In the world of lab-grown diamonds, the "better" choice almost always comes down to the final quality of the stone, not just how it was made. However, the two primary manufacturing methods, HPHT and CVD, have distinct characteristics. While both produce real diamonds, stones grown using the High Pressure, High Temperature (HPHT) method are often considered superior as they tend to possess better intrinsic color and clarity without needing additional treatments.

The central challenge is not choosing between two brand names, but understanding how two different scientific processes result in diamonds with distinct starting qualities. While both HPHT and CVD can produce exceptional gems, the HPHT process generally yields a higher quality rough diamond from the outset.

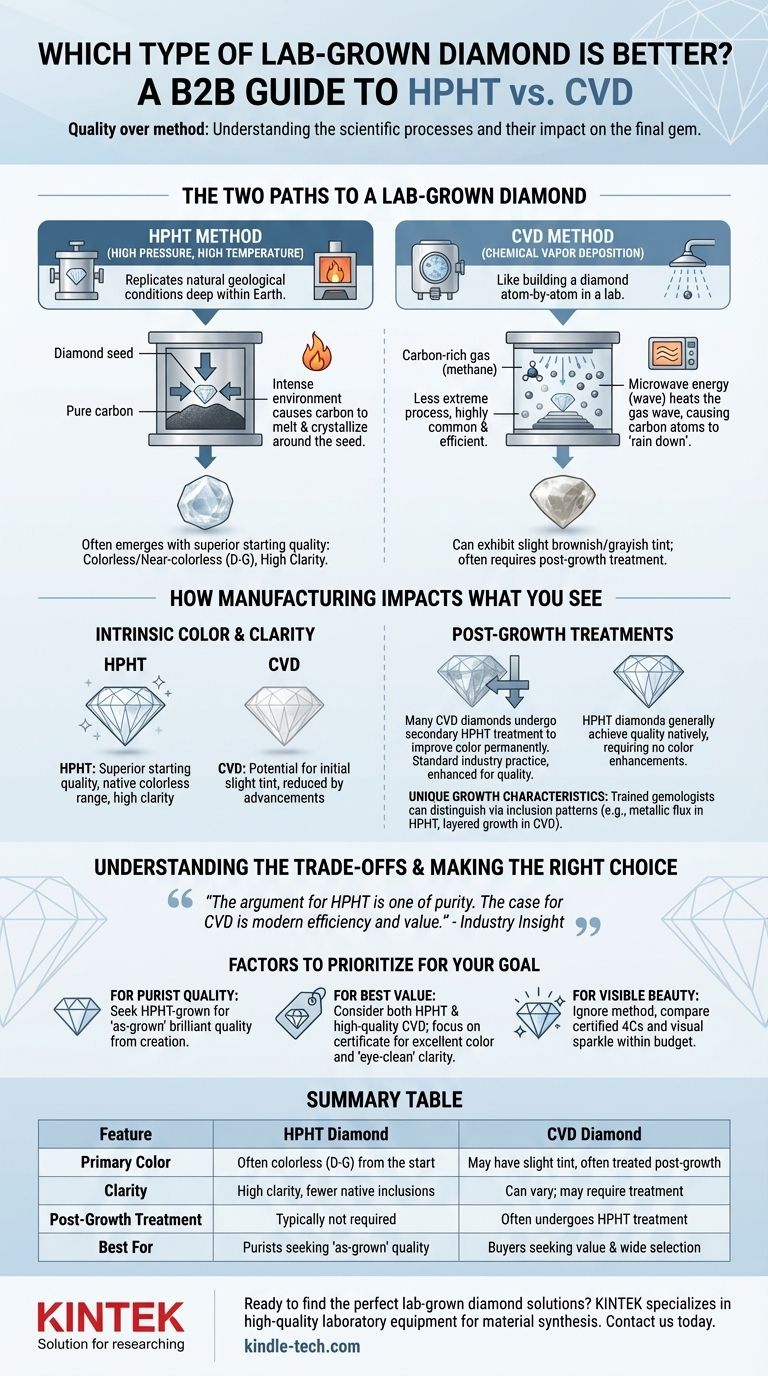

The Two Paths to a Lab-Grown Diamond

All lab-grown diamonds share the exact same chemical, physical, and optical properties as their mined counterparts. The difference lies in their origin story—a controlled laboratory environment that replicates one of two natural processes.

The HPHT Method (High Pressure, High Temperature)

The HPHT method mimics the natural geological conditions that form diamonds deep within the Earth. A small diamond "seed" is placed in a chamber with pure carbon and subjected to immense pressure and extreme heat.

