To preserve the most delicate biological drugs, freeze drying is the ideal method because it removes water at low temperatures through sublimation, a process that avoids the structural damage caused by heat or conventional freezing. This gentle dehydration locks the drug's complex molecular structure in place, preserving its biological activity and ensuring its effectiveness when it reaches the patient.

The core challenge in pharmaceutical manufacturing is preventing sensitive biological molecules, like proteins and vaccines, from degrading. Freeze drying (lyophilization) solves this by transforming the product into a stable, dry powder without the damaging effects of heat, thereby guaranteeing its long-term stability and potency.

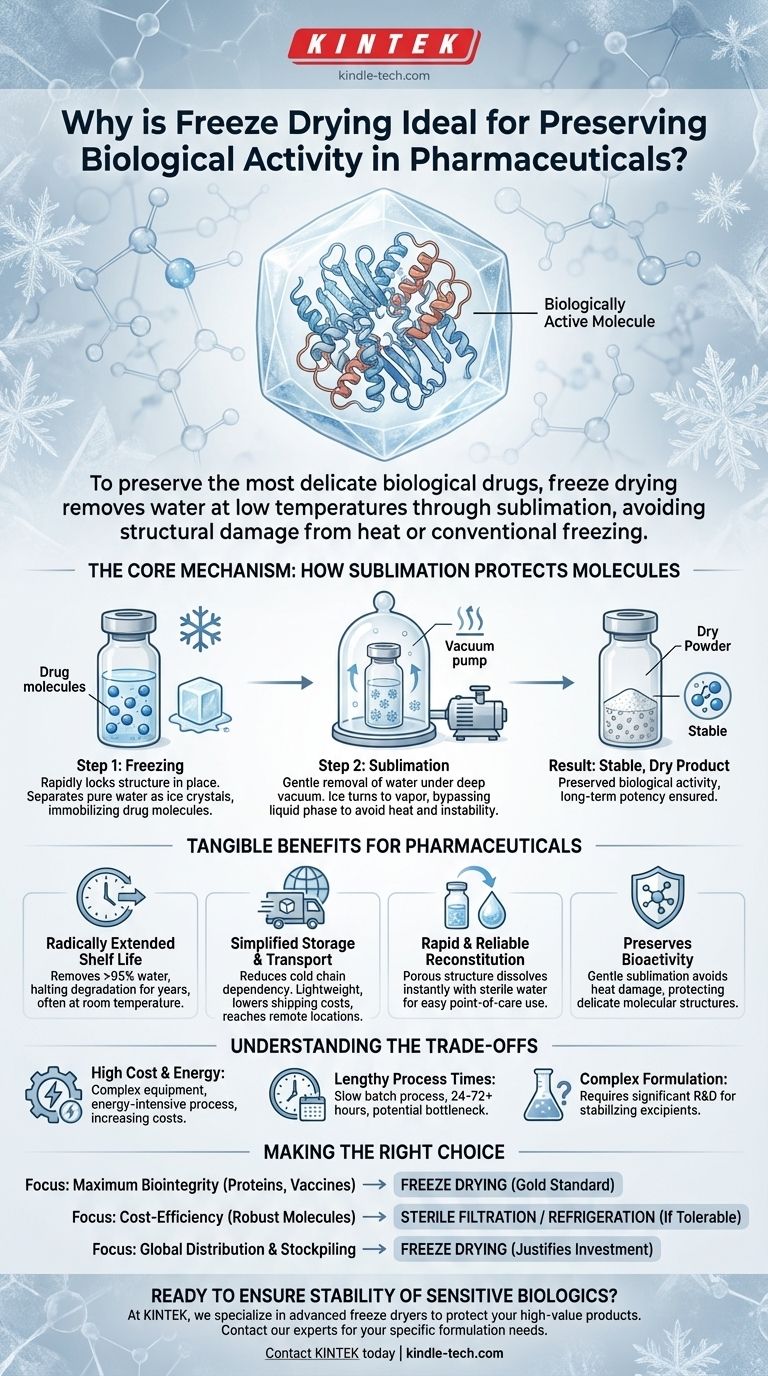

The Core Mechanism: How Sublimation Protects Molecules

To understand why freeze drying is so effective, we must first understand the enemies of biological drugs: heat and water.

The Problem with Water and Heat

Most biological drugs, such as antibodies and vaccines, are produced in a water-based solution. While necessary for their creation, water also enables chemical reactions that cause these complex molecules to break down over time.

