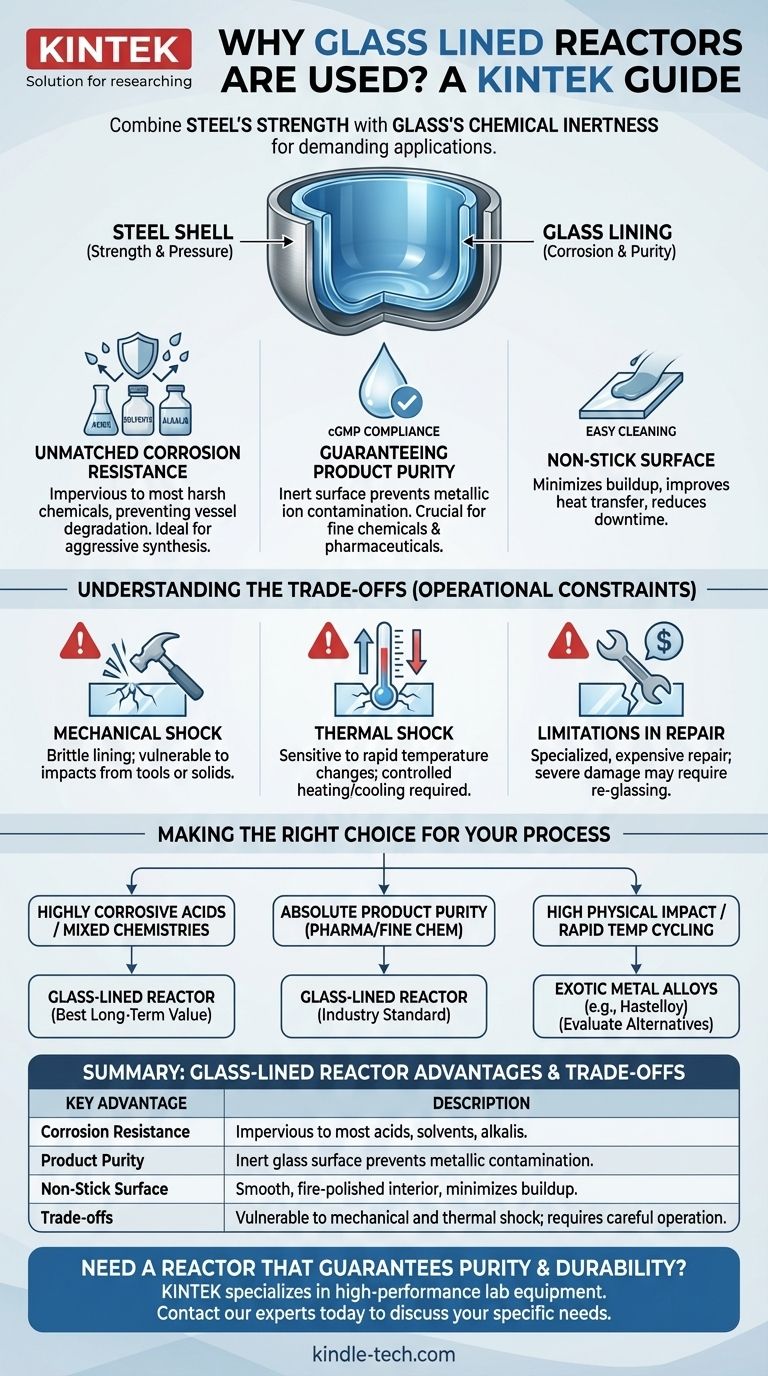

In short, glass-lined reactors are used because they combine the structural strength and pressure resistance of steel with the superior corrosion resistance and chemical inertness of glass. This unique combination makes them essential for processes involving highly aggressive chemicals or requiring extreme product purity, such as in the fine chemical and biopharmaceutical industries.

The core problem in advanced chemical manufacturing is containing aggressive reactions without the vessel itself corroding or contaminating the final product. A glass-lined reactor solves this by fusing a specialized glass layer to the interior of a steel tank, creating an ideal environment for harsh synthesis and high-purity applications where metal alloys would fail.

The Core Principle: A Shield of Inertness

A glass-lined reactor is not simply a steel tank with a glass insert; it is a composite material. A layer of specialized glass formulation is fused to the steel surface at high temperatures, creating a strong, integrated bond. This creates a surface with unique advantages.

Unmatched Corrosion Resistance

The primary reason for using a glass lining is its exceptional resistance to corrosion from a vast range of chemicals.

It is virtually impervious to all acids (except hydrofluoric acid), solvents, and most alkaline solutions at a wide range of concentrations and temperatures. This allows for processes that would rapidly destroy even high-grade stainless steel or other expensive alloys.

Guaranteeing Product Purity

In industries like pharmaceuticals, food production, and specialty chemicals, even trace amounts of metallic contamination can ruin a batch or render a product unsafe.

The glass surface is extremely inert and does not leach metal ions into the product. This ensures the purity, color, and stability of the final substance, which is a non-negotiable requirement for cGMP (Current Good Manufacturing Practice) compliant operations.

The Advantage of a Non-Stick Surface

The smooth, fire-polished glass surface minimizes adhesion of viscous or sticky materials. Think of it as a high-performance, industrial-grade non-stick cooking pan.

This anti-stick property prevents product buildup on the reactor walls, which improves heat transfer efficiency and makes the reactor significantly easier and faster to clean between batches. This reduces downtime and the risk of cross-contamination.

Understanding the Trade-offs

While powerful, glass-lined reactors are not indestructible. Their primary benefits are balanced by significant operational constraints that must be respected to prevent catastrophic failure.

Vulnerability to Mechanical Shock

The glass lining is hard but brittle. Dropping tools, components, or even the solid form of a reactant into the vessel can easily chip or crack the lining, exposing the steel underneath.

Once the steel is exposed, aggressive corrosion will begin immediately, undermining the surrounding glass and leading to equipment failure.

Sensitivity to Thermal Shock

The steel shell and the glass lining have different rates of thermal expansion. Rapidly changing the temperature—for instance, by introducing a very cold liquid into a hot reactor—can create stresses that exceed the glass's tensile strength, causing it to crack.

All heating and cooling operations must be gradual and controlled within the manufacturer's specified limits to prevent this damage.

Limitations in Repair

Repairing a damaged glass lining is a specialized and expensive process. Small chips can sometimes be repaired in the field using plugs made of tantalum (a highly corrosion-resistant metal), but larger failures may require the entire vessel to be returned to the manufacturer for re-glassing.

Making the Right Choice for Your Process

Deciding whether to use a glass-lined reactor is a critical engineering decision based on the specific demands of your chemical process.

- If your primary focus is handling highly corrosive acids or mixed-acid chemistries: A glass-lined reactor is almost certainly the correct and most cost-effective long-term choice.

- If your primary focus is absolute product purity for pharmaceuticals or fine chemicals: A glass-lined reactor is the industry standard for preventing metallic ion contamination.

- If your process involves high physical impact or requires extremely rapid temperature cycling: You should carefully evaluate alternatives like reactors made from Hastelloy or other exotic metal alloys, as the risk of damage to a glass lining may be too high.

Ultimately, choosing a glass-lined reactor is a strategic decision to prioritize chemical resistance and product purity above mechanical robustness.

Summary Table:

| Key Advantage | Description |

|---|---|

| Corrosion Resistance | Impervious to most acids, solvents, and alkalis, protecting against vessel degradation. |

| Product Purity | Inert glass surface prevents metallic ion contamination, crucial for cGMP compliance. |

| Non-Stick Surface | Smooth, fire-polished interior minimizes buildup, improves cleaning, and enhances heat transfer. |

| Trade-offs | Vulnerable to mechanical and thermal shock; requires careful operation and specialized repair. |

Need a Reactor That Guarantees Purity and Durability?

Choosing the right reactor is critical for your process efficiency and product quality. KINTEK specializes in high-performance lab equipment, including reactors designed for demanding chemical applications.

We understand the challenges of handling aggressive chemicals and maintaining strict purity standards. Our expertise can help you select the ideal equipment to enhance your lab's productivity and ensure batch-to-batch consistency.

Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can support your laboratory's success.

Visual Guide

Related Products

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Why is a High-temperature and High-pressure Autoclave necessary for zirconium alloy testing? Ensure Nuclear Safety.

- How does a high-pressure hydrothermal autoclave facilitate the synthesis of BiVO4@PANI nanocomposites? Unlock Precision.

- What is the function of high-pressure reactors in semiconductor catalyst preparation? Optimize Your Heterojunctions

- What is the function of a high-pressure static autoclave in biomass HTL? Optimize Your Biomass Conversion Research

- Which critical experimental conditions does a high-pressure autoclave provide? Optimize Mixed Sulfide Leaching