In short, steels that can be successfully hardened by quenching are those with sufficient carbon content. This includes most medium-carbon steels, high-carbon steels, alloy steels, tool steels, and specific grades of stainless steel. The ability to harden is not defined by the steel's name, but by its chemical composition, which dictates how it responds to rapid cooling.

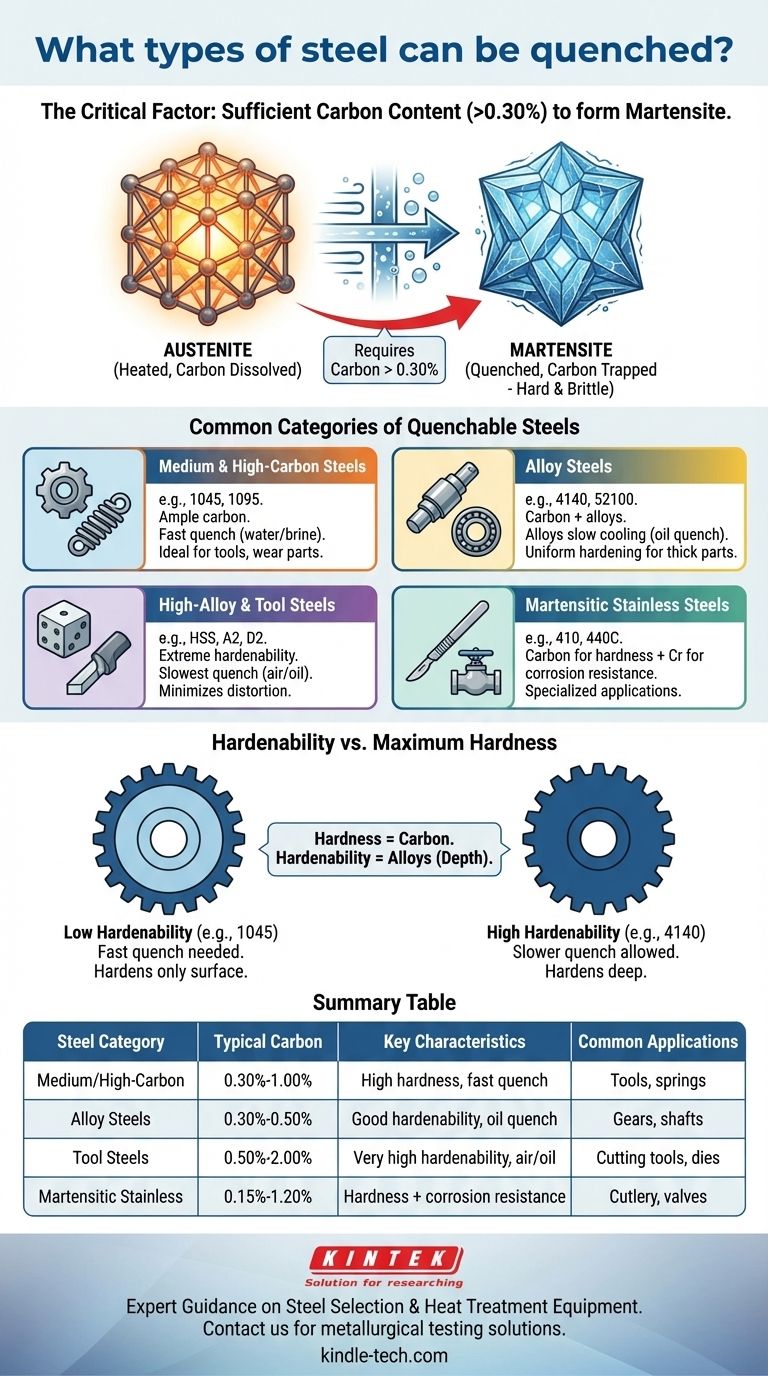

The critical factor determining if a steel can be quenched is its carbon content. While alloying elements determine how fast you must quench (the "hardenability"), a steel must contain enough carbon—typically above 0.30%—to form the hard, brittle microstructure known as martensite upon cooling.

The Fundamental Requirement for Quenching: Carbon

Quenching is a heat treatment process designed to lock in a specific atomic structure. The success of this process hinges almost entirely on one element: carbon.

Why Carbon is Essential

When steel is heated to a high temperature (a process called austenitizing), the iron atoms rearrange into a structure called austenite. This structure has the unique ability to dissolve a significant amount of carbon atoms within its lattice.

The Transformation to Martensite

If this austenite is cooled very rapidly (quenched), the carbon atoms are trapped. The iron lattice is forced to transform into a highly strained, hard, and brittle structure called martensite. This transformation is the basis of hardening steel.

The Minimum Carbon Threshold

Without enough dissolved carbon, the martensite transformation cannot occur effectively. Steels with very low carbon content will simply form softer, more ductile structures, regardless of how fast they are cooled.

A general rule is that a steel needs at least 0.30% to 0.35% carbon to achieve significant hardening through quenching.

Common Categories of Quenchable Steels

Based on the carbon principle, we can identify several major families of steel that are routinely quenched.

Medium and High-Carbon Steels

These are the most straightforward examples. Medium-carbon steels (e.g., AISI 1045) and high-carbon steels (e.g., AISI 1095) have ample carbon to form hard martensite, making them ideal for tools, springs, and wear parts.

Alloy Steels

Alloy steels like chromium-molybdenum (e.g., 4140) or bearing steels (e.g., 52100) contain carbon plus other elements like chromium, nickel, or manganese. These alloying elements don't increase the maximum hardness but critically slow down the required cooling rate.

High-Alloy and Tool Steels

This category includes high-speed steels (HSS), die steels, and other complex alloys. Their high concentration of alloying elements gives them extreme hardenability, allowing them to be hardened with a much slower quench, such as in oil or even still air, which reduces the risk of cracking and distortion.

Martensitic Stainless Steels

While many stainless steels (like the common 304 grade) are austenitic and cannot be hardened by quenching, a specific family can. Martensitic stainless steels (e.g., 410, 420, and 440C) are formulated with enough carbon to respond to heat treatment, combining corrosion resistance with high strength and hardness.

Understanding the Trade-offs: Hardenability vs. Hardness

It is critical to distinguish between maximum hardness and hardenability. They are not the same, and understanding the difference is key to process control.

Hardness is Determined by Carbon

The maximum achievable hardness of a steel is almost exclusively a function of its carbon content. A 1095 plain carbon steel and a complex HSS tool steel with the same carbon percentage will reach roughly the same peak hardness.

Hardenability is Determined by Alloys

Hardenability refers to the ability of a steel to be hardened to a certain depth. Alloying elements slow the transformation from austenite, giving you more time to cool the part before softer structures form.

A low-hardenability steel (like 1045) must be quenched extremely fast, meaning only a thin outer "skin" may fully harden on a thick part. A high-hardenability steel (like 4140 or an air-hardening tool steel) can be cooled more slowly, allowing the entire cross-section of a thick part to achieve full hardness.

Steels That Cannot Be Effectively Quenched

The most common examples are low-carbon steels (e.g., AISI 1018, A36). With carbon content often below 0.20%, they simply lack the raw material needed to form a significant amount of martensite, no matter how fast you quench them.

Making the Right Choice for Your Goal

Selecting the right steel and quench method depends entirely on the desired outcome, part geometry, and acceptable level of risk.

- If your primary focus is achieving high surface hardness on a simple part: A plain medium or high-carbon steel with a very fast water or brine quench is a cost-effective choice.

- If your primary focus is hardening a complex part or thick section uniformly: An alloy steel (like 4140 or 4340) is necessary, as its higher hardenability allows for a slower, less stressful oil quench.

- If your primary focus is minimizing distortion and cracking on a critical component: An air-hardening tool steel (like A2) provides the highest hardenability, allowing for the gentlest quench possible.

- If your primary focus is balancing hardness with corrosion resistance: A martensitic stainless steel (like 440C) is the only viable option.

Ultimately, successful hardening is about creating martensite by matching the steel's composition to a compatible cooling rate.

Summary Table:

| Steel Category | Typical Carbon Content | Key Characteristics | Common Applications |

|---|---|---|---|

| Medium/High-Carbon Steels (e.g., 1045, 1095) | 0.30% - 1.00% | High hardness, requires fast quench (water/brine) | Tools, springs, wear parts |

| Alloy Steels (e.g., 4140, 4340) | 0.30% - 0.50% | Good hardenability, oil quench, uniform hardening | Gears, shafts, structural components |

| Tool Steels (e.g., A2, D2, HSS) | 0.50% - 2.00% | Very high hardenability, air/oil quench, wear resistant | Cutting tools, dies, molds |

| Martensitic Stainless Steels (e.g., 410, 440C) | 0.15% - 1.20% | Combines hardness with corrosion resistance | Cutlery, valves, surgical instruments |

| Low-Carbon Steels (e.g., 1018, A36) | <0.30% | Cannot be effectively hardened by quenching | Structural components, machinery frames |

Need Expert Guidance on Steel Selection and Heat Treatment?

Choosing the right steel and quenching process is critical for achieving the desired hardness, durability, and performance in your components. The wrong choice can lead to part failure, cracking, or insufficient hardness.

KINTEK specializes in lab equipment and consumables for metallurgical testing, including furnaces for heat treatment processes like quenching. We help laboratories and manufacturers:

- Select the appropriate steel grades for specific applications

- Optimize heat treatment parameters for consistent results

- Ensure quality control with precise temperature management

Let our expertise guide your material decisions. Contact us today to discuss how we can support your laboratory's steel analysis and heat treatment needs.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Isostatic Molding Pressing Molds for Lab

- Double Plate Heating Press Mold for Lab

- Manual Lab Heat Press

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

People Also Ask

- What is the difference between manual and automatic heat press? Choose the Right Press for Your Precision Needs

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What are the pros and cons of hot forging? Unlock Superior Strength for Critical Components

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained