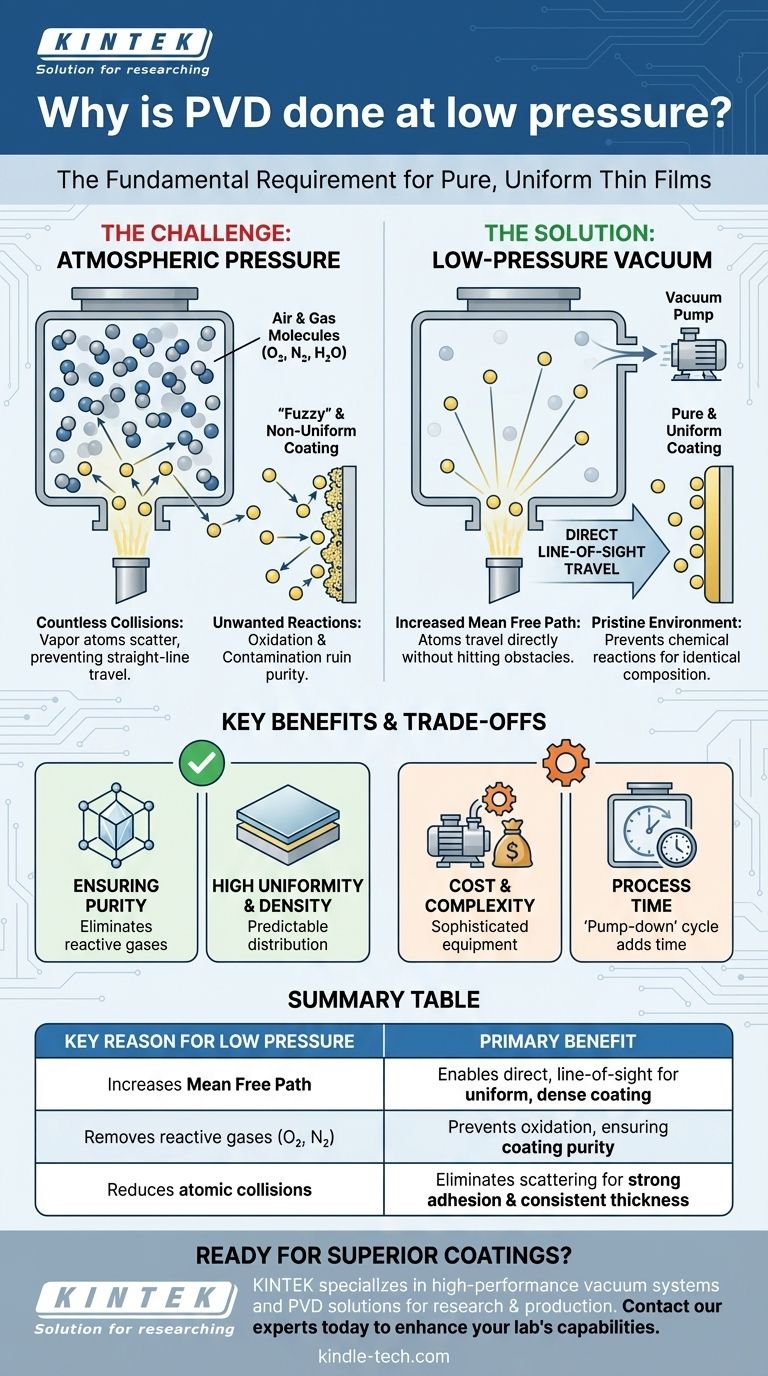

In Physical Vapor Deposition (PVD), a low-pressure vacuum environment is not just a preference; it is a fundamental requirement for success. This process is performed in a vacuum primarily to remove air and other gas molecules that would otherwise interfere with the deposition. By creating a near-empty space, we ensure the vaporized coating material can travel unimpeded from its source to the substrate, resulting in a pure, uniform, and high-quality thin film.

The core reason for using low pressure in PVD is to gain absolute control over the path and purity of the coating material. Removing atmospheric gases prevents random collisions and unwanted chemical reactions, which are the two primary factors that would otherwise ruin the final film.

