Overview of Hot Isostatic Pressing

Definition and purpose of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a manufacturing process that involves the simultaneous application of high temperature and pressure to metals and other materials. The purpose of HIP is to reduce the porosity of metals and increase the density of ceramic materials. This process improves the mechanical properties and workability of the materials.

Role of HIP in reducing porosity of metals and increasing density of ceramic materials

In powder metallurgy, HIP allows for the compression of metal powder at high temperatures and pressures. Through a combination of deformation, creep, and diffusion, HIP creates a product with a homogenous annealed microstructure and minimal impurities. This results in a compact solid with reduced porosity and increased density.

HIP is a key part of through-processing, from alloy design to component manufacture, and is particularly essential for aerospace components. The HIP unit has a 150mm diameter x 300mm long hot zone, making it suitable for scaling up samples.

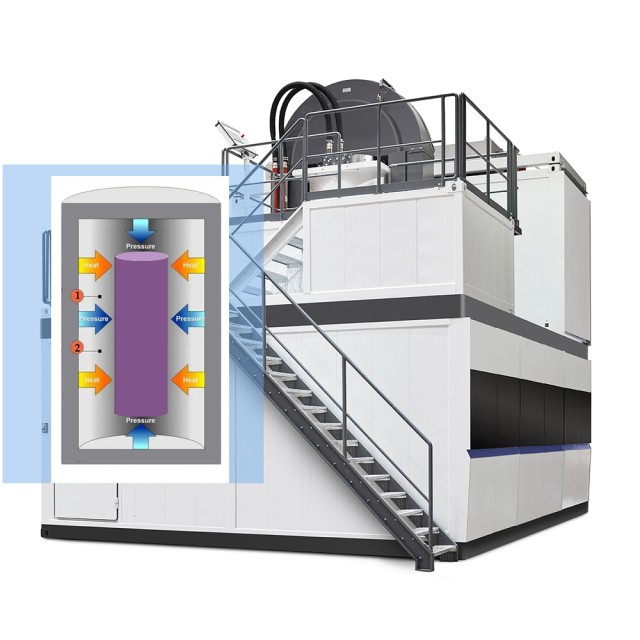

Hot Isostatic Pressing (HIP) is the simultaneous application of high temperature and pressure to metals and other materials for a specified amount of time. In the HIP unit, a high temperature furnace is enclosed in a pressure vessel. The temperature, pressure, and process time are precisely controlled to achieve optimum material properties.

In the HIP process, parts are heated in an inert gas, usually argon, which applies "isostatic" pressure uniformly in all directions. This pressure causes the material to become "plastic," allowing voids to collapse under the differential pressure. The surfaces of the voids diffusion bond together, effectively eliminating defects and achieving near theoretical density. This process also improves the mechanical properties of the parts, such as investment castings.

Hot isostatic pressing (HIP) is a manufacturing process that utilizes elevated temperature and isostatic gas pressure to eliminate porosity and increase density in metals, ceramics, polymers, and composite materials. This improves the material's mechanical properties and potentially workability. Primary applications of HIP include the elimination of microshrinkage in castings, consolidation of powders, diffusion bonding, and fabrication of metal matrix composites.

In addition, HIP is used as part of a sintering process in powder metallurgy, for pressure-assisted brazing, and for the fabrication of metal matrix composites.

Overall, Hot Isostatic Pressing (HIP) is a versatile and effective manufacturing technique for reducing porosity in metals and increasing the density of ceramic materials. It plays a crucial role in improving the mechanical properties and workability of various materials, making it essential for industries such as aerospace and powder metallurgy.

Applications of Hot Isostatic Pressing

Use of HIP in powder metallurgy

In powder metallurgy, Hot Isostatic Pressing (HIP) is used to compress a volume of metal powder at high temperatures and pressures. This process combines deformation, creep, and diffusion to create a product with a homogeneous annealed microstructure and minimal impurities in the materials. HIP is essential for through-processing and manufacturing aerospace components.

Process of creating a product with homogenous annealed microstructure using HIP

Hot Isostatic Pressing is a manufacturing process that utilizes elevated temperature and isostatic gas pressure to eliminate porosity and increase density in metals, ceramics, polymers, and composite materials. This process improves the mechanical properties and workability of the materials. HIP can eliminate microshrinkage in castings, consolidate powders, facilitate diffusion bonding, and fabricate metal matrix composites.

Importance of HIP in through-processing and aerospace components manufacture

Hot Isostatic Pressing plays a crucial role in through-processing, from alloy design to component manufacture. It is an essential process for manufacturing aerospace components. The HIP unit has a 150mm diameter x 300mm long hot zone, making it ideal for scaling up samples. HIP technology is also used in various industries such as ceramics, porous materials, material bonding, and high-end graphite manufacturing.

Hot Isostatic Pressing has become a regular production process over the last 50 years. The future of this technology looks promising as there is a growing demand for improved material properties, the use of powder materials, and the desire to produce net or near net shape parts.

