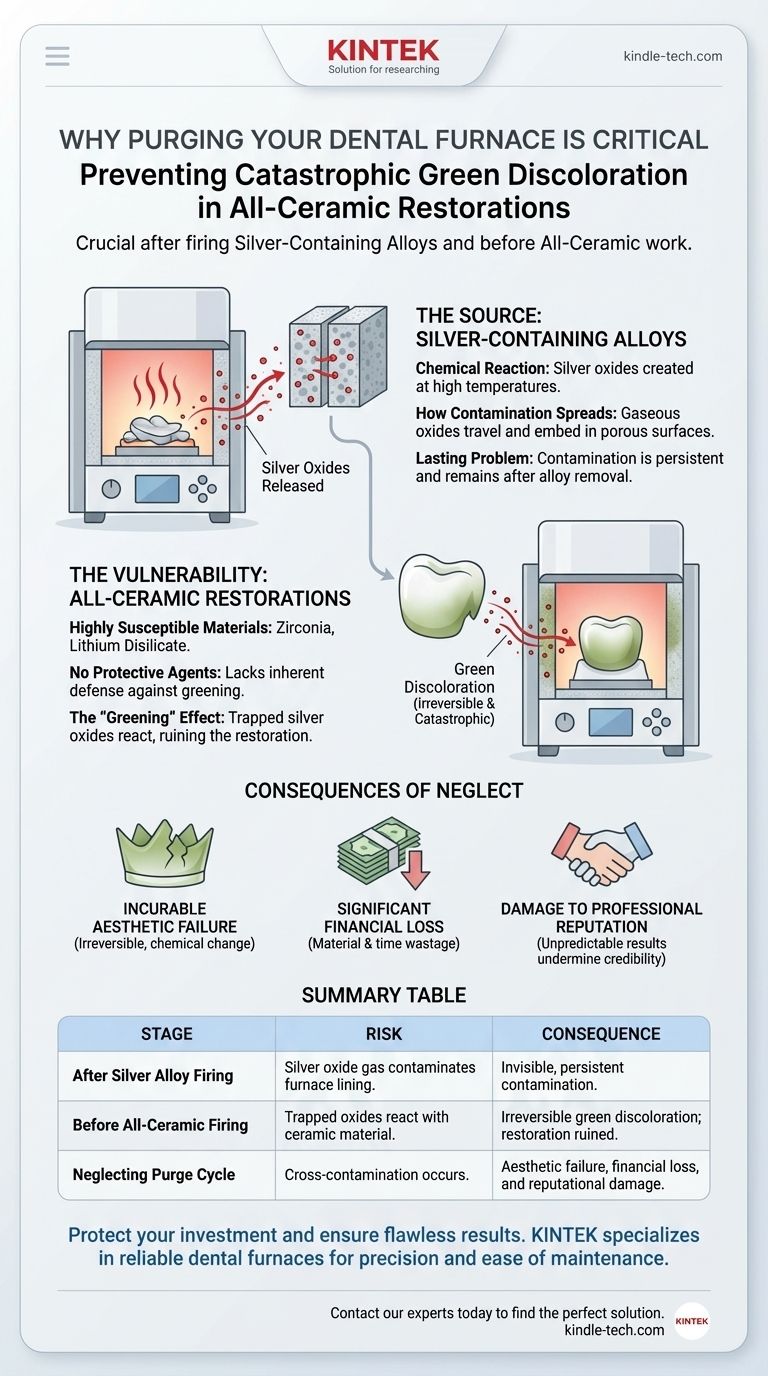

It is absolutely critical to purge a furnace after firing silver-containing alloys and before firing all-ceramic restorations to prevent catastrophic green discoloration. Silver alloys release silver oxides at high temperatures, which contaminate the furnace lining. These trapped oxides will then ruin any subsequent all-ceramic work by turning it green.

