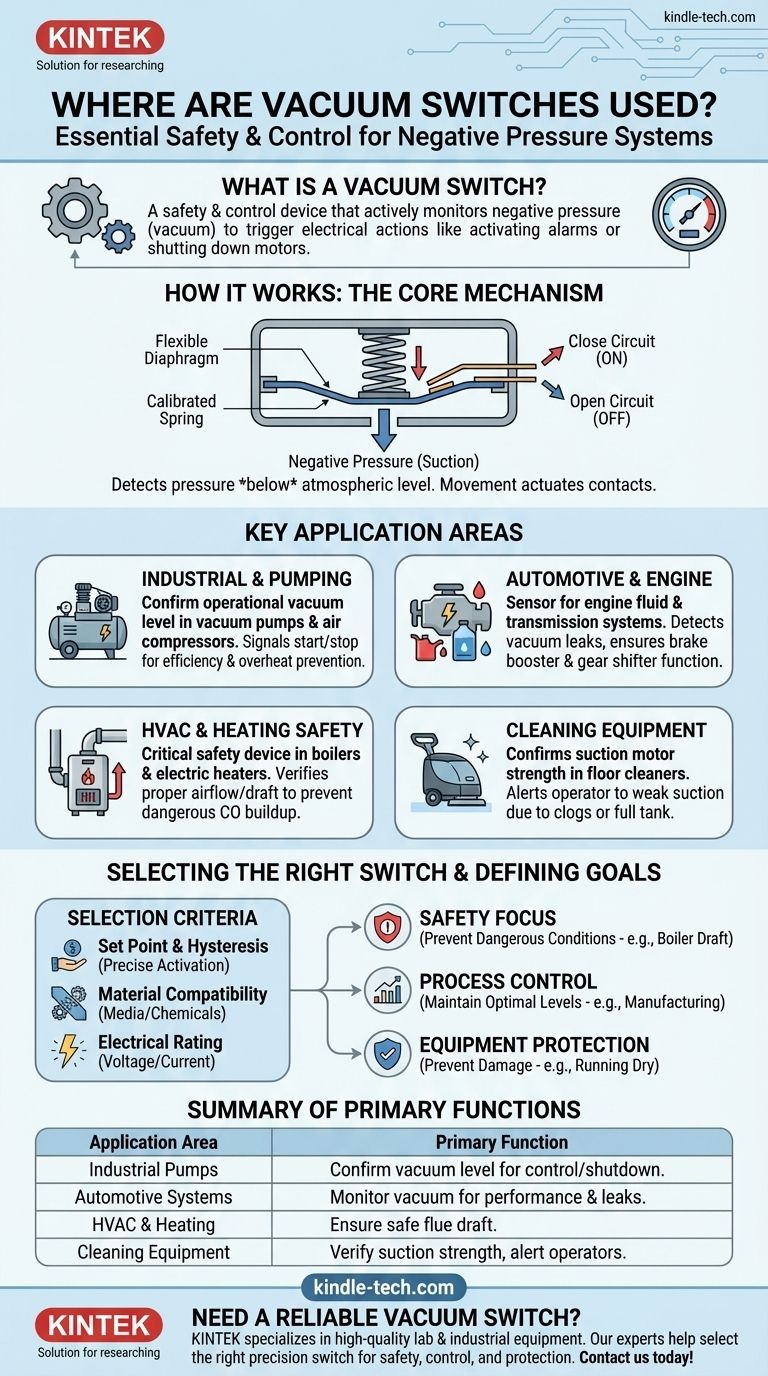

Vacuum switches are essential monitoring devices found in a wide array of systems that operate under negative pressure. Their applications range from industrial equipment like air compressors and vacuum pumps to everyday appliances such as floor cleaners and electric heaters, as well as critical automotive components like engine fluid and transmission systems.

A vacuum switch is fundamentally a safety and control mechanism. Its purpose is not just to be present in a system, but to actively monitor a specific level of negative pressure (a vacuum) and trigger an electrical action—like activating an alarm or shutting down a motor—when that pressure level is reached.

The Core Function: How a Vacuum Switch Works

A vacuum switch acts as a vigilant gatekeeper for systems that rely on suction or negative pressure. Its operation is straightforward but critical.

The Principle of Negative Pressure

Unlike a standard pressure switch that measures pressure above the atmospheric level, a vacuum switch is calibrated to detect pressure below it. It measures the "strength" of the suction.

The Internal Mechanism

Inside the switch, a flexible diaphragm is held in place by a calibrated spring. When a vacuum is applied, the atmospheric pressure on the outside of the diaphragm overcomes the spring's force, causing the diaphragm to move.

This movement physically actuates a set of electrical contacts. This can either close a circuit (turning something on) or open a circuit (shutting something off).

Unpacking the Practical Applications

Understanding why a vacuum switch is used in a specific application reveals its true value as a protective and control component.

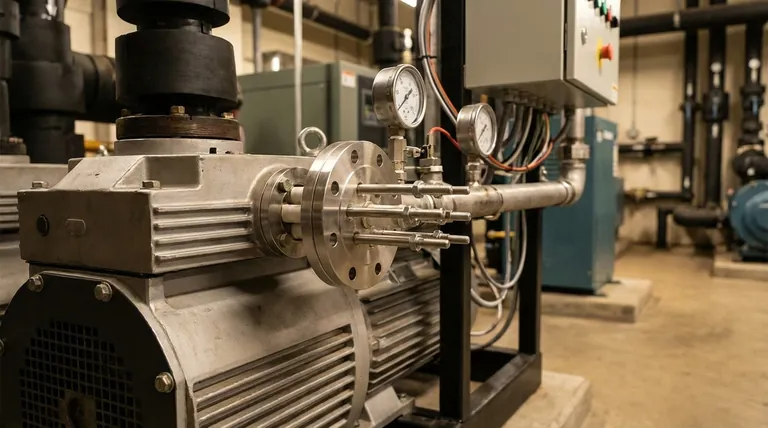

In Industrial and Pumping Systems

Applications like vacuum pumps and air compressors use vacuum switches to confirm that the system has reached its operational vacuum level. It can signal a controller to begin a process or shut down the pump to prevent it from running inefficiently or overheating once the target vacuum is achieved.

In Automotive and Engine Systems

In engine fluid and transmission systems, a vacuum switch can serve as a sensor. It might detect a vacuum leak, which could impair performance, or confirm that sufficient vacuum is present for components like brake boosters or vacuum-actuated gear shifters to function correctly.

For Safety in HVAC and Heating

In boilers and some electric heaters, a vacuum switch is a critical safety device. It verifies that there is proper airflow or draft through the exhaust flue. If the flue is blocked, the switch won't detect the necessary negative pressure and will prevent the boiler from firing, averting a dangerous buildup of carbon monoxide.

In Cleaning Equipment

For commercial floor cleaning equipment, a vacuum switch confirms that the suction motor is generating enough vacuum to effectively lift water and dirt from the floor. If the suction is weak (due to a clog or a full tank), the switch can trigger an indicator light to alert the operator.

Understanding the Trade-offs and Selection Criteria

Choosing the correct vacuum switch is not a one-size-fits-all decision. The integrity of your system depends on matching the switch to the specific operational demands.

Set Point and Hysteresis

The set point is the exact negative pressure at which the switch activates. This must be chosen carefully based on the system's requirements. Hysteresis, or the "deadband," is the difference between the activation and deactivation pressure, which prevents the switch from rapidly cycling on and off if the pressure hovers near the set point.

Material and Media Compatibility

The materials used for the diaphragm and housing (e.g., Nitrile, Viton, stainless steel) must be compatible with the media they will be exposed to, whether it's air, oil, water, or corrosive chemicals. Mismatched materials can lead to premature failure.

Electrical Rating

The switch's electrical contacts must be rated to handle the voltage and current of the circuit they are controlling. Using an underrated switch to control a high-power motor or heater will cause it to fail quickly and can create a fire hazard.

Making the Right Choice for Your Goal

To select the appropriate vacuum switch, you must first define its primary role within your system.

- If your primary focus is safety: Choose a robust, fail-safe switch designed to prevent a dangerous condition, such as ensuring proper draft in a boiler before ignition.

- If your primary focus is process control: Select a switch with a precise, adjustable set point to maintain optimal vacuum levels for a manufacturing or pumping operation.

- If your primary focus is equipment protection: Use a switch to monitor vacuum loss and automatically shut down a motor or pump, preventing damage from running dry or inefficiently.

Ultimately, a vacuum switch provides critical intelligence, turning a simple pressure reading into a decisive action that protects equipment, ensures safety, and enables control.

Summary Table:

| Application Area | Primary Function of Vacuum Switch |

|---|---|

| Industrial Pumps & Compressors | Confirms operational vacuum level for process control or shutdown. |

| Automotive Systems | Monitors engine/transmission vacuum for performance and leak detection. |

| HVAC & Heating Equipment | Ensures safe flue draft to prevent carbon monoxide buildup. |

| Cleaning Equipment | Verifies suction strength and alerts operators to clogs or full tanks. |

Need a reliable vacuum switch for your lab or industrial application? KINTEK specializes in high-quality lab equipment and consumables, including precision vacuum switches designed for safety, control, and equipment protection. Our experts can help you select the right switch for your specific pressure, media, and electrical requirements. Contact us today to ensure your system operates efficiently and safely!

Visual Guide

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- How do you maintain vacuum pressure? Master the balance between gas removal and gas load for stable performance.

- What are the different types of ovens in the lab? A Guide to Choosing the Right Heating Equipment

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- What instrument is used to measure vacuum? Selecting the Right Gauge for Your Pressure Range

- What is the calibration of a vacuum? Ensuring Accurate Pressure Measurement for Your Process