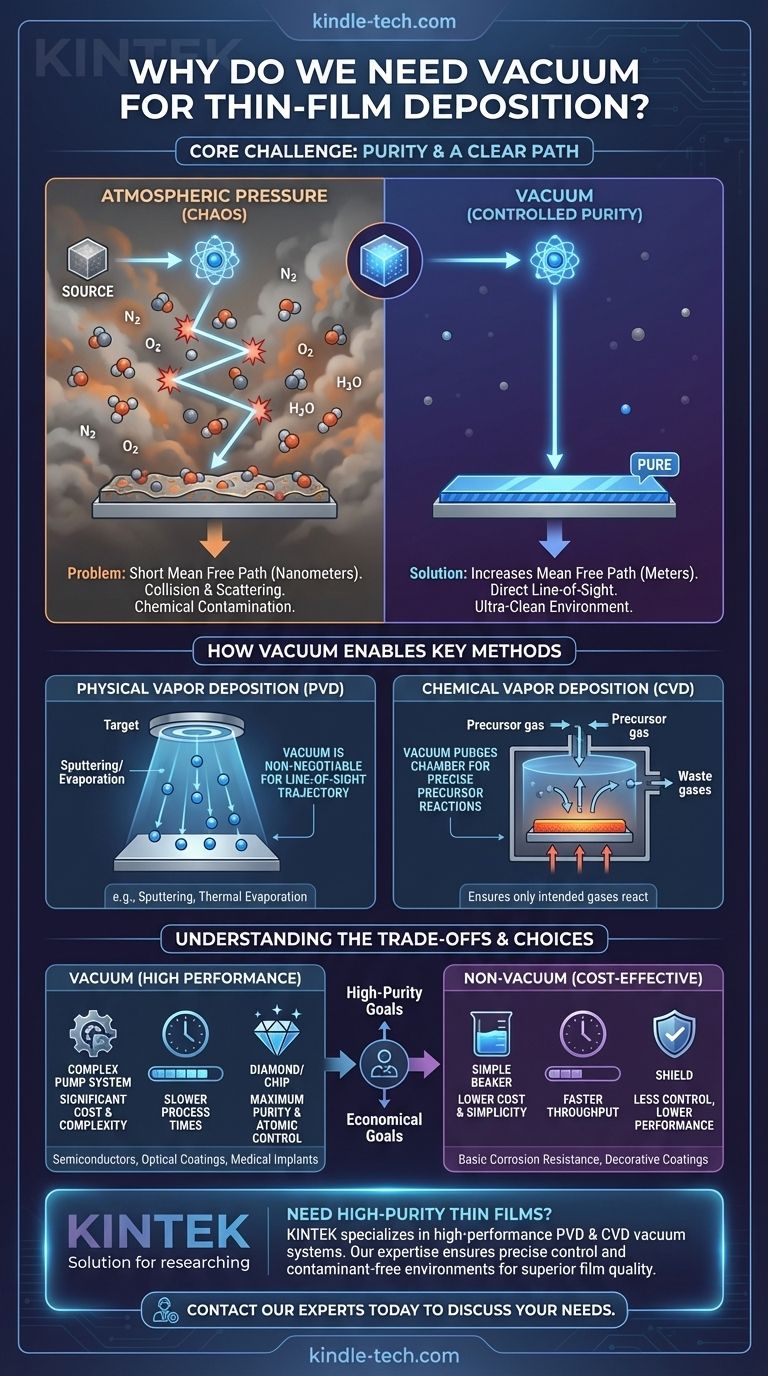

In thin-film deposition, a vacuum is not merely a passive condition; it is an active and essential tool. A vacuum is required to remove unwanted gas molecules—like oxygen, nitrogen, and water vapor—from the deposition chamber. Without it, these atmospheric particles would collide with the material being deposited, scattering it randomly and chemically contaminating the final film, thereby compromising its structural integrity and purity.

The fundamental purpose of a vacuum in thin-film deposition is to create a controlled, ultra-clean environment. This ensures that atoms from the source material can travel unimpeded to the substrate and that the resulting film is composed only of the intended material, free from impurities.

The Core Challenge: Purity and a Clear Path

To understand the need for a vacuum, we must first appreciate the microscopic scale of thin-film deposition. The process is essentially about building a new surface, one atomic layer at a time.

The Problem of Mean Free Path

At normal atmospheric pressure, a gas atom can only travel a few dozen nanometers before colliding with another gas atom. This distance is known as the mean free path.

For thin-film deposition, where the source material might be several centimeters from the substrate, this is a critical problem. In air, an atom leaving the source would be knocked off course almost immediately, preventing it from ever reaching its destination in a controlled manner.

By creating a vacuum, we drastically reduce the number of gas molecules in the chamber. This increases the mean free path from nanometers to meters, allowing deposition atoms to travel in a straight, predictable line from the source to the substrate.

The Threat of Chemical Contamination

Atmospheric air is reactive. Gases like oxygen and water vapor will readily react with most materials, especially at the high temperatures often used in deposition.

If these reactive gases are present, they will incorporate themselves into the growing film, creating unwanted compounds like oxides. This contamination can dramatically alter the film's desired properties, such as its electrical conductivity, optical transparency, or hardness.

A vacuum removes these contaminants, ensuring that the film's chemistry is pure and precisely controlled.

How Vacuum Enables Key Deposition Methods

Different deposition techniques rely on the vacuum for slightly different reasons, but the underlying principles of a clear path and high purity remain constant.

For Physical Vapor Deposition (PVD)

PVD methods like sputtering or thermal evaporation involve physically dislodging atoms from a source material (the "target") and having them travel to coat a substrate.

These methods are fundamentally dependent on a "line-of-sight" trajectory. The vacuum is non-negotiable because it provides the clear, unobstructed path necessary for atoms to travel directly from the target to the substrate.

For Chemical Vapor Deposition (CVD)

CVD works by introducing specific precursor gases into a chamber, which then react on a heated substrate to form the desired film.

While it may seem counterintuitive to use a vacuum when you are just going to add gases back in, the initial vacuum step is crucial. It purges the chamber of all unwanted atmospheric gases. This ensures that the only molecules present are the precise precursor gases required for the intended chemical reaction, leading to a film of extremely high purity.

Understanding the Trade-offs

While essential for high-performance films, implementing a vacuum environment is not without its challenges. It is a deliberate engineering choice with significant implications.

Significant Cost and Complexity

Creating and maintaining a high vacuum requires specialized and expensive equipment. This includes robust vacuum chambers, a series of pumps (e.g., roughing pumps and turbomolecular pumps), and precise gauges to monitor the pressure.

This complexity adds significant cost and requires specialized expertise to operate and maintain.

Slower Process Times

Pumping a chamber down to the required vacuum level takes time. This "pump-down" cycle can be a bottleneck in a manufacturing process, limiting throughput and scalability compared to processes that operate at atmospheric pressure.

The Alternative: Non-Vacuum Methods

It's important to recognize that not all thin-film deposition requires a vacuum. Methods like the chemical bath deposition or electroplating operate in a liquid solution at normal atmospheric pressure.

These methods are often simpler and cheaper but offer far less control over film purity, uniformity, and structure. They are suitable for applications where the absolute performance of a vacuum-deposited film is not required.

Making the Right Choice for Your Goal

The decision to use a vacuum is directly tied to the required quality and performance of the final thin film.

- If your primary focus is maximum purity and performance (e.g., semiconductors, optical coatings, medical implants): A vacuum-based process like PVD or CVD is non-negotiable for achieving the required atomic-level control.

- If your primary focus is cost-effective surface protection (e.g., basic corrosion resistance or decorative coatings): A non-vacuum method like chemical bath deposition or electroplating may be a more practical and economical choice.

Ultimately, choosing a vacuum process is a commitment to controlling the deposition environment at the most fundamental level, enabling the creation of advanced materials that would be impossible to form under any other condition.

Summary Table:

| Key Role of Vacuum | Benefit |

|---|---|

| Increases Mean Free Path | Allows atoms to travel directly from source to substrate |

| Prevents Chemical Contamination | Removes reactive gases (O₂, H₂O) for pure film chemistry |

| Enables Line-of-Sight Deposition | Critical for PVD methods like sputtering and evaporation |

| Controls Reaction Environment | Essential for CVD to ensure only intended precursor gases react |

Need to achieve high-purity thin films for your research or production?

KINTEK specializes in high-performance lab equipment, including vacuum systems for PVD and CVD processes. Our expertise ensures you get the precise control and contaminant-free environment required for superior film quality in semiconductors, optics, and advanced materials.

Contact our experts today to discuss your specific thin-film deposition needs and find the perfect vacuum solution for your laboratory.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications