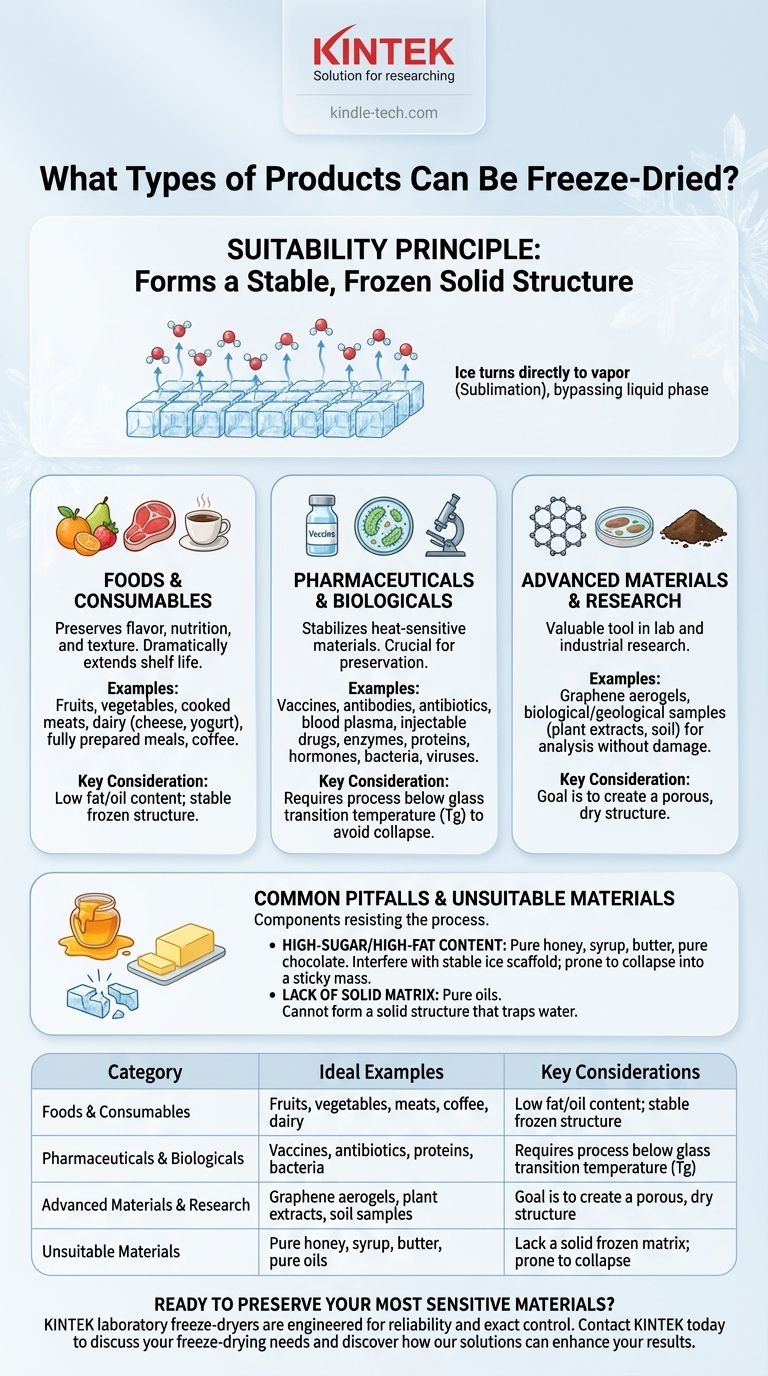

In principle, an incredibly wide range of products can be freeze-dried. The process is suitable for most foods, sensitive pharmaceuticals, and various biological materials. Key categories include fruits, vegetables, meats, coffee, vaccines, antibiotics, bacteria cultures, and even advanced materials like graphene.

The suitability of a product for freeze-drying hinges on a single core principle: its ability to form a stable, frozen solid structure from which water can be removed. This is why products with high water content and a solid matrix are ideal, while those high in oils, fats, or certain sugars present significant challenges.

The Primary Categories of Suitable Products

Freeze-drying, or lyophilization, is a versatile process applied across many industries. Its effectiveness depends on the product's chemical and physical structure.

Foods and Consumables

This is the most well-known application, valued for preserving flavor, nutrition, and texture while dramatically extending shelf life.

Ideal candidates include fruits, vegetables, cooked meats, dairy products like cheese and yogurt, and even fully prepared meals. Coffee is another common example, where freeze-drying preserves the aromatic compounds better than other drying methods.

Pharmaceuticals and Biologicals

This is arguably the most critical application, as it allows for the stabilization of heat-sensitive and delicate materials.

The process is essential for preserving vaccines, antibodies, antibiotics, blood plasma, and injectable drugs. It is also used for stabilizing enzymes, proteins, hormones, bacteria, and viruses for research, diagnostics, and probiotics.

Advanced Materials and Research

Freeze-drying is also a valuable tool in laboratory and industrial research settings.

It can be used to prepare highly porous materials like graphene aerogels. Scientists also use it to dry biological or geological samples, such as plant extracts or soil (earth), for analysis without damaging their delicate structures.

The Defining Principle: Why It Works (or Doesn't)

To understand what can be freeze-dried, you must understand the underlying mechanism of sublimation—turning ice directly into vapor.

The Critical Role of Water and Structure

Freeze-drying works by first freezing a product solid, then creating a vacuum and gently adding heat. This allows the frozen water to sublimate, bypassing the liquid phase entirely.

For this to succeed, the product must have a rigid, solid structure when frozen. This structure acts as a scaffold, holding its shape after the ice has been removed, resulting in a lightweight, porous final product.

Amorphous vs. Crystalline Structures

Many complex biologicals and pharmaceuticals do not form a simple ice crystal structure. Instead, they become amorphous solids, which are more like a rigid, glass-like state.

For these materials, the process must be performed below a critical temperature known as the glass transition temperature (Tg). If the temperature rises above this point during drying, the "glass" will soften and collapse, ruining the product.

Common Pitfalls and Unsuitable Materials

While versatile, freeze-drying is not a universal solution. Certain components actively resist the process.

The Challenge of High-Sugar and High-Fat Content

Products with very high concentrations of pure sugar, oil, or fat are not suitable for freeze-drying.

Examples include pure honey, syrup, butter, and pure chocolate. These substances interfere with the formation of a stable, rigid ice scaffold. They often have very low glass transition temperatures, making them prone to collapse into a sticky, useless mass instead of drying properly.

The Requirement of a Solid Matrix

The product must be able to form a solid matrix upon freezing. Pure oils or other substances that do not solidify in a way that traps water cannot be freeze-dried.

The process is fundamentally about removing water from a solid structure. If that structure doesn't exist, the process fails.

Making the Right Choice for Your Application

Selecting the right products for freeze-drying requires understanding your primary goal and the material's composition.

- If your primary focus is food preservation: Choose items with low fat and structural integrity, such as fruits, vegetables, and lean meats, for the best texture and rehydration results.

- If your primary focus is pharmaceutical or biological stability: You must characterize the product's glass transition temperature to ensure you can maintain the cold, high-vacuum conditions needed to protect delicate molecules.

- If your primary focus is material science: Select materials where creating a porous, lightweight structure from a water-based slurry or sample is the desired outcome.

Ultimately, successful freeze-drying depends less on the product category and more on its fundamental physical structure when frozen.

Summary Table:

| Category | Ideal Examples | Key Considerations |

|---|---|---|

| Foods & Consumables | Fruits, vegetables, meats, coffee, dairy | Low fat/oil content; stable frozen structure |

| Pharmaceuticals & Biologicals | Vaccines, antibiotics, proteins, bacteria | Requires process below glass transition temperature (Tg) |

| Advanced Materials & Research | Graphene aerogels, plant extracts, soil samples | Goal is to create a porous, dry structure |

| Unsuitable Materials | Pure honey, syrup, butter, pure oils | Lack a solid frozen matrix; prone to collapse |

Ready to Preserve Your Most Sensitive Materials?

Freeze-drying is a delicate process that requires precision equipment to ensure the stability and longevity of your products. Whether you are developing pharmaceuticals, preserving food, or creating advanced materials, KINTEK's laboratory freeze-dryers are engineered for reliability and exact control.

We specialize in providing lab equipment and consumables that meet the rigorous demands of research and production. Let our experts help you select the perfect solution for your specific application.

Contact KINTEK today to discuss your freeze-drying needs and discover how our solutions can enhance your results.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- What is the purpose of an evaporator? The Key Component That Creates Cooling