Heat is a conventional method for removing water, but it is destructive. High temperatures cause the delicate, folded structures of proteins to unravel (denature), permanently destroying their biological function.

Step 1: Freezing to Lock Structure in Place

The first step in freeze drying is to rapidly freeze the drug solution. This process immobilizes the drug molecules, locking their fragile, three-dimensional structures into a solid ice matrix.

This initial freezing is critical. It separates the pure water (as ice crystals) from the drug molecules, preparing the product for dehydration without allowing the molecules to degrade.

Step 2: Sublimation - The Gentle Removal of Water

This is the key step that sets freeze drying apart. The frozen product is placed under a deep vacuum.

Under these low-pressure conditions, the ice crystals turn directly into water vapor without first melting into a liquid. This physical process is called sublimation.

By bypassing the liquid phase entirely, sublimation removes the water while keeping the product frozen and at a low temperature. This avoids both the chemical instability of a liquid solution and the structural damage of heat drying.

The Tangible Benefits for Pharmaceuticals

This unique preservation mechanism delivers several powerful advantages for drug manufacturing, storage, and delivery.

Radically Extended Shelf Life

By removing over 95% of the water, freeze drying effectively halts the chemical and biological processes that cause degradation.

This transforms an unstable liquid drug that might last for weeks into a stable powder that can be stored for many years, often without refrigeration.

Simplified Storage and Transport

Many liquid biologicals require a constant "cold chain"—unbroken refrigeration from factory to clinic—which is expensive and logistically complex.

Freeze-dried products are often stable at room temperature. They are also lightweight, drastically reducing shipping costs and making it easier to supply medications to remote or challenging locations.

Rapid and Reliable Reconstitution

The sublimation process creates a porous, sponge-like structure in the dried product.

This structure allows the powder to be reconstituted (redissolved) almost instantly with sterile water just before administration, ensuring the drug is prepared correctly and easily at the point of care.

Understanding the Trade-offs

Despite its clear advantages, freeze drying is not a universal solution. It involves significant considerations that make it suitable only for high-value, sensitive products.

High Cost and Energy Consumption

Freeze dryers are complex, expensive pieces of equipment. The process itself is also very energy-intensive due to the deep vacuum and temperature control required, increasing manufacturing costs.

Lengthy Process Times

A single freeze-drying cycle can take anywhere from 24 to 72 hours, or even longer. This slow batch process can be a bottleneck in high-volume manufacturing compared to faster, continuous drying methods.

Complex Formulation Development

Not every drug formulation can be successfully freeze-dried. Significant research and development are required to select the right stabilizing excipients (inactive ingredients) that protect the active drug molecule from the stresses of freezing and drying.

Making the Right Choice for Your Product

Deciding on a preservation method requires balancing the product's sensitivity against manufacturing and logistical realities.

- If your primary focus is maximum biological integrity for a highly sensitive product: Freeze drying is the gold standard for preserving complex proteins, antibodies, and vaccines.

- If your primary focus is cost-efficiency for a more robust molecule: Simpler methods like sterile filtration and refrigeration may be sufficient if the product can tolerate them for its required shelf life.

- If your primary focus is global distribution and long-term stockpiling: The stability and reduced cold-chain requirements of a freeze-dried product often justify the higher initial manufacturing cost.

Ultimately, freeze drying provides unparalleled protection for the most valuable and sensitive biologic drugs, ensuring their efficacy from the moment of manufacture to the point of patient care.

Summary Table:

| Key Advantage | Description |

|---|---|

| Preserves Bioactivity | Gentle sublimation process avoids heat damage, protecting delicate molecular structures. |

| Extends Shelf Life | Removes >95% water, transforming unstable liquids into stable powders for years. |

| Simplifies Logistics | Often stable at room temperature, reducing cold chain dependency and shipping costs. |

| Ensures Easy Use | Porous structure allows for rapid and reliable reconstitution with sterile water. |

Ready to ensure the stability and potency of your sensitive biologics?

At KINTEK, we specialize in providing advanced laboratory equipment, including freeze dryers (lyophilizers) designed to meet the rigorous demands of pharmaceutical development and manufacturing. Our solutions help you protect your high-value proteins, vaccines, and other biological products, guaranteeing their efficacy from production to patient.

Let our experts help you select the ideal equipment for your specific formulation needs. Contact KINTEK today to discuss how we can support your critical preservation processes.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization