Avoiding collisions with a platinum disk electrode is paramount because platinum, despite its chemical inertness, is a very soft metal. Any physical impact can scratch, dent, or deform the electrode surface. This damage fundamentally alters its defined surface area and surface chemistry, which directly compromises the accuracy and reproducibility of your electrochemical measurements.

The physical integrity of your electrode is not just a matter of maintenance; it is the foundation of reliable electrochemical data. A pristine, well-defined surface ensures that your results are a true reflection of the chemical system, not an artifact of uncontrolled physical damage.

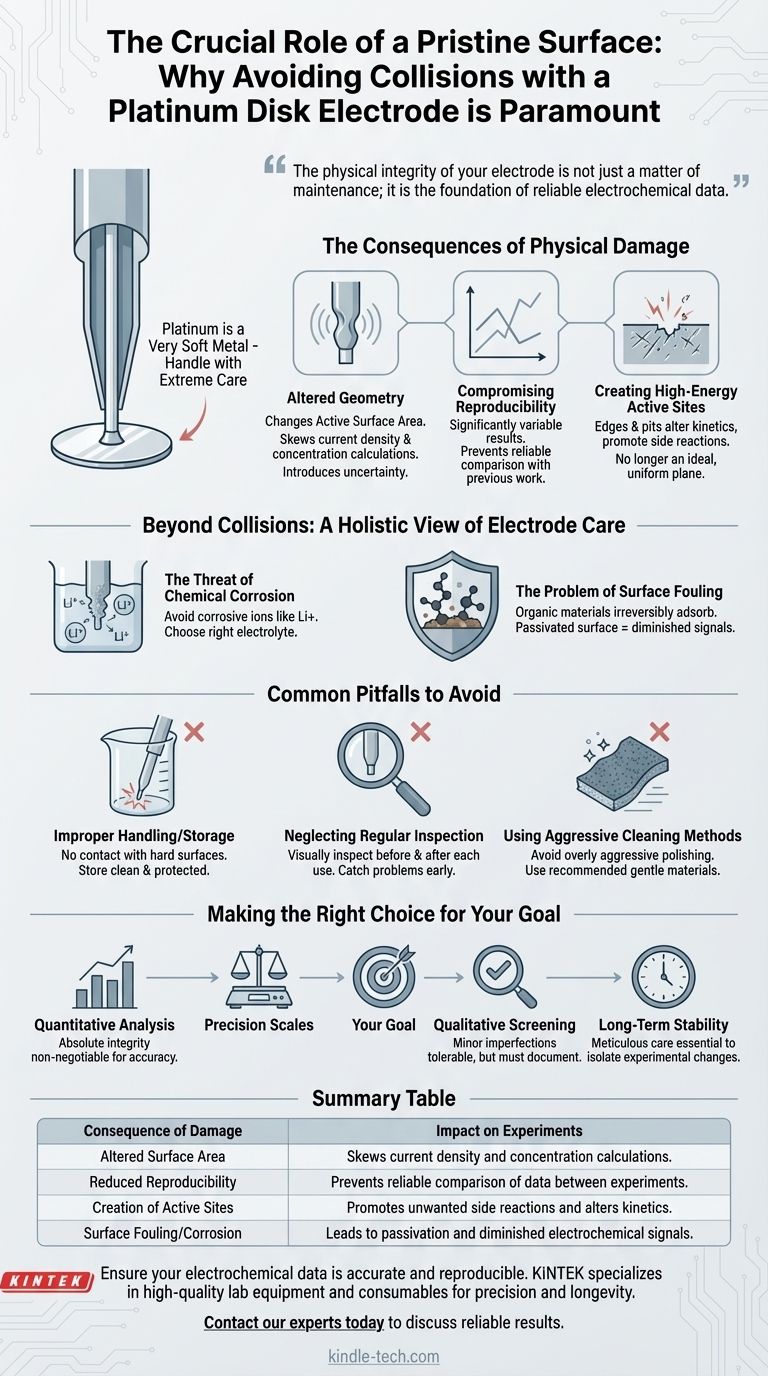

The Consequences of Physical Damage

A collision might seem minor, but its impact on electrochemical behavior can be significant. The core principles of electrochemistry rely on a well-characterized and consistent electrode surface.

Altering the Electrode's Geometry

The most immediate consequence of a scratch or dent is a change in the electrochemically active surface area. Calculations, such as current density, rely on a precise and known area. Physical damage introduces uncertainty, making it impossible to accurately normalize your measured current.

Compromising Data Reproducibility

Reproducibility is the cornerstone of scientific research. If your electrode surface is damaged between experiments, you are introducing a significant variable. Results obtained with a damaged electrode cannot be reliably compared to previous work or to data from other labs.

Creating High-Energy Active Sites

A smooth, polished surface behaves differently than a scratched one. The edges and pits created by a collision are high-energy sites that can alter reaction kinetics, promote unwanted side reactions, or change the way species adsorb to the surface. Your electrode no longer behaves as an ideal, uniform plane.

Beyond Collisions: A Holistic View of Electrode Care

While physical impact is a primary concern, maintaining a platinum electrode involves protecting it from all forms of degradation. The goal is to preserve a clean, chemically pure, and geometrically defined surface.

The Threat of Chemical Corrosion

Platinum is highly resistant to corrosion, but it is not completely immune. Choosing the right electrolyte and experimental conditions is crucial. Certain ions, most notably lithium ions (Li+), are known to be corrosive to platinum and their use should be strictly avoided.

The Problem of Surface Fouling

Contamination, or fouling, occurs when substances from the solution irreversibly adsorb onto the electrode. This is particularly common with organic materials. A fouled surface is a passivated surface, meaning it can no longer effectively transfer electrons with the species in your solution, leading to diminished or non-existent signals.

Common Pitfalls to Avoid

Protecting your investment and ensuring data quality comes down to a few consistent practices. Avoiding these common mistakes is critical.

Improper Handling and Storage

Never allow the electrode tip to make contact with hard surfaces, including the bottom or sides of your electrochemical cell. When not in use, it should be cleaned, dried, and stored in a dedicated, padded container where the tip is protected.

Neglecting Regular Inspection

Visually inspect the electrode surface before and after each use, preferably under magnification. Look for any new scratches, pits, or signs of discoloration. A consistent inspection routine allows you to catch problems early.

Using Aggressive Cleaning Methods

While polishing is necessary to maintain a mirror-like finish, overly aggressive mechanical cleaning can be as damaging as an accidental collision. Always use the recommended polishing materials and techniques to gently restore the surface without introducing new defects.

Making the Right Choice for Your Goal

To maintain the reliability of your electrochemical experiments, your handling protocol should reflect the sensitivity of your work.

- If your primary focus is quantitative analysis: Absolute surface integrity is non-negotiable, as any change in area directly skews current density and concentration calculations.

- If your primary focus is qualitative screening: While still critical, minor pre-existing imperfections may be tolerable, but you must document the electrode's condition to understand potential variations in results.

- If your primary focus is long-term stability studies: Meticulous care between runs is essential to ensure that observed changes are due to your experiment, not gradual electrode degradation.

Ultimately, treating your electrode with deliberate care is the first and most critical step toward producing data you can trust.

Summary Table:

| Consequence of Damage | Impact on Experiments |

|---|---|

| Altered Surface Area | Skews current density and concentration calculations. |

| Reduced Reproducibility | Prevents reliable comparison of data between experiments. |

| Creation of Active Sites | Promotes unwanted side reactions and alters kinetics. |

| Surface Fouling/Corrosion | Leads to passivation and diminished electrochemical signals. |

Ensure your electrochemical data is accurate and reproducible. Proper electrode care is fundamental, but so is using the right equipment. KINTEK specializes in high-quality lab equipment and consumables for all your laboratory needs. Whether you require reliable electrodes, cells, or accessories, our products are designed to support precision and longevity in your research.

Contact our experts today to discuss how we can help you achieve reliable and consistent results.

Visual Guide

Related Products

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- Why is platinum typically selected as the auxiliary electrode for electrochemical testing of oxazoline inhibitors?

- What is the function of a platinum electrode as an auxiliary electrode? Ensure Precise Nickel Coating Corrosion Testing

- Why is platinum a good counter electrode? For Superior Chemical Inertness and Electron Transfer

- What is the benefit of using a platinized platinum wire as a counter electrode? Optimize Operando Study Precision

- What are the advantages of using a Platinum (Pt) electrode for zirconium testing? Ensure High-Precision Data Integrity