This intense environment causes the carbon to melt and crystallize around the seed, growing a new, larger rough diamond. Because this process is so similar to nature, HPHT diamonds often emerge with high clarity and excellent color from the start.

The CVD Method (Chemical Vapor Deposition)

The CVD method is more like building a diamond atom-by-atom. A diamond seed is placed in a vacuum chamber filled with a carbon-rich gas, such as methane.

Microwave energy heats the gas, causing carbon atoms to break away and "rain down" onto the seed, building up the diamond in layers. This process is less extreme than HPHT and has become a very common and efficient way to grow diamonds.

How Manufacturing Impacts What You See

The method used to grow a diamond leaves subtle clues in its structure and can influence its final appearance, particularly its color.

Intrinsic Color and Clarity

HPHT diamonds are often celebrated for their superior starting quality. The process itself tends to produce stones in the colorless and near-colorless range (D-G grades) with high clarity.

CVD diamonds, on the other hand, can sometimes exhibit a slight brownish or grayish tint after their initial growth. While advancements have significantly reduced this, it's a known characteristic of the method.

The Role of Post-Growth Treatments

To eliminate any unwanted color, many CVD diamonds undergo a secondary treatment process after they are grown. This is often an HPHT treatment, where the grown CVD diamond is subjected to high pressure and heat to improve its color grade permanently.

This is a standard, accepted industry practice. However, it means you are buying a stone that was enhanced to achieve its quality, whereas an HPHT-grown diamond often achieves that quality natively.

Unique Growth Characteristics

A trained gemologist can distinguish between HPHT, CVD, and natural diamonds. Each type has unique inclusion patterns and crystal growth structures that act as a fingerprint of its origin.

For example, HPHT diamonds may contain metallic flux inclusions from the growth chamber, while CVD diamonds can show specific layered growth patterns. These differences have no impact on the diamond's beauty or durability.

Understanding the Trade-offs

Choosing a lab diamond isn't just about picking the "best" method, but understanding the value and quality implications of each.

Why HPHT is Often Considered "Better"

The argument for HPHT is one of purity. These diamonds are generally created with their high-quality characteristics already intact, requiring no further enhancements to improve their color. For buyers who value an "as-grown" stone, HPHT is the clear winner.

The Case for Modern CVD

CVD technology has advanced dramatically. Today's top-tier CVD producers create stunning, high-quality diamonds. A well-made and properly treated CVD diamond can be visually indistinguishable from an HPHT or a natural diamond. They are often available in a wide range of sizes and qualities, providing excellent market choice.

Beyond Method: Why the Certificate is King

Ultimately, the manufacturing method is secondary to the diamond's final, certified grade. A low-quality HPHT diamond is not better than a top-quality CVD diamond.

Factors like clarity grade (VS1 vs. VS2) are about the final quality, not the growth method. A VS1 diamond has fewer and smaller inclusions than a VS2, making it a higher clarity grade and thus more expensive, regardless of whether it is HPHT or CVD. Always prioritize the stone's 4Cs (Cut, Color, Clarity, Carat) as detailed on its grading report.

Making the Right Choice for Your Goal

Focus on the final certified quality of the stone while keeping its origin in mind as a secondary factor.

- If your primary focus is purist quality: Seek out an HPHT-grown diamond with a high color and clarity grade to ensure you are getting a stone that was brilliant from its creation.

- If your primary focus is finding the best value: Consider both HPHT and high-quality CVD diamonds, paying close attention to the certificate to ensure an excellent color grade and a clarity that is "eye-clean."

- If your primary focus is on the visible beauty: Ignore the growth method entirely and simply compare the certified 4Cs and the visual sparkle of the diamonds within your budget.

Armed with this knowledge, you can confidently choose the lab-grown diamond that delivers the beauty and quality you desire.

Summary Table:

| Feature | HPHT Diamond | CVD Diamond |

|---|---|---|

| Primary Color | Often colorless (D-G) from the start | May have a slight tint, often treated post-growth |

| Clarity | High clarity, fewer native inclusions | Can vary; may require treatment for high clarity |

| Post-Growth Treatment | Typically not required | Often undergoes HPHT treatment to improve color |

| Best For | Purists seeking 'as-grown' quality | Buyers seeking value and wide selection |

Ready to find the perfect lab-grown diamond for your needs? At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, including tools for advanced material synthesis. Whether you're researching diamond growth or need reliable lab solutions, our expertise ensures you get the precision and performance your work demands. Contact us today to discuss how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method