Imagine spending weeks synthesizing a novel metal alloy powder, meticulously controlling every variable. The final step is a critical high-temperature annealing process to optimize its crystal structure. You place your sample in a standard furnace, set the temperature, and wait. But when you open the door, your pristine, metallic-grey powder has become a useless, oxidized black clump. Your project is set back, and weeks of work are lost. The culprit wasn't your material or your process; it was the very air inside the furnace.

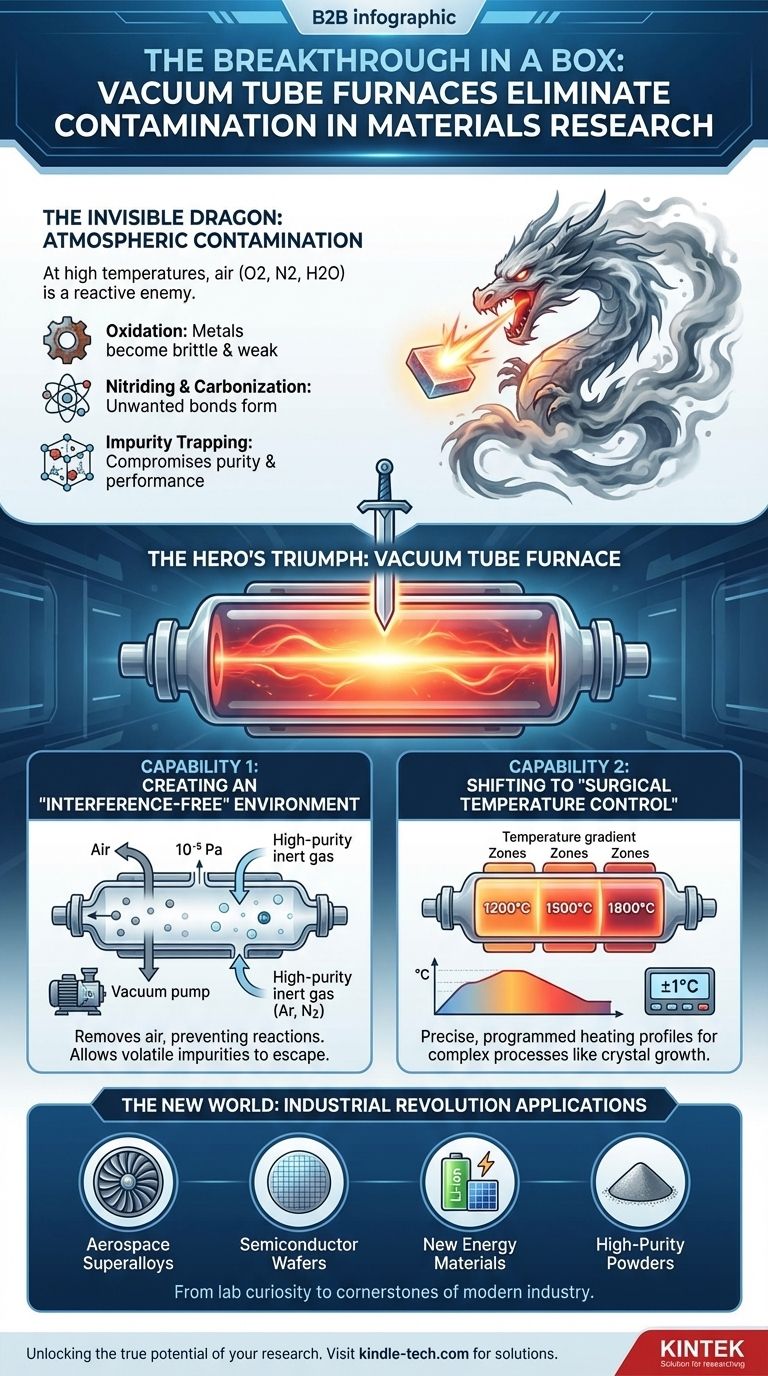

The Invisible Dragon: Why Air is the Enemy of Advanced Materials

For researchers in materials science, semiconductors, and new energy, atmospheric contamination is a persistent, destructive dragon. At the high temperatures required for sintering, annealing, or crystal growth, the seemingly harmless air around us becomes a highly reactive agent.

Oxygen, nitrogen, and water vapor aggressively attack sensitive materials. This isn't just a minor inconvenience; it's a fundamental barrier that can render experiments useless and cap the performance of new technologies.

- Oxidation: Metals lose their desired properties, turning brittle and weak.

- Nitriding & Carbonization: Unwanted chemical bonds form, altering the material's electrical and mechanical characteristics.

- Impurity Trapping: Volatile impurities cannot escape, compromising the final purity of the material and preventing it from reaching theoretical performance limits.

This "dragon" of contamination has historically made it incredibly difficult to produce materials with the near-perfect purity and structural integrity demanded by today's most advanced applications.

The Hero's Triumph: A New Era of Material Purity and Performance

Today, scientists and engineers are consistently achieving what was once impossible. They are routinely creating materials that conquer the contamination dragon, leading to tangible technological leaps:

- In Materials Science: They synthesize high-purity metal powders exceeding 99.99% purity, as impurities are vaporized and removed, not trapped. Specialty ceramics are sintered into dense, flawless forms, free from the porosity that causes weakness.

- In New Energy: They calcine cathode materials for lithium-ion batteries (like LiNiCoMnO₂) in a protected environment, ensuring the crystal structure remains stable. The result is higher battery capacity and a significantly longer cycle life.

- In Semiconductors: They anneal silicon wafers to repair lattice defects without introducing new ones from oxidation, a critical step for manufacturing high-performance chips. They can also precisely "activate" implanted ions to form circuits, a process that would fail in a reactive atmosphere.

These breakthroughs are not the result of a single discovery but of a fundamental shift in how researchers control the experimental environment.

How They Did It: The Magic Sword That Slays the Dragon

This new level of material control was made possible by a critical tool: the Vacuum Tube Furnace. It provides the hero—the researcher—with a "magic sword" capable of creating a perfect, isolated world where materials can transform exactly as intended.

A modern vacuum tube furnace attacks the contamination dragon on two fronts:

Capability 1: Creating an "Interference-Free" Environment

The core function of the furnace is to eliminate the atmosphere entirely. By using a vacuum pump, it can remove the air from the sealed furnace tube to a level as low as 10⁻⁵ Pa—an environment cleaner than outer space. Alternatively, it can be backfilled with a high-purity inert gas like argon or nitrogen. This creates an isolated reaction space that completely prevents oxidation, nitriding, and other unwanted reactions, allowing volatile impurities to escape freely.

Capability 2: Shifting from "Heating" to "Surgical Temperature Control"

Slaying the dragon isn't just about removing the air; it's also about applying heat with absolute precision. Unlike conventional ovens, a vacuum tube furnace uses an intelligent, multi-segment control system to manage temperature with an accuracy of ±1°C, even up to 1800°C or higher. This enables complex, programmed heating profiles—like gradient temperature control, where different zones of the tube are held at different temperatures. This precision is essential for delicate processes like crystal growth and eliminating internal stress in alloys without creating new defects.

The New World: From Lab Bench to Industrial Revolution

By giving researchers a weapon to defeat environmental contamination, the vacuum tube furnace is unlocking a new world of commercial applications. The ultra-pure, high-performance materials forged in these furnaces are no longer just laboratory curiosities; they are the cornerstones of modern industry.

- Aerospace: High-temperature superalloys for jet engine blades are heat-treated in a vacuum, ensuring they maintain their strength under extreme conditions without oxidizing.

- Semiconductors: The flawless chip wafers annealed in these furnaces are powering the AI and data revolutions.

- New Energy: More efficient photovoltaic cells and longer-lasting electric vehicle batteries are direct results of the superior materials prepared under these controlled conditions.

What was once a battle fought on every lab bench is now a solved problem, allowing innovators to focus on the next frontier of discovery.

The journey from a promising material concept to a revolutionary product is fraught with its own unique challenges. The vacuum tube furnace is a powerful tool, but achieving your specific goals—whether it's higher battery capacity, flawless wafer annealing, or a new superalloy—requires the right configuration and expertise. If you're ready to eliminate environmental variables and unlock the true potential of your research, our specialists are here to help you select and configure the precise solution for your application.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- Why Your Furnace Components Keep Failing—And the Material Science Fix

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- Beyond the Spec Sheet: The Hidden Physics of a Tube Furnace's True Limit

- Installation of Tube Furnace Fitting Tee

- Your Tube Furnace Is Not the Problem—Your Choice of It Is