To ensure accurate and repeatable results, the electrodes of an electrolytic cell must be periodically maintained. Their performance degrades over time due to physical wear, surface contamination from reaction products, and chemical corrosion. While true "calibration" involves adjusting a device against a known standard, for an electrolytic cell, the process is fundamentally about systematic inspection and cleaning to restore the electrode surfaces to a known, effective state.

The term "calibration" for electrolytic cell electrodes can be misleading. The actual goal is to ensure experimental integrity by maintaining the physical and chemical condition of the electrode surfaces through a disciplined routine of inspection, cleaning, and proper handling.

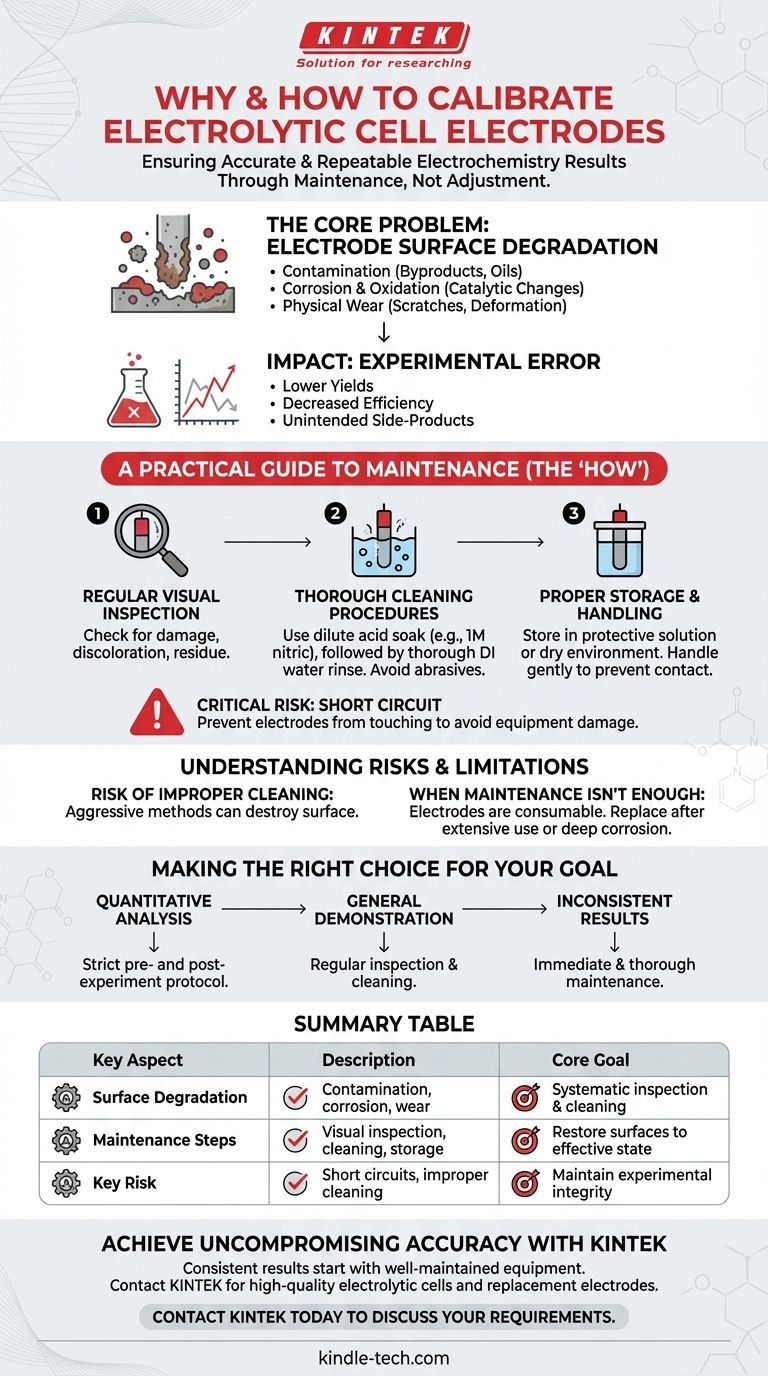

The Core Problem: Electrode Surface Degradation

The reliability of your entire electrolytic process depends on the condition of your electrodes. Because all chemical reactions occur on these surfaces, any change directly impacts your results.

Why Electrode Surfaces Are Critical

In an electrolytic cell, the anode is where oxidation occurs (losing electrons) and the cathode is where reduction occurs (gaining electrons). The efficiency, rate, and even the type of chemical reactions are dictated by the surface's material, topography, and cleanliness.

