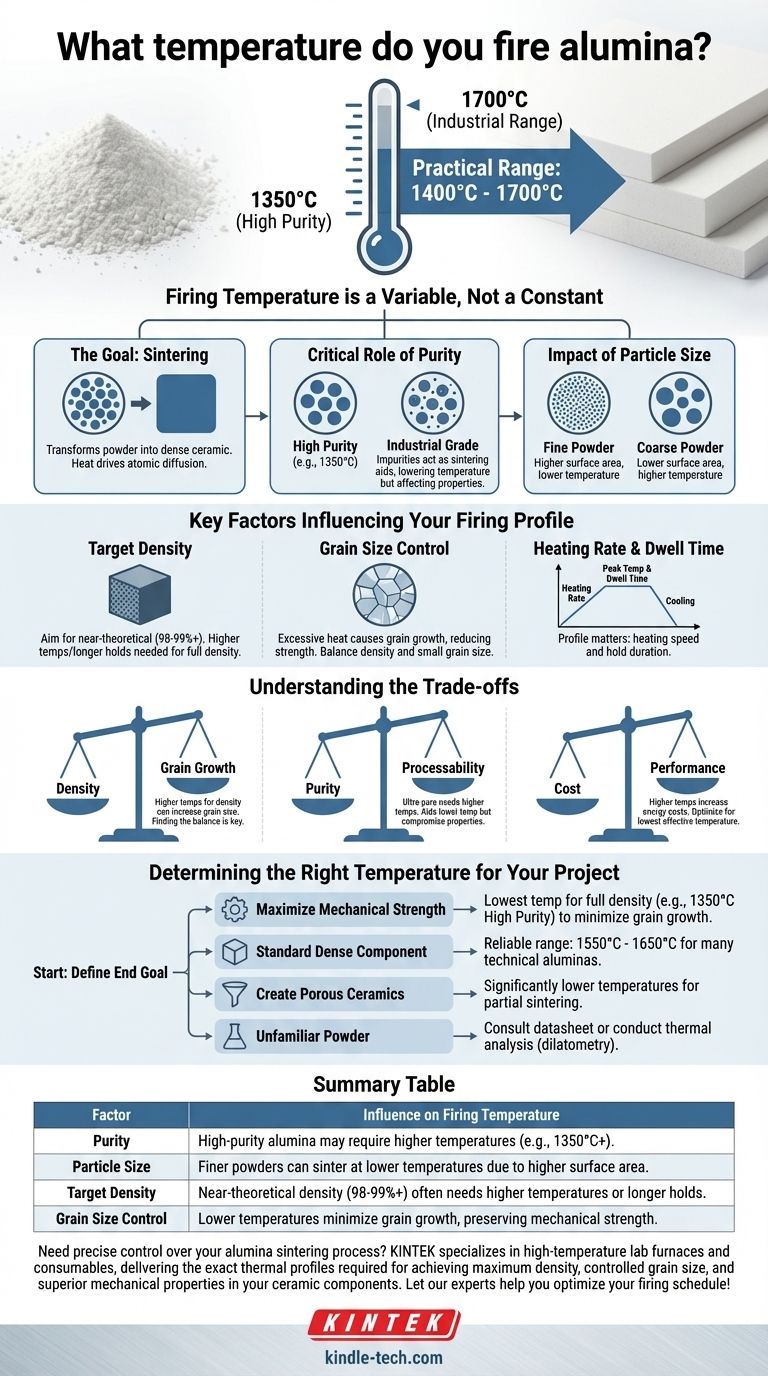

The firing temperature for alumina is not a single value but a critical process variable that depends on your material and goals. While specific research on high-purity alumina powders has achieved 99% density by firing at 1350°C for just 20 minutes, the practical range for most industrial and technical applications is typically much higher, often between 1400°C and 1700°C.

The ideal firing temperature for alumina is a function of your starting material and desired final properties. It is not a fixed number but a critical parameter you must control to achieve specific outcomes like maximum density, controlled grain size, or high strength.

Why Firing Temperature is a Variable, Not a Constant

The process of firing, known as sintering, is what transforms a compacted powder into a solid, dense ceramic component. Temperature is the primary driver of the atomic diffusion that bonds these particles together. The specific temperature required is dictated by several interconnected factors.

The Goal of Firing (Sintering)

Sintering aims to reduce the porosity between the initial powder particles, causing the component to shrink and densify. Heat provides the energy for atoms to move across particle boundaries, effectively welding them into a cohesive mass with a crystalline structure.

The Critical Role of Purity

The 1350°C example applies to a high-purity alumina. Industrial-grade aluminas often contain small amounts of other oxides (like silica or magnesia) which can act as sintering aids. These additives can lower the temperature required to achieve full density, but may affect the final chemical or electrical properties.

Impact of Starting Particle Size

The initial size of the alumina powder particles has a profound effect on the sintering process. Finer powders have a much higher surface area, which provides a greater driving force for densification. This allows them to be sintered at lower temperatures or for shorter times, as seen in the research example.

Key Factors Influencing Your Firing Profile

Simply choosing a peak temperature is not enough. You must consider the entire heating profile and the final properties you need to achieve.

Target Density

The primary goal of most sintering operations is to achieve near-theoretical density, eliminating porosity which can act as a failure point. Reaching that final 98-99%+ density range often requires higher temperatures or longer hold times to remove the last remaining pores.

Grain Size Control

As alumina is held at high temperatures, its microscopic crystal grains will grow larger. While densification is good, excessive grain growth can be detrimental to mechanical properties like hardness and fracture toughness. The research result of a 1.2 μm grain size at 1350°C is an excellent outcome, indicating high density was achieved without allowing grains to grow too large.

Heating Rate and Dwell Time

The firing profile consists of more than just a peak temperature. It includes the heating rate (how fast you raise the temperature) and the dwell time (how long you hold it at the peak temperature). The 20-minute dwell time in the reference is quite short, enabled by the reactive, high-purity powder. Slower heating rates and longer dwell times are often necessary for larger parts or less-reactive powders.

Understanding the Trade-offs

Optimizing a firing process always involves balancing competing factors. Understanding these trade-offs is essential for producing a reliable component.

Density vs. Grain Growth

This is the classic sintering dilemma. The conditions that promote the final stages of densification—high temperatures and long times—are the same ones that cause unwanted grain growth. A successful firing schedule achieves maximum density while keeping the grain size as small as possible.

Purity vs. Processability

Using an ultra-pure alumina may offer superior performance, but it often requires higher sintering temperatures. Adding sintering aids can lower energy costs and make processing easier, but it comes at the cost of compromising the material's intrinsic properties.

Cost vs. Performance

Higher firing temperatures directly translate to higher energy costs and require more advanced, expensive furnace equipment. Optimizing your powder and firing profile to use the lowest effective temperature is a critical economic consideration in any production environment.

Determining the Right Temperature for Your Project

Use your end goal to guide your decision-making process for selecting a firing temperature and profile.

- If your primary focus is maximizing mechanical strength: Aim for the lowest possible temperature that achieves full density to minimize grain growth, mirroring the 1350°C research example.

- If your primary focus is producing a standard, dense component: A temperature range of 1550°C to 1650°C is a common and reliable starting point for many technical-grade aluminas.

- If your primary focus is creating porous ceramics (e.g., for filters): You will use significantly lower temperatures to only partially sinter the particles, intentionally leaving porosity in the structure.

- If you are working with an unfamiliar powder: Always begin with the manufacturer's technical datasheet or conduct your own thermal analysis (dilatometry) to determine the material's specific sintering behavior.

Ultimately, treating the firing temperature as a precise tool to control the final material properties is the key to successful ceramic engineering.

Summary Table:

| Factor | Influence on Firing Temperature |

|---|---|

| Purity | High-purity alumina may require higher temperatures (e.g., 1350°C+). |

| Particle Size | Finer powders can sinter at lower temperatures due to higher surface area. |

| Target Density | Near-theoretical density (98-99%+) often needs higher temperatures or longer holds. |

| Grain Size Control | Lower temperatures minimize grain growth, preserving mechanical strength. |

Need precise control over your alumina sintering process? KINTEK specializes in high-temperature lab furnaces and consumables, delivering the exact thermal profiles required for achieving maximum density, controlled grain size, and superior mechanical properties in your ceramic components. Let our experts help you optimize your firing schedule—contact us today to discuss your specific alumina application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you clean a muffle furnace? A Step-by-Step Guide to Ensure Safety and Longevity

- What is the temperature verification of muffle furnace? Ensure Accurate Thermal Processing

- What is the main function of the muffle furnace? Achieve Pure, High-Temperature Heating Without Contamination

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- What are the risks of using a muffle furnace? Mitigate Thermal, Material, and Operational Hazards