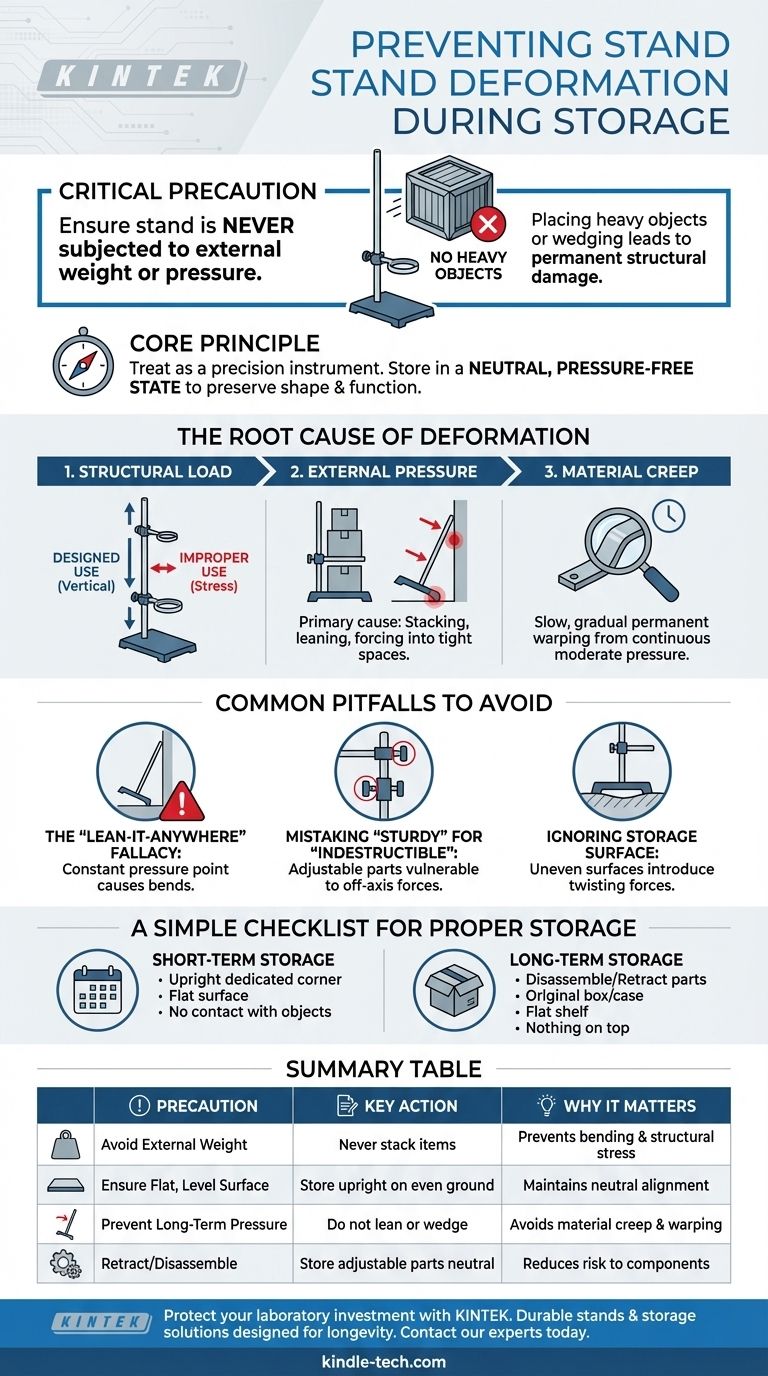

The most critical precaution is to ensure the stand is never subjected to external weight or pressure while in storage. Placing heavy objects on top of it or wedging it into a tight space can cause the materials to bend, leading to permanent structural damage.

The core principle is to treat the stand as a precision instrument, not just a piece of hardware. Its structural integrity depends on storing it in a neutral, pressure-free state, preserving its intended shape and function for future use.

The Root Cause of Stand Deformation

To properly protect your equipment, it's essential to understand why deformation happens. The issue isn't just about avoiding obvious damage; it's about preventing the slow, cumulative effects of improper storage.

Understanding Structural Load

Stands are engineered to support weight and stress in a very specific, vertical orientation. The materials and design are optimized for this intended use.

When stored improperly, the stand is subjected to forces it was not designed to handle, leading to stress on its components.

The Dangers of External Pressure

External pressure is any force applied to the stand while it's not in its operational state. This is the primary cause of deformation.

This includes stacking other equipment on top of it, leaning heavy items against it, or forcing it into a space that is too small.

The Concept of Material Creep

Even a moderate amount of pressure, if applied continuously over a long period, can cause material creep.

This is a slow, gradual bending or warping of the material at a molecular level. Once it occurs, the deformation is often permanent and can compromise the stand's stability.

Common Pitfalls to Avoid

Many stands are damaged due to simple, avoidable mistakes that seem harmless at first glance. Being aware of these common pitfalls is key to long-term preservation.

The "Lean-It-Anywhere" Fallacy

Leaning a stand against a wall might seem convenient, but it creates a constant pressure point. Over weeks or months, this can easily cause a slight but permanent bend in the support columns.

Mistaking "Sturdy" for "Indestructible"

While a stand may feel robust and durable during normal use, its components are not designed to resist prolonged, off-axis forces. This is especially true for adjustable or telescoping parts, which can be easily damaged.

Ignoring the Storage Surface

Placing the stand on an uneven surface can also introduce subtle twisting forces. Always ensure it rests on a flat, level floor to maintain its neutral alignment.

A Simple Checklist for Proper Storage

Use these guidelines to ensure your stand remains in perfect condition, whether you're storing it for a day or a year.

- If your primary focus is short-term storage: Find a dedicated corner where the stand can be placed upright on a flat surface, free from any contact with other objects.

- If your primary focus is long-term storage: Disassemble the stand if possible or retract all adjustable parts, and store it in its original box or a dedicated case on a flat shelf, ensuring nothing is placed on top of it.

Ultimately, protecting your stand during storage is about preventing unnecessary stress on its components.

Summary Table:

| Precaution | Key Action | Why It Matters |

|---|---|---|

| Avoid External Weight | Never stack items on the stand | Prevents bending and structural stress |

| Ensure Flat, Level Surface | Store upright on even ground | Maintains neutral alignment and prevents twisting |

| Prevent Long-Term Pressure | Do not lean against walls or wedge in tight spaces | Avoids material creep and permanent warping |

| Retract/Disassemble if Possible | Store adjustable parts in neutral position | Reduces risk of damage to telescoping components |

Protect your laboratory investment with KINTEK. Proper storage is just one part of preserving your equipment's accuracy and lifespan. As your trusted partner in lab equipment and consumables, KINTEK provides durable stands and storage solutions designed for longevity and precision. Don't let improper storage compromise your results—contact our experts today to find the right equipment and care strategies for your laboratory needs.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- Why is a heated hydraulic press used for warm pressing NASICON green tapes? Optimize Your Solid Electrolyte Density

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the function of a laboratory hydraulic hot press in the assembly of solid-state photoelectrochemical cells?