Causes of Performance Decline

Over time, electrode performance will inevitably decline. The primary causes are:

- Contamination: Reaction byproducts, oils, or other impurities can coat the electrode, blocking active sites and inhibiting electron transfer.

- Corrosion and Oxidation: Even relatively inert materials like platinum can slowly corrode or form oxide layers, changing their catalytic properties. Less noble metals are more susceptible.

- Physical Wear: Scratches or deformation from handling can alter the electrode's surface area, leading to inconsistent current density and reaction rates.

The Impact on Your Experiment

Degraded electrodes are a direct source of experimental error. This can manifest as lower-than-expected product yields, decreased reaction efficiency requiring more energy, or the formation of unintended side-products, compromising the purity of your results.

A Practical Guide to Electrode Maintenance (The "How")

Instead of a complex calibration procedure, ensuring electrode performance relies on a simple, consistent maintenance protocol. The specific steps can often be found in your electrode's instruction manual, but they follow a universal logic.

Step 1: Regular Visual Inspection

Before and after every use, inspect your electrodes. Look for any physical damage like bending or scratches, discoloration that might indicate oxidation or contamination, or any visible residue on the surface.

Step 2: Thorough Cleaning Procedures

Cleaning is the most critical step for restoring performance. The goal is to remove all surface contaminants without damaging the electrode itself.

A common method for noble metal electrodes, like platinum, is to soak them in a dilute acid (such as 1M nitric acid) to dissolve metallic impurities and organic residue. This is followed by a thorough rinse with deionized water to remove any lingering acid.

Step 3: Proper Storage and Handling

When not in use, electrodes must be stored properly. For metals prone to oxidation, this may mean immersing them in a protective solution or keeping them in a dry, oxygen-free container.

Always handle the cell and electrodes gently. Preventing the electrodes from touching is critical, as a short circuit can cause an extremely large current that will permanently damage the electrodes and potentially the power supply.

Understanding the Risks and Limitations

A proper maintenance routine is effective, but it comes with its own set of considerations to avoid causing more harm than good.

The Risk of Improper Cleaning

Using a cleaning method that is too aggressive can be destructive. Abrasive cleaners can scratch the electrode surface, while using the wrong chemical agent can cause the electrode itself to corrode. Always follow the manufacturer's recommended procedure.

The Danger of a Short Circuit

Carelessness during installation or cleaning can lead to the anode and cathode touching. This creates a short circuit, which will ruin your experiment and can present a significant safety hazard by overheating the components and damaging your equipment.

When Maintenance Isn't Enough

Electrodes are ultimately consumable items. After extensive use, significant physical wear, or deep corrosion, no amount of cleaning can restore their original performance. At this point, the only way to ensure accuracy is to replace them.

Making the Right Choice for Your Goal

To maintain the integrity of your experiments, adopt a maintenance routine based on the demands of your specific application.

- If your primary focus is quantitative analysis or high-purity synthesis: Implement a strict pre- and post-experiment cleaning and inspection protocol for maximum consistency.

- If your primary focus is general demonstration or educational purposes: Regular visual inspection and cleaning after every few uses may be sufficient to ensure the cell functions correctly.

- If you observe inconsistent results or decreased efficiency: This is a direct signal that immediate and thorough electrode maintenance is required before proceeding.

A disciplined approach to electrode maintenance is the foundation of reliable and repeatable electrochemistry.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Goal | Systematic inspection and cleaning to restore electrode surfaces to a known, effective state. |

| Primary Causes of Degradation | Contamination, corrosion/oxidation, and physical wear. |

| Maintenance Steps | 1. Visual Inspection, 2. Thorough Cleaning, 3. Proper Storage. |

| Key Risk | Short circuits from electrodes touching, which can damage equipment. |

Achieve Uncompromising Accuracy in Your Electrochemistry

Consistent, reliable results start with well-maintained equipment. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells and replacement electrodes, to serve your laboratory's precise needs.

Let our experts help you select the right equipment and establish best practices for maintenance.

Contact KINTEK today to discuss your specific requirements and ensure the integrity of your experiments.

Visual Guide

Related Products

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Copper Sulfate Reference Electrode for Laboratory Use

- Electrolytic Electrochemical Cell for Coating Evaluation

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What is the reference electrode for mercury mercurous sulfate? A Guide to Chloride-Free Electrochemistry

- Which type of electrode can be used as a reference point? Select the Right One for Accurate Measurements

- What are the characteristics of a saturated calomel electrode for neutral solutions? Understanding its stability and limitations.

- What is the reference electrode for mercury mercury chloride? Discover the Saturated Calomel Electrode (SCE)

- What are the four main types of sensors? A Guide to Power Source and Signal Type