The core issue is cross-contamination at a microscopic level. A furnace that appears clean can harbor invisible silver oxide deposits from a previous firing, which will chemically react with and permanently discolor a subsequent, highly sensitive all-ceramic restoration.

The Source of Contamination: Silver-Containing Alloys

The Chemical Reaction

During the high-temperature firing cycle, the silver within a metal-ceramic alloy reacts with oxygen. This reaction creates volatile silver oxides.

How Contamination Spreads

These silver oxides are gaseous at firing temperatures. They travel throughout the furnace chamber and embed themselves into the porous surfaces of the furnace muffle or fire brick.

A Lasting Problem

This contamination is not temporary. The silver oxide particles remain trapped within the furnace lining long after the alloy has been removed, creating a persistent threat to any future firings.

The Vulnerability of All-Ceramic Restorations

Highly Susceptible Materials

Materials like zirconia and lithium disilicate are chemically susceptible to reacting with these silver oxides. Their composition makes them extremely sensitive to this specific type of contaminant.

Lack of Protective Agents

Most metal-ceramic materials are formulated with anti-greening properties to resist this effect. All-ceramic materials are not. They have no inherent defense against the chemical reaction that causes the discoloration.

The "Greening" Effect

When an all-ceramic restoration is fired in a contaminated furnace, the trapped silver oxides react with the ceramic. This results in an irreversible, catastrophic green discoloration, rendering the restoration aesthetically unacceptable and clinically useless.

Understanding the Consequences of Neglect

Incurable Aesthetic Failure

The greening effect is not a surface stain that can be polished off. It is a chemical change within the material itself, meaning the restoration cannot be salvaged.

Significant Financial Loss

Every failed restoration represents a complete loss of expensive materials and valuable technician time. The cost of a remake far exceeds the time required for a simple purge cycle.

Damage to Professional Reputation

Consistently producing restorations with unpredictable or poor aesthetics undermines the credibility of a dental laboratory or clinic. It introduces uncertainty into a process that demands precision and reliability.

Making the Right Choice for Your Workflow

Adopting a strict furnace hygiene protocol is the only way to ensure predictable and high-quality outcomes when working with these sensitive materials.

- If your primary focus is process efficiency: A dedicated furnace for all-ceramic restorations is the safest and most efficient long-term solution, eliminating the risk entirely.

- If you must use a single furnace: Make a full purge cycle a mandatory, non-negotiable step in your standard operating procedure immediately following any firing of a silver-containing alloy.

Proper furnace management is a foundational element of quality control in modern dental prosthetics.

Summary Table:

| Stage | Risk | Consequence |

|---|---|---|

| After Silver Alloy Firing | Silver oxide gas contaminates furnace lining. | Invisible, persistent contamination. |

| Before All-Ceramic Firing | Trapped oxides react with ceramic material. | Irreversible green discoloration; restoration ruined. |

| Neglecting Purge Cycle | Cross-contamination occurs. | Aesthetic failure, financial loss, and reputational damage. |

Protect your investment and ensure flawless results. Don't let cross-contamination compromise your dental restorations. KINTEK specializes in reliable, high-performance dental furnaces and consumables designed for precision and ease of maintenance. Contact our experts today to find the perfect furnace solution for your laboratory's workflow and eliminate the risk of greening for good.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is an economical method for purging a porcelain furnace muffle? A Simple, High-Heat Cycle for Cleaner Dental Restorations

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle

- Which is better ceramic or metal crown? Weighing Aesthetics vs. Durability for Your Smile

- What is a porcelain furnace used for in dentistry? Precision Crafting for Lifelike Dental Restorations

- What is the advantage of firing porcelain in a vacuum? Achieve Denser, Stronger, and More Aesthetic Dental Restorations

- What is the use of burnout oven? The Critical Step for Flawless Casting Results

- What is the average lifespan of a dental restoration? Maximize Your Investment with the Right Material

- What is dental ceramic used for? Restore Teeth with Aesthetic, Durable Crowns & Fillings