When connecting a platinum disk electrode, the immediate precautions are to ensure the connections are correct to prevent short circuits and to observe the correct polarity to avoid reversing the positive and negative terminals. These electrical safety steps are foundational, protecting both your instrumentation and the electrode itself from immediate damage.

The core principle extends beyond just the initial connection. Protecting a platinum disk electrode requires a holistic approach that safeguards its physical integrity, chemical purity, and operational environment to ensure both its longevity and the accuracy of your electrochemical measurements.

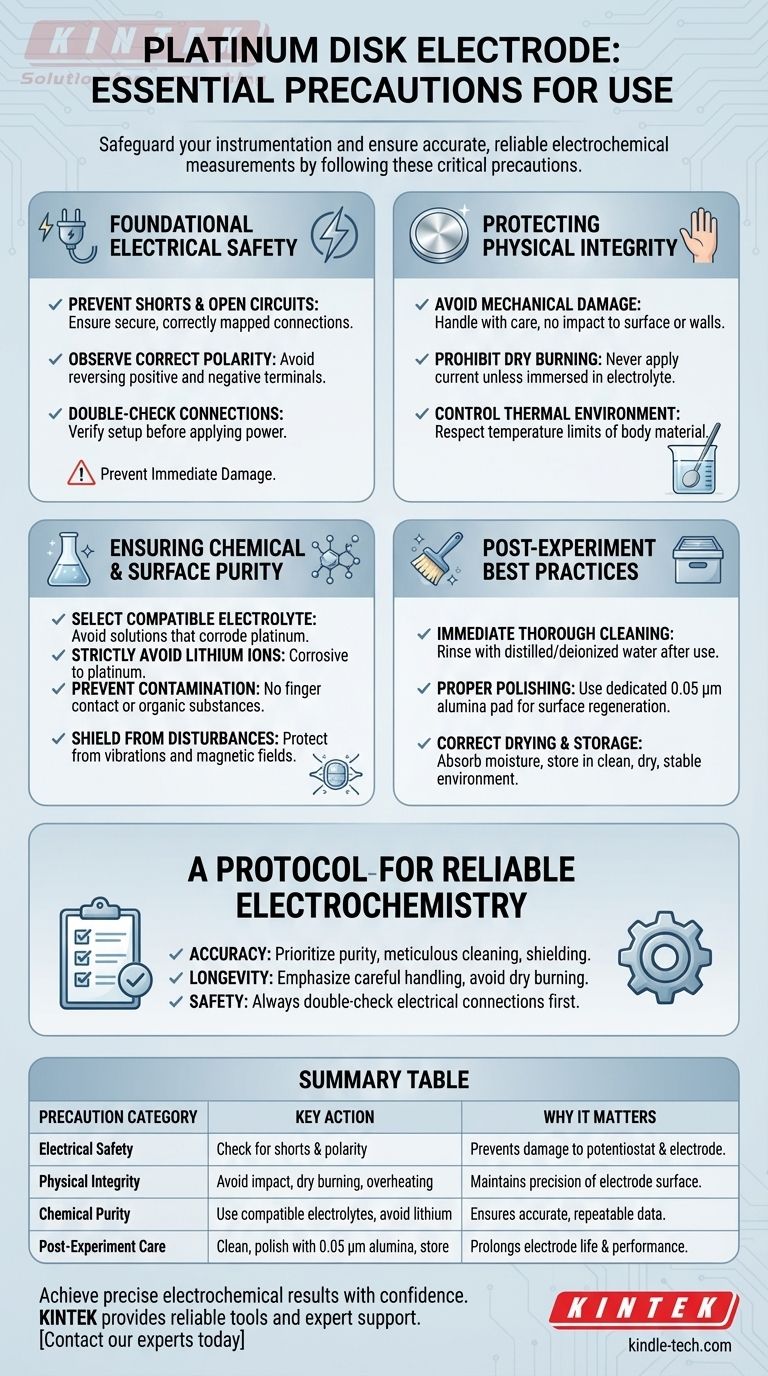

Foundational Electrical Safety

The first step in any experiment is ensuring the electrical setup is correct. Errors here can be costly, damaging sensitive potentiostats and the electrode itself.

Preventing Shorts and Open Circuits

A short circuit can draw excessive current, while an open circuit prevents any measurement from occurring. Double-check that all connections are secure and correctly mapped to the instrument's working, reference, and counter electrode terminals.

Observing Correct Polarity

Reversing the positive and negative connections can lead to unintended and potentially damaging electrochemical reactions. Always confirm the polarity of the connections before applying any potential or current.

Protecting the Electrode's Physical Integrity

A platinum disk electrode is a precision instrument. Its physical condition is directly linked to its performance, and it is more fragile than it may appear.

Avoid All Mechanical Damage

The platinum surface is soft and easily scratched, deformed, or damaged by impact. Handle the electrode with care, and never let it collide with the walls of the cell or other hard surfaces.

Prohibit Dry Burning

Never apply a current or potential to the electrode when it is not fully immersed in an electrolyte. This practice, known as dry burning, can cause irreversible damage to the electrode surface and its housing.

Control the Thermal Environment

If conducting experiments at high temperatures, ensure you do not exceed the specified heat resistance of the electrode's body material (e.g., PEEK or glass). Overheating can cause permanent damage.

Ensuring Chemical and Surface Purity

The quality of your data depends entirely on the condition of the electrode's surface. Contamination and corrosion are the primary threats to accurate and repeatable measurements.

Select a Compatible Electrolyte

The choice of electrolyte is critical. You must select a solution that does not corrode platinum. Crucially, avoid any contact with lithium ions, which are known to be corrosive to platinum and are strictly prohibited for use with these electrodes.

Prevent Surface Contamination

The electrode surface must be pristine. Avoid touching it with your fingers and prevent its contact with organic substances or other materials that could foul it. When polishing, always use a dedicated pad for each type of polishing powder to avoid cross-contamination.

Shield from External Disturbances

For sensitive measurements, the experimental environment must be stable. Shield the setup from mechanical vibrations and external magnetic fields, as these can introduce noise and interfere with results.

Understanding Post-Experiment Best Practices

How you handle the electrode after an experiment is just as important as how you handle it during. Proper cleaning and storage are non-negotiable for long-term performance.

Immediate and Thorough Cleaning

As soon as an experiment concludes, remove the electrode from the electrolyte. Rinse it thoroughly with distilled or deionized water to remove any residual solution.

Proper Polishing Technique

For stubborn residue or to regenerate the surface, you can polish it. Use a fine abrasive like 0.05 µm alumina powder on a dedicated polishing pad.

Correct Drying and Storage

After rinsing, gently absorb moisture with filter paper. Store the clean, dry electrode in a dedicated container, away from humid environments, high temperatures, and strong light.

A Protocol for Reliable Electrochemistry

Your approach to using the electrode should be guided by your primary experimental goal.

- If your primary focus is data accuracy and repeatability: Prioritize surface purity by using meticulous cleaning protocols, preventing contamination, and shielding the setup from environmental noise.

- If your primary focus is electrode longevity: Emphasize careful physical handling, avoiding dry burning at all costs, and implementing a strict post-experiment cleaning and storage routine.

- If your primary focus is instrument safety: Always begin by double-checking your electrical connections for correct terminal assignment and polarity before powering on your equipment.

Ultimately, treating your platinum disk electrode as the precision scientific instrument it is will ensure it delivers reliable data for years to come.

Summary Table:

| Precaution Category | Key Action | Why It Matters |

|---|---|---|

| Electrical Safety | Check for shorts & correct polarity. | Prevents damage to potentiostat and electrode. |

| Physical Integrity | Avoid impact, dry burning, and overheating. | Maintains the precision of the electrode surface. |

| Chemical Purity | Use compatible electrolytes; avoid lithium ions. | Ensures accurate, repeatable electrochemical data. |

| Post-Experiment Care | Clean, polish with 0.05 µm alumina, and store properly. | Prolongs electrode life and performance. |

Achieve precise and reliable electrochemical results with confidence. Properly maintaining your platinum disk electrode is critical for data integrity. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools and expert support your laboratory needs. Contact our experts today to discuss your specific requirements and ensure your electrochemical setup is optimized for success.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance