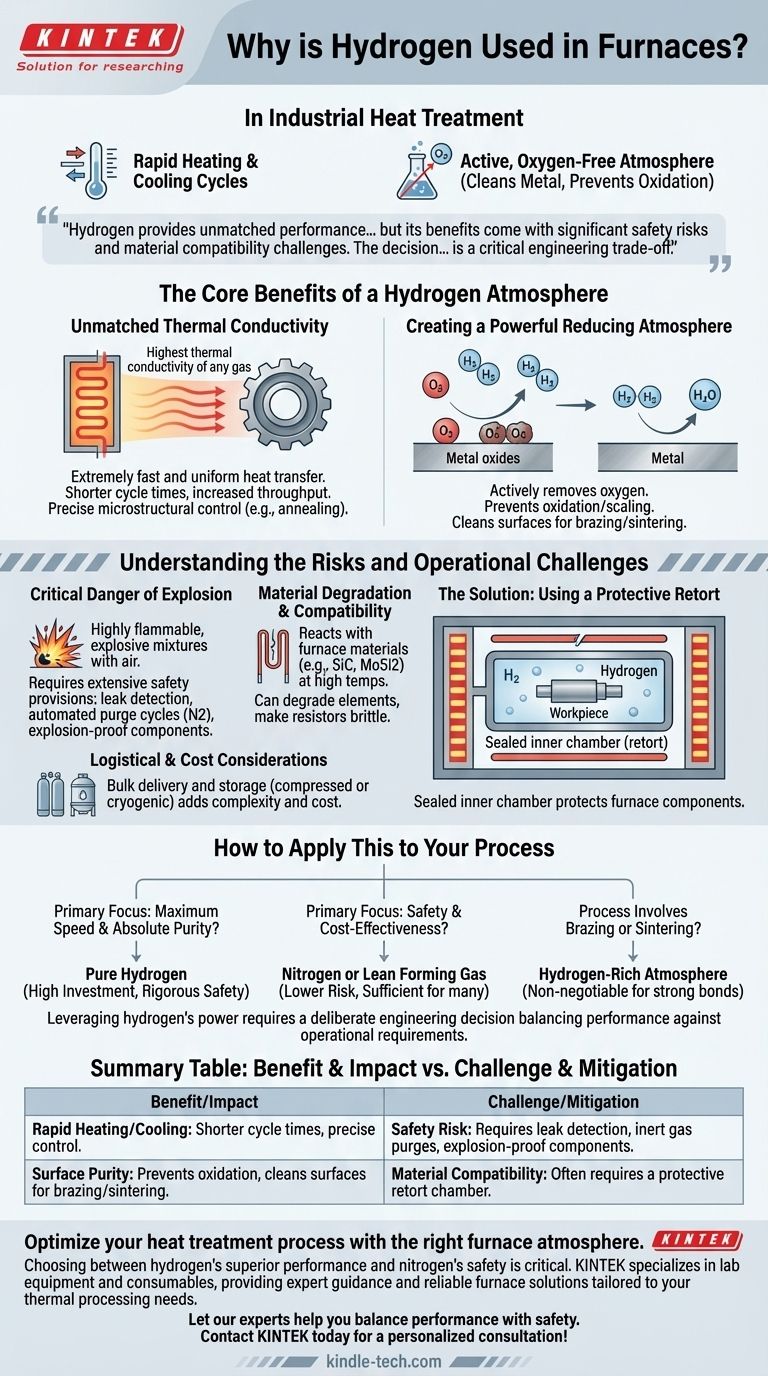

In industrial heat treatment, hydrogen is used in furnaces for two primary reasons: its exceptionally high thermal conductivity allows for rapid heating and cooling cycles, and its chemical reactivity creates an active, oxygen-free atmosphere that cleans metal surfaces and prevents oxidation. These properties make it invaluable for processes requiring high precision and surface purity.

Hydrogen provides unmatched performance for specific thermal processes, but its benefits come with significant safety risks and material compatibility challenges. The decision to use it is a critical engineering trade-off between process capability and operational complexity.

The Core Benefits of a Hydrogen Atmosphere

The use of hydrogen is not arbitrary; it is chosen for distinct physical and chemical advantages that other gases cannot offer.

Unmatched Thermal Conductivity for Rapid Processing

Hydrogen gas has the highest thermal conductivity of any gas. This physical property is a significant process advantage.

It allows for extremely fast and uniform heat transfer to the parts being treated. This accelerates both heating and cooling (quenching), which can dramatically shorten cycle times and increase furnace throughput.

This rapid thermal response also enables precise control over the material's final microstructure and mechanical properties, which is critical in processes like metal annealing.