The Role of a Vacuum in Vapor Transport

Physical Vapor Deposition is a line-of-sight process where a material is vaporized, travels through a chamber, and condenses onto a substrate. The low-pressure environment is critical for the "travel" phase of this journey.

Eliminating Obstacles: The "Mean Free Path"

At atmospheric pressure, a chamber is filled with countless air and water molecules. A vaporized atom of coating material would collide with these molecules billions of times per second.

This constant scattering deflects the atoms, preventing them from traveling in a straight line. The result, as noted in poor vacuum conditions, is a non-uniform, low-adhesion, and "fuzzy" deposition rather than a smooth film.

By pumping the chamber down to a very low pressure, we drastically reduce the number of gas molecules. This increases the mean free path—the average distance a vapor atom can travel before hitting something else. In a high vacuum, the mean free path can become longer than the chamber itself, allowing atoms to fly directly to the substrate without collision.

Preventing Unwanted Chemical Reactions

The source material in PVD is heated to a high-energy vapor state. If exposed to atmospheric gases like oxygen and nitrogen, this hot vapor would react instantly.

This process, called oxidation or nitridation, contaminates the film. Instead of depositing a pure metal, for example, you would deposit a brittle and inconsistent metal oxide. A vacuum removes these reactive gases, ensuring the film's chemical composition is identical to the source material.

How Low Pressure Dictates Film Quality

The controlled environment created by a vacuum directly translates to the final characteristics of the coating. The two primary benefits are purity and uniformity.

Ensuring Coating Purity

By eliminating reactive atmospheric gases, a vacuum ensures that the only material condensing on the substrate is the desired source material. This guarantees the chemical and mechanical properties of the thin film are exactly what was intended.

Achieving High Uniformity and Density

The straight, line-of-sight travel enabled by a long mean free path is the key to a uniform coating. It allows for predictable and even distribution of the vapor flux across the substrate surface.

Without this direct path, the deposition would be chaotic and random, leading to a film with inconsistent thickness, poor density, and weak adhesion.

Understanding the Trade-offs

While essential, creating and maintaining a vacuum introduces its own set of technical and economic considerations.

The Cost and Complexity of a Vacuum

Achieving the low pressures required for high-quality PVD necessitates sophisticated and expensive equipment. High-vacuum pumps, robust steel chambers, and precise gauges add significant cost and complexity to the process.

Process Time and Throughput

Evacuating a chamber to the target pressure—a step known as the "pump-down"—takes time. This can become a bottleneck in high-volume manufacturing, as it adds to the overall cycle time for each batch of coated parts. The level of vacuum required is often a balance between ideal film quality and practical production speed.

Making the Right Choice for Your Goal

Understanding why a vacuum is used allows you to control the process for specific outcomes. The level of vacuum is not arbitrary; it is a critical parameter tuned to achieve a desired result.

- If your primary focus is material purity: A high vacuum is non-negotiable to prevent contamination from atmospheric gases like oxygen and nitrogen.

- If your primary focus is film uniformity and density: A low pressure is essential to maximize the mean free path, ensuring a direct line-of-sight for vapor deposition.

- If your primary focus is process efficiency: The specific level of vacuum becomes a critical trade-off between the required film quality and the cost and time associated with the pump-down cycle.

Ultimately, mastering the vacuum environment is fundamental to mastering the PVD process itself.

Summary Table:

| Key Reason for Low Pressure | Primary Benefit |

|---|---|

| Increases the Mean Free Path of vapor atoms | Enables direct, line-of-sight travel for a uniform, dense coating |

| Removes reactive gases (O₂, N₂) | Prevents oxidation and nitridation, ensuring coating purity |

| Reduces atomic collisions with air molecules | Eliminates scattering for strong adhesion and consistent thickness |

Ready to achieve superior thin-film coatings with precision PVD?

KINTEK specializes in high-performance lab equipment, including vacuum systems and PVD solutions tailored for research and production. Our expertise ensures you get the right setup for pure, uniform, and high-quality results.

Contact our experts today to discuss your specific application and how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes