Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Thermal Equipment

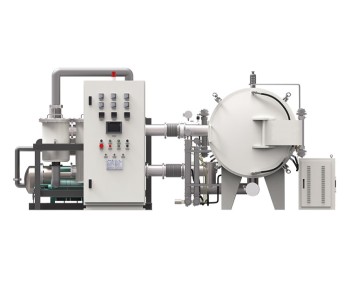

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Thermal Equipment

Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

Item Number: KT-DS10

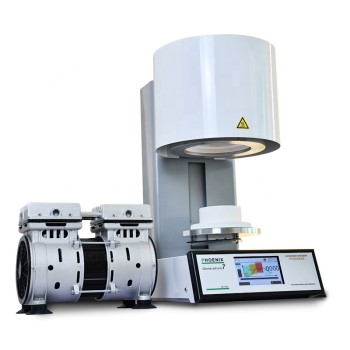

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Item Number: KT-DP10

Vacuum Dental Porcelain Sintering Furnace

Item Number: KT-DV10

1400℃ Muffle Oven Furnace for Laboratory

Item Number: KT-14M

1200℃ Muffle Furnace Oven for Laboratory

Item Number: KT-12M

1700℃ Muffle Oven Furnace for Laboratory

Item Number: KT-17M

1800℃ Muffle Oven Furnace for Laboratory

Item Number: KT-18M

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

Item Number: KT-SH

KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

Item Number: KT-VA12

Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

Item Number: KT-VA06

KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

Item Number: KT-VA07

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Item Number: KT-VA08

304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

Item Number: KT-VA11

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Physics of Perfection: Why Hot Pressing is an Investment in Material Certainty

Hot press forming isn't just about shape; it's a strategic process for creating dense, stable, and flawless materials by mastering heat and pressure.

Gravity, Geometry, and Heat: The Engineering Behind Tube Furnace Orientation

Discover how tube furnace orientation—horizontal, vertical, or rotary—dictates thermal thermodynamics, sample integrity, and experimental success.

The Engineering of Nothingness: Why Perfection Requires a Vacuum

Vacuum furnaces trade atmospheric chaos for controlled purity. Explore how heat treating, brazing, and sintering in a void creates superior metallurgy.

The Engineer's Gambit: Why Molybdenum Defines the Modern Vacuum Furnace

Discover why molybdenum is key to vacuum furnace purity and how hot zone design dictates temperature uniformity in critical manufacturing processes.

The Architecture of Emptiness: How Vacuum Tube Furnaces Defy Entropy

Discover the precise engineering behind vacuum tube furnaces. Learn how thermal isolation and high-vacuum systems create the ultimate environment for material purity.

The Unseen Discipline: Mastering the Alumina Furnace Tube

Learn how proactive maintenance, not just reactive cleaning, prevents thermal shock and contamination to ensure the integrity of your lab results.

The Geometry of Heat: Navigating the Choice Between Tube and Box Furnaces

Discover the systemic difference between continuous tube furnaces and static box furnaces. Learn how workflow dictates your hardware choice.

The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

Discover why the absence of air is critical for advanced heat treatment. Learn how vacuum furnaces prevent oxidation and ensure material integrity.

Beyond the Spec Sheet: The Hidden Physics of a Tube Furnace's True Limit

A furnace's maximum temperature is a deceptive metric. Its true limit is defined by the weakest component in a complex thermal system.

The Silent Engine: Engineering the Perfect Thermal Environment

Choosing the right vacuum furnace heating element is a balance of physics and economics. Discover how Molybdenum, Graphite, and Tungsten define process purity.

The Architecture of Heat: Why Precision is the Only Variable That Matters

A tube furnace is more than an oven; it is a system of isolation and control. Explore the engineering behind thermal uniformity and atmosphere management.

Beyond Temperature: The Art of Atmospheric Control in a Tube Furnace

A tube furnace's power isn't just its heat, but its precise control over the internal atmosphere—a key factor for advanced materials science.

The Silent Efficiency of the Void: Mastering Heat Transfer in Vacuum Furnaces

Discover why vacuum furnaces reject convection for radiation. A deep dive into the physics of purity, line-of-sight heating, and precision control.

The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

Vacuum furnaces offer more than just heat; they offer total environmental control. Explore the physics of radiative heating, outgassing, and why the void is essential for purity.

The Architecture of Silence: Why Material Choice Defines Electrochemical Truth

Explore how High Borosilicate Glass, PTFE, and POM create the perfect chemically inert environment for accurate electrochemical testing.

The Anatomy of Purpose: Why a Tube Furnace is More Than a Box of Heat

A tube furnace isn't a commodity; its design is a direct reflection of your process. Learn how temperature, atmosphere, and throughput forge its form.

The Symphony of Silence: Engineering Heat in a Vacuum

Discover the engineering behind vacuum furnaces. Learn how resistance heating, hot zones, and cooling systems work together to master material properties.

The Furnace Dilemma: Choosing Between Precision and Scale in Thermal Processing

Choosing a vacuum furnace isn't just about specs. It's a strategic trade-off between the precision of a tube and the scale of a chamber.

The Art of Nothing: Why Precision in Vacuum Pressure Defines Material Success

Vacuum pressure is not a binary switch; it's a spectrum of purity. Discover how controlling the void protects materials from the chaos of oxidation and contamination.

Mastering the Void: How Vacuum Furnaces Redefine Material Purity

Vacuum furnaces aren't just for heating; they create a controlled void to eliminate atmospheric variables, enabling the creation of high-purity materials.