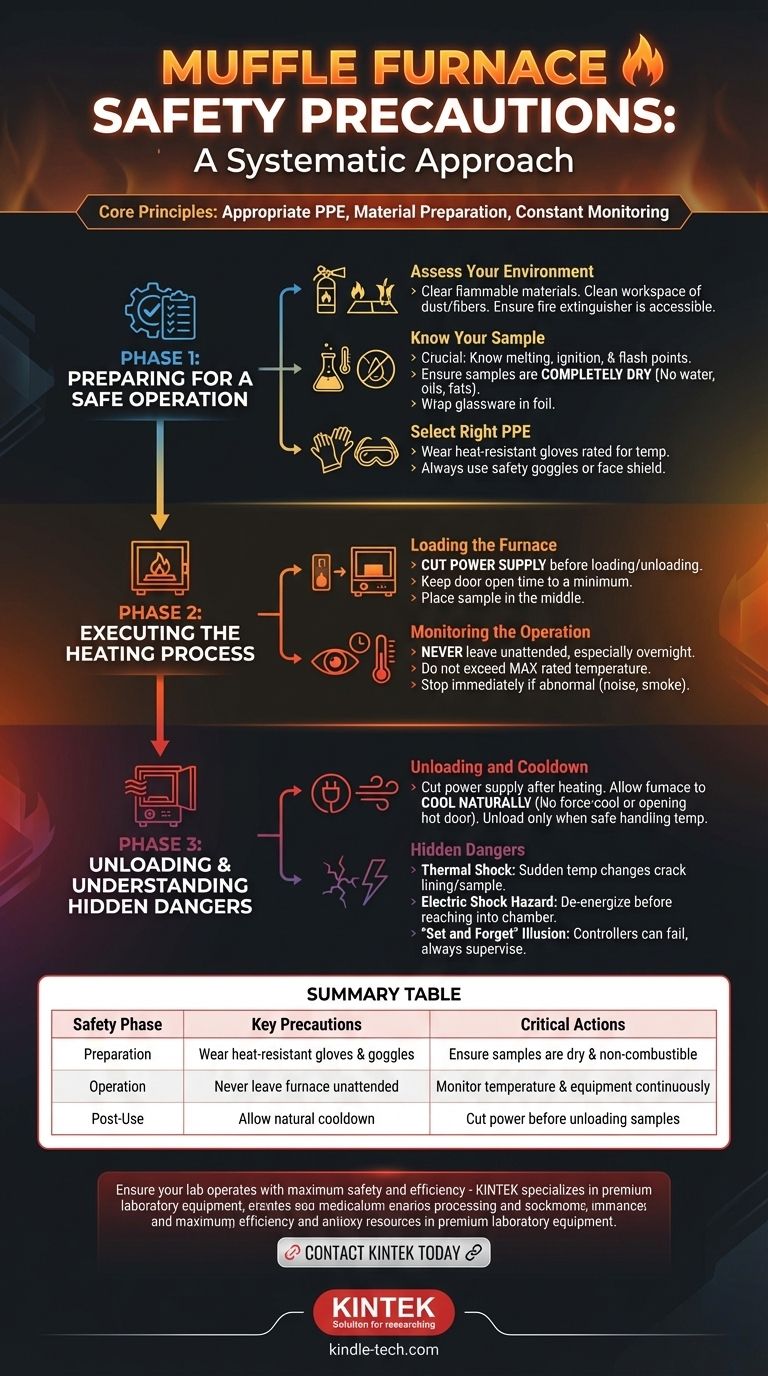

Operating a muffle furnace demands a systematic approach to safety centered on three core principles: wearing appropriate personal protective equipment (PPE), meticulously preparing your materials, and constantly monitoring the equipment during operation. Due to the extreme temperatures involved, you must always use heat-resistant gloves and safety goggles, ensure any sample is dry and non-combustible, and never leave the furnace unattended while it is heating.

A muffle furnace is an incredibly powerful tool, but its high temperatures create an unforgiving environment. True safety is not about a single action, but a disciplined, multi-layered process that encompasses personal protection, material awareness, and strict adherence to operational procedures before, during, and after every use.

Phase 1: Preparing for a Safe Operation

Before you ever turn the power on, you must prepare yourself, your sample, and your workspace. This foundational step prevents the most common and dangerous incidents.

Assess Your Environment

Your immediate surroundings are your first line of defense. The area must be clear, clean, and equipped for emergencies.

Keep the furnace area completely clear of flammable materials. The furnace jacket itself becomes extremely hot and can ignite nearby objects.

Ensure the workspace is clean and free of ambient dust or fibers, which can be drawn into the furnace and contaminate your sample or the equipment.

Always confirm a suitable fire extinguisher is nearby and that you know how to use it. Familiarize yourself with your facility's emergency procedures.

Know Your Sample

What you put inside the furnace is the single greatest variable. Understanding its properties is not optional; it is essential for preventing fires, explosions, and equipment damage.

Crucially, you must know the melting, ignition, or flash combustion points of all materials being heated.

Ensure all samples are completely dry. Never place samples containing water, oils, fats, or other liquids into the chamber. Rapidly expanding vapor can cause damage, and volatile substances can release corrosive gases or ignite.

Materials containing fats can release corrosive gases when heated, which will attack and destroy the furnace's heating elements over time, shortening its lifespan.

For glassware, cover the open ends of Pyrex with aluminum foil. For very small items, it's good practice to wrap them in foil to prevent loss or contamination.

Select the Right Personal Protective Equipment (PPE)

The extreme heat generated by a muffle furnace requires specialized protection. Standard lab gear is not sufficient.

Always wear heat-resistant gloves when loading or unloading the furnace. The type of glove must be rated for the temperatures you are working with.

Wear safety goggles or a face shield at all times when operating the furnace to protect your eyes from intense heat and potential projectiles.

Phase 2: Executing the Heating Process

Safe operation is a structured process. Following these steps consistently minimizes risk during the most hazardous phases of furnace use.

Loading the Furnace

To prevent electric shock and thermal damage, loading must be done deliberately.

Cut the power supply before loading or unloading samples. This eliminates the risk of electric shock from contact with the heating elements.

Keep the time the furnace door is open to a minimum. This maintains thermal stability inside the chamber and reduces your exposure to heat.

Place your sample in the middle of the furnace chamber and ensure it is positioned neatly and securely.

Monitoring the Operation

A muffle furnace should never be a "set and forget" device. Active monitoring is critical to prevent accidents from control failures.

Never leave the furnace unattended while it is running, especially overnight. If a controller fails, temperatures can rise uncontrollably and create a serious fire hazard.

Do not exceed the maximum rated temperature of the furnace. Pushing the equipment beyond its design limits can cause catastrophic failure.

If you notice any abnormalities—such as strange noises, smoke, or a temperature display that doesn't match the setpoint—stop the operation immediately, turn off the power, and contact maintenance personnel.

Unloading and Cooldown

The process is not over until the furnace and its contents are safely back at room temperature.

After the heating cycle is complete, cut the power supply.

Allow the furnace to cool down naturally. Do not force-cool it or open the door while it is still at a high temperature. This prevents thermal shock to the furnace lining and your sample, and protects you from a blast of superheated air.

Only open the door and remove your sample once the furnace has cooled to a safe handling temperature.

Understanding the Hidden Dangers

Beyond the obvious risk of burns, several less apparent hazards can lead to equipment failure or injury. Understanding these is the mark of a true professional.

The Risk of Thermal Shock

Sudden, drastic changes in temperature can crack the furnace's refractory lining or shatter your sample. This is why you must let the furnace cool naturally before opening the door and avoid putting cold items into a very hot furnace. Similarly, never suddenly pull out a thermocouple at high temperatures, as this can damage the sensor and furnace jacket.

The Electric Shock Hazard

A muffle furnace is a high-power electrical appliance. The heating elements carry a dangerous voltage. Always de-energize the unit by cutting the main power before reaching into the chamber for any reason.

The Illusion of "Set and Forget"

Modern digital controllers provide excellent precision, but they can fail. Relying on them completely without human supervision is a significant gamble. The only way to prevent an accident from a control failure is to be present to intervene.

A Safety Checklist for Your Workflow

Integrate these key checks into your process to ensure a safe and successful outcome every time.

- If your primary focus is routine ashing or heat treatment: Double-check that all samples are completely dry and free of oils to protect the furnace's heating elements and ensure accurate results.

- If you are working with novel or unfamiliar materials: Always research the material's decomposition behavior and flash point before placing it in the furnace to prevent unexpected reactions.

- If you are responsible for lab management: Ensure all operators are formally trained and that fire extinguishers and emergency protocols are clearly visible and regularly reviewed.

By treating the muffle furnace with disciplined respect, you ensure both your personal safety and the integrity of your work.

Summary Table:

| Safety Phase | Key Precautions | Critical Actions |

|---|---|---|

| Preparation | Wear heat-resistant gloves and safety goggles | Ensure samples are dry and non-combustible |

| Operation | Never leave furnace unattended | Monitor temperature and equipment continuously |

| Post-Use | Allow natural cooldown | Cut power before unloading samples |

Ensure your lab operates with maximum safety and efficiency - KINTEK specializes in premium laboratory equipment and consumables designed with safety as the top priority. Our muffle furnaces feature advanced safety controls and durable construction to protect your team and your research.

Let our experts help you select the right equipment for your specific high-temperature applications. Contact KINTEK today to discuss your laboratory needs and discover how our solutions can enhance your workflow safety and productivity.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the importance of a muffle? Achieve Purity and Precision in High-Temperature Processes

- What is the critical point of heat treatment? Master the Key to Steel Transformation

- What is the heat transfer of a muffle furnace? Understanding Indirect Heating for Purity

- What is the working principle of muffle furnace? Achieving Pure, Uniform High-Temperature Processing

- What is the difference between electric oven and muffle furnace? Choose the Right High-Temp Lab Equipment