In short, a vacuum is essential for thermal evaporation to ensure the evaporated material can travel directly to the target without interference and to prevent contaminants from ruining the final film. This process, a type of Physical Vapor Deposition (PVD), relies on creating a pristine environment where atoms can move in a straight line from the heated source to the substrate you wish to coat.

A vacuum does not pull atoms toward the substrate; it simply gets everything else out of the way. By removing residual gas molecules, the vacuum ensures a clear path for deposition and a clean surface for adhesion, which are the two non-negotiable requirements for creating a high-quality thin film.

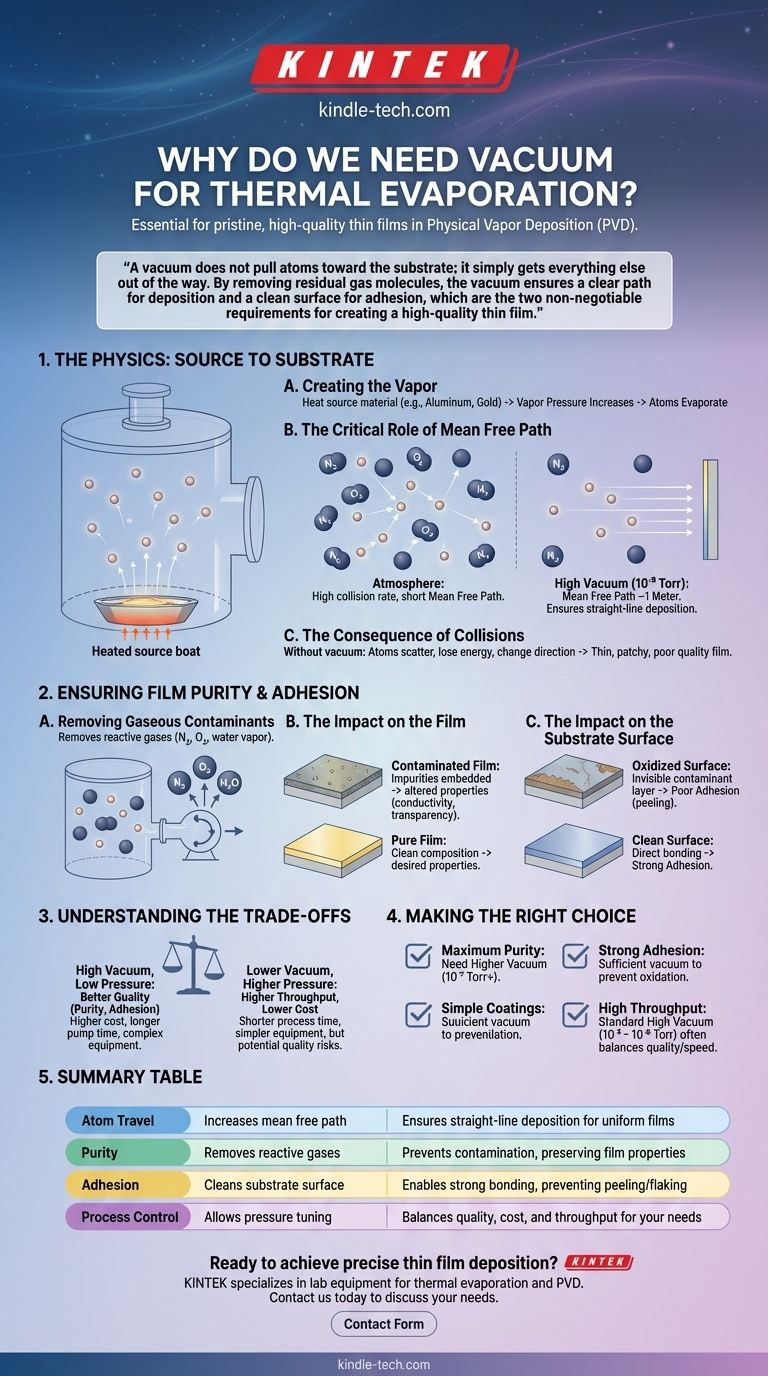

The Physics of Deposition: Source to Substrate

To understand the need for a vacuum, we must first visualize the journey of a single atom from its source material to its final destination on the substrate. The vacuum makes this journey possible.

Creating the Vapor

The process begins by heating a source material (like aluminum, gold, or chrome) inside the vacuum chamber. As the material heats, its vapor pressure increases until it begins to evaporate, releasing a stream of individual atoms or molecules.

The Critical Role of Mean Free Path

In a normal atmosphere, these newly freed atoms would immediately collide with billions of air molecules. A vacuum drastically reduces the number of these molecules. This increases the mean free path (MFP), which is the average distance an atom can travel before colliding with another particle.

At a typical high vacuum pressure of 10⁻⁵ Torr, the mean free path is roughly one meter. Since most deposition chambers are smaller than this, it effectively guarantees that the evaporated atoms travel in a straight, uninterrupted line from the source to the substrate.

The Consequence of Collisions

Without a sufficient vacuum, the evaporated atoms would be scattered by residual gas molecules. These collisions cause the atoms to lose energy, change direction, and fail to deposit uniformly on the target. The result is a thin, patchy, or non-existent film of poor quality.

Ensuring Film Purity and Adhesion

Beyond providing a clear path, the vacuum serves a second, equally critical function: ensuring the purity of the deposited film and its ability to stick to the substrate.

Removing Gaseous Contaminants

The air around us is primarily nitrogen and oxygen, with significant amounts of water vapor and other gases. These are active contaminants in a deposition process. A high vacuum is necessary to pump these reactive molecules out of the chamber.

The Impact of Contamination on the Film

If residual gases like oxygen are present during deposition, they can become embedded in the growing film. This can drastically alter the film's desired properties, such as its electrical conductivity, optical transparency, or chemical resistance.

The Impact on the Substrate Surface

For a film to adhere properly, it needs to bond directly to a clean substrate surface. A vacuum removes reactive gases that would otherwise form an invisible, ultra-thin layer (like an oxide layer) on the substrate. Deposition onto such a contaminated surface results in poor adhesion, causing the film to peel or flake off easily.

Understanding the Trade-offs

While a vacuum is essential, the level of vacuum required involves balancing quality against practical constraints. The pressure inside the chamber is a key process parameter.

Cost and Complexity

Achieving a "high vacuum" (around 10⁻⁵ to 10⁻⁷ Torr) requires sophisticated and expensive pump systems. Reaching an "ultra-high vacuum" (below 10⁻⁹ Torr) demands even more complex equipment, longer processing times, and higher costs.

Process Time vs. Quality

The lower the target pressure, the longer it takes to pump down the chamber. This directly impacts throughput. A key engineering decision is to determine the "good enough" vacuum level that meets quality requirements without making the process impractically slow.

Material Sensitivity

The required vacuum level depends heavily on the materials involved. Highly reactive source materials or substrates that oxidize easily demand a better vacuum to ensure a pure and well-adhered film.

Making the Right Choice for Your Goal

The optimal vacuum level is not a single number but is dictated by your final objective.

- If your primary focus is maximum film purity for optics or electronics: You need a higher vacuum (10⁻⁷ Torr or better) to minimize the incorporation of gaseous impurities into the film.

- If your primary focus is strong film adhesion: Your process must achieve a vacuum sufficient to prevent the substrate surface from reacting with residual gases like oxygen or water before deposition begins.

- If your primary focus is high throughput for simpler coatings: A standard high vacuum (10⁻⁵ to 10⁻⁶ Torr) often provides the best balance between film quality and process cycle time.

Ultimately, mastering the vacuum environment is the key to controlling the quality and performance of your final deposited film.

Summary Table:

| Aspect | Role of Vacuum | Benefit |

|---|---|---|

| Atom Travel | Increases mean free path | Ensures straight-line deposition for uniform films |

| Purity | Removes reactive gases | Prevents contamination, preserving film properties |

| Adhesion | Cleans substrate surface | Enables strong bonding, preventing peeling/flaking |

| Process Control | Allows pressure tuning | Balances quality, cost, and throughput for your needs |

Ready to achieve precise thin film deposition?

KINTEK specializes in lab equipment and consumables for thermal evaporation and other PVD processes. Our expertise ensures you get the right vacuum environment for your specific application—whether you prioritize film purity, adhesion, or high throughput.

Contact us today to discuss your laboratory needs and discover how our solutions can enhance your coating quality and efficiency!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are examples of heat treating? Master Annealing, Quenching, Tempering & Case Hardening

- What materials are sintering? Unlock the Potential of Metals, Ceramics, and Composites

- Why does evaporation need vacuum pressure? Gain Precise Control for Your Lab Processes

- What happens if proper clearance is not maintained between joints while brazing? Avoid Common Joint Failures

- Does heat treatment affect strength? Master the Art of Metal Property Control

- How does heat affect tensile strength? Understand the Strength-Ductility Trade-Off

- Why is temperature important in casting? Master the Thermal Balance for Defect-Free Parts

- What is the lowest possible vacuum pressure? Achieve Pristine Conditions for Your Lab