Hot Isostatic Pressing (HIP) has been used for decades to consolidate metal powders, eliminate porosity in sintered parts, produce metal-clad parts, and improve the quality of critical components produced by powder-based Additive Manufacturing. HIP is an essential process for improving the quality and performance of components in the aerospace industry and other sectors.

Description of Hot Isostatic Pressing

Explanation of the HIP process

Hot Isostatic Pressing (HIP) is a manufacturing process that utilizes high temperature and isostatic gas pressure to eliminate porosity and increase the density of metals, ceramics, polymers, and composite materials. This process improves the mechanical properties and workability of the materials. HIP involves the simultaneous application of heat and high pressure to the materials, causing their physical properties to change.

Details about the hot zone in the HIP

The HIP unit consists of a high temperature furnace enclosed in a pressure vessel. The hot zone in the HIP has a diameter of 150mm and a length of 300mm, making it suitable for scaling up samples. In the hot zone, materials are heated in an inert gas, typically argon, which applies isostatic pressure uniformly in all directions. This pressure causes the material to become plastic, allowing voids to collapse under the differential pressure. The surfaces of the voids diffusion bond together, effectively eliminating defects and achieving near theoretical density. The HIP process is essential for through-processing in industries such as aerospace, where it is used for manufacturing components.

Specifications of Hot Isostatic Pressing Equipment

Working Pressure

The hot isostatic pressing equipment operates at a working pressure of 45,000 PSI (310 MPa). This high pressure is necessary to subject the metal or ceramic products to equal pressure in all directions, allowing for effective sintering and densification.

Control System

The equipment is equipped with a fully automatic control system, which provides an easy-to-use operator interface. The control system allows for precise control over the temperature ramp-up, pressure, and duration of the process.

Thermocouple Type

The hot isostatic pressing equipment uses four type C thermocouples (Tungsten/Rhenium) for temperature measurement. These thermocouples are attached outside the pressure vessel to accurately monitor the temperature during the process.

Vessel Interior Length

The interior length of the pressure vessel is 24 inches (610mm). This provides ample space to accommodate the workpiece (tooling and components) to be subjected to the hot isostatic pressing process.

Graphite Furnace and its Usage Limit

The equipment includes a graphite furnace that can be used at temperatures up to 2000°C. The graphite furnace provides the necessary heat required for the hot isostatic pressing process.

Heating Rate

The standard furnace rate of the equipment allows for a heating rate of up to 25°C per minute. This ensures efficient and controlled heating of the workpiece during the process.

Cooling Rate

The hot isostatic pressing equipment is capable of achieving a cooling rate of up to 40°C per minute. This rapid cooling allows for effective quenching and solidification of the material.

Maximum Sample Size

The equipment can accommodate a maximum sample size of 60mm in diameter and 300mm in height. This size limitation ensures that a wide range of parts and components can be processed using the hot isostatic pressing technique.

Hot isostatic pressing (HIP) is a highly promising technology that has been ranked among the top three technologies and processes by the North American Heat Treatment Association. It finds applications in various industries, including automotive, aerospace, military, heavy equipment, industrial machinery, marine, oil and gas, and medical.

The hot isostatic pressing equipment consists of a high-pressure vessel, heating furnace, compressor, vacuum pump, storage tank, cooling system, and computer control system. The high-pressure vessel is the key component of the equipment, responsible for subjecting the parts to equal pressure in all directions.

The hot isostatic pressing process involves loading the components into the machine's chamber. The chamber can be loaded from either the top or the bottom, depending on the machine. Once loaded, the process is controlled by computers, which program the equipment to achieve the desired results. The temperature ramp-up, pressure, and duration of the process can be adjusted by the user.

Hot isostatic pressing equipment comes in various sizes, ranging from compact machines for small parts to industrial-sized equipment for large industrial parts. The equipment utilizes inert gas, typically argon, to apply equal force to the parts for densification. The gas pressure is achieved through a compressor and/or thermal expansion.

In comparison to other techniques like die pressing, hot isostatic pressing offers advantages such as improved temperature field uniformity, energy efficiency, and the ability to prepare large diameter materials. The investment required for hot isostatic pressing equipment is relatively small, making it a cost-effective option for many applications.

Hot isostatic pressing equipment is a versatile solution for achieving sintering and densification in metal and ceramic products. Its specifications, including the working pressure, control system, thermocouple type, vessel interior length, graphite furnace usage limit, heating rate, cooling rate, and maximum sample size, ensure precise and efficient processing of parts and components.

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Warm Isostatic Press for Solid State Battery Research

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- What is Isostatic Pressing Machine

- Comprehensive Guide to Isostatic Pressing:Processes, and Features

- Isostatic Pressing Technology: Principles, Classification, and Applications

- Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

- Understanding the Isostatic Pressing Process and its Types