Creating a Powerful Reducing Atmosphere

In furnace terminology, a reducing atmosphere is one that actively removes oxygen. Hydrogen is a powerful reducing agent.

At high temperatures, hydrogen gas (H₂) readily reacts with any oxygen (O₂) present, forming water vapor (H₂O) that is then vented. This prevents the metal parts from oxidizing or scaling during the high-temperature process.

Even more, hydrogen can react with and remove existing oxides from the metal's surface, effectively cleaning the part. This is essential for applications like brazing, where perfectly clean surfaces are required for the filler metal to bond properly.

Understanding the Risks and Operational Challenges

The benefits of hydrogen are paired with considerable operational demands and hazards that must be managed with specialized engineering and strict protocols.

The Critical Danger of Explosion

Hydrogen is highly flammable and can form explosive mixtures with air. This is the single greatest risk associated with its use in furnaces.

Consequently, any furnace system using pure hydrogen or hydrogen-rich blends (forming gas) must be equipped with extensive, often expensive, safety provisions. These include leak detection, automated purge cycles with inert gas (like nitrogen), and explosion-proof components.

Material Degradation and Compatibility

Hydrogen is not inert. At high temperatures, its reactivity can be destructive to the furnace itself.

Heating elements made from common materials like silicon carbide (SiC) or molybdenum disilicide (MoSi₂) can be chemically attacked and degraded by a pure hydrogen atmosphere. Other metallic components, such as resistors, can become brittle over time.

The Solution: Using a Protective Retort

To mitigate material degradation, high-temperature hydrogen furnaces often use a retort. This is a sealed inner chamber, typically made of a specialized metal alloy.

The retort contains the hydrogen atmosphere and the workpiece, physically separating them from the furnace's primary insulation and heating elements. This protects the vulnerable components from chemical attack and enhances the safety and longevity of the furnace.

Logistical and Cost Considerations

Unlike nitrogen, which can often be generated on-site, hydrogen must typically be delivered and stored in bulk, either as a compressed gas or a cryogenic liquid. This adds logistical complexity and cost to the operation.

How to Apply This to Your Process

Choosing the right furnace atmosphere depends entirely on your process requirements, balancing performance against safety and cost.

- If your primary focus is maximum process speed and absolute surface purity: The superior thermal and reducing properties of pure hydrogen are likely necessary, but require a significant investment in a specialized furnace and rigorous safety protocols.

- If your primary focus is safety and cost-effectiveness: A nitrogen-based atmosphere or a lean forming gas (e.g., 5% hydrogen, 95% nitrogen) may provide sufficient oxidation prevention for many applications with a much lower risk profile.

- If your process involves brazing or sintering: The active cleaning and oxide reduction from a hydrogen-rich atmosphere is often a non-negotiable requirement for achieving strong, reliable metallurgical bonds.

Ultimately, leveraging hydrogen's power requires a deliberate engineering decision that balances its exceptional performance against its demanding operational requirements.

Summary Table:

| Benefit | Key Characteristic | Impact on Process |

|---|---|---|

| Rapid Heating/Cooling | Highest thermal conductivity of any gas | Shorter cycle times, precise microstructural control |

| Surface Purity | Powerful reducing agent (removes oxygen) | Prevents oxidation, cleans metal surfaces for brazing/sintering |

| Operational Consideration | Key Challenge | Mitigation Strategy |

| Safety Risk | Highly flammable/explosive | Requires leak detection, inert gas purges, explosion-proof components |

| Material Compatibility | Can degrade furnace components | Often requires a protective retort chamber |

Optimize your heat treatment process with the right furnace atmosphere.

Choosing between hydrogen's superior performance and the safety of nitrogen-based alternatives is a critical decision for your lab's efficiency and safety. KINTEK specializes in lab equipment and consumables, providing expert guidance and reliable furnace solutions tailored to your specific thermal processing needs—whether you require the rapid, pure results of hydrogen or a safer, cost-effective alternative.

Let our experts help you balance performance with safety. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- Why are laboratory vacuum or atmosphere furnaces necessary for non-gold metallic nanofoams? Ensure Material Integrity

- What are the inert gases in a heat treatment furnace? Choose the Right Shield for Your Metal

- What is the necessity of integrating an analytical balance with an atmosphere furnace for TGA? Mastering Kinetic Data

- What gases are used in brazing? Optimize Your Brazing Process with the Right Atmosphere

- What are the primary functions of a controlled atmosphere reactor? Master Pure Steel Synthesis and Reaction Stability

- How does the atmosphere affect sintering? Master Final Part Quality with Controlled Atmospheres

- How does a hydrogen stove work? A Guide to Clean Cooking Technology

- What role does a high-temperature atmosphere furnace play in 3D Graphene Oxide production? Unlock Advanced Exfoliation