can cause scratches or structural damage. Aggressive scrubbing during the cleaning phase can also fracture the delicate vitreous carbon struts.

The Importance of Post-Use Care

Your pre-treatment for the next experiment begins the moment the current one ends. Clean the RVC sheet immediately after use to remove reactants and byproducts. After a final rinse, ensure it is thoroughly dried—either by air-drying or in a low-temperature oven—before storing it in a clean, dry environment.

Making the Right Choice for Your Goal

Your specific goal dictates which part of the pre-treatment process to emphasize.

- If your primary focus is maximum electrochemical activity: Prioritize the aggressive chemical cleaning step to ensure every possible reaction site is exposed and active.

- If your primary focus is high-precision repeatability: Emphasize consistency in both the cleaning protocol and the dimensional verification to minimize run-to-run variance.

- If your primary focus is long-term material durability: Focus on gentle handling, diligent post-use cleaning, and proper drying and storage to extend the usable life of the RVC sheet.

Ultimately, treating your RVC with this level of discipline transforms it from a simple component into a reliable instrument for discovery.

Summary Table:

| Pre-Treatment Step | Key Action | Purpose |

|---|---|---|

| 1. Physical Inspection | Check for cracks and defects | Ensure structural integrity and prevent failure |

| 2. Chemical Cleaning | Soak in nitric acid or solvent mixture | Remove organic and metallic contaminants |

| 3. Dimensional Verification | Confirm size and shape | Guarantee consistent surface area and current density |

Achieve Peak Performance and Data Integrity with KINTEK RVC Sheets

Proper pre-treatment is the foundation of reliable electrochemical experiments. KINTEK specializes in providing high-quality Reticulated Vitreous Carbon (RVC) sheets and the expert guidance needed to maximize their performance and lifespan in your laboratory.

We help you:

- Eliminate Variables: Ensure your RVC surface is in a pristine, known state for valid baselines.

- Enhance Repeatability: Achieve consistent, accurate results experiment after experiment.

- Extend Material Life: Implement best practices for handling, cleaning, and storage.

Ready to optimize your RVC electrode process? Let our experts provide the materials and support you need for discovery.

Contact KINTEK today for a consultation to discuss your specific lab equipment and consumable needs!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Graphite Vacuum Continuous Graphitization Furnace

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are the material properties of carbon paper? Unlocking High Conductivity & Porosity for Your Lab