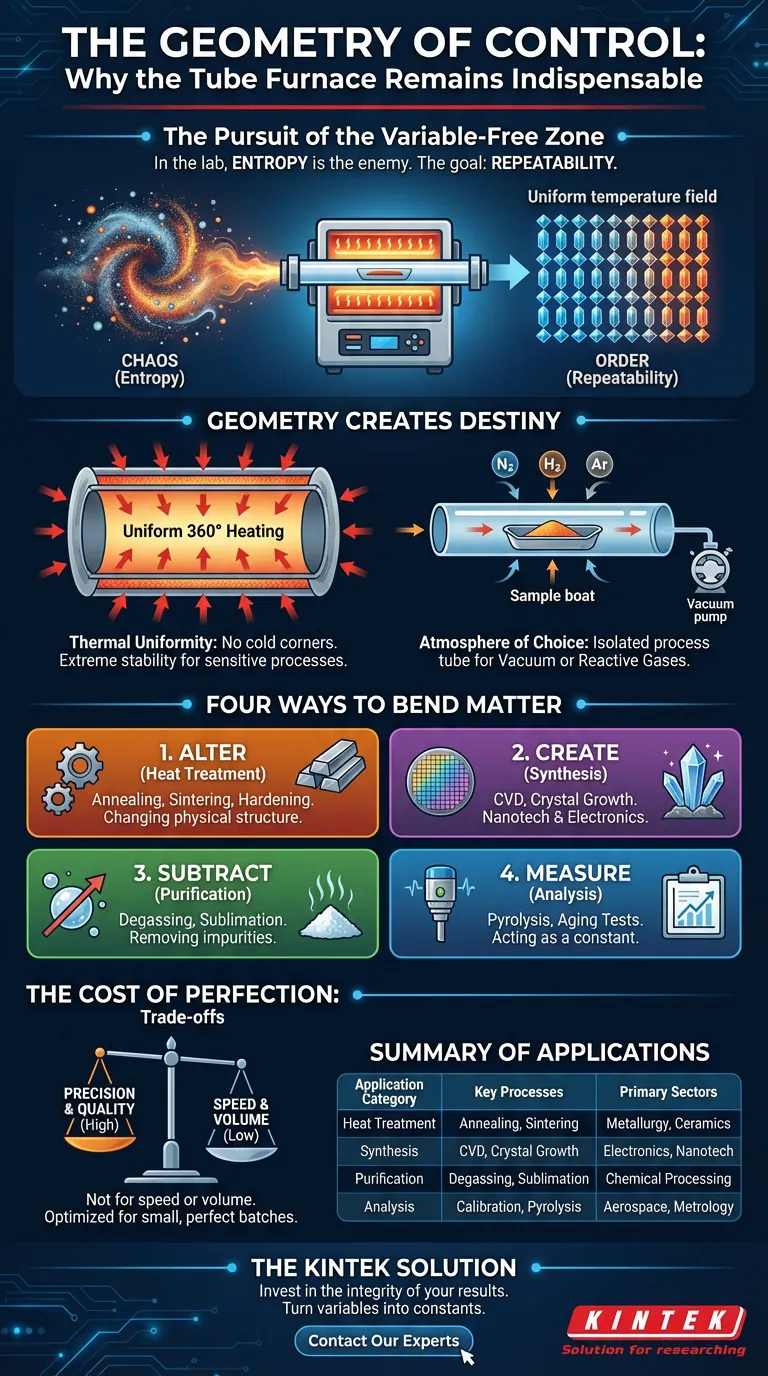

The Pursuit of the Variable-Free Zone

In the laboratory, entropy is the enemy.

The struggle of materials science is not usually about discovering a new reaction. It is about repeatability. Can you make the crystal grow exactly the same way twice? Can you sinter the ceramic without a single microscopic crack caused by an uneven thermal gradient?

This is where the tube furnace distinguishes itself. It is not simply an oven; it is a machine designed to impose strict order on a chaotic environment. By understanding the engineering behind it, we see why it remains the backbone of advanced research, from basic metallurgy to semiconductor fabrication.

The tube furnace offers a specific kind of romance to the engineer: the ability to isolate a small piece of the universe and control every parameter within it.

Geometry Creates Destiny

The versatility of the tube furnace is not an accident. It is a direct result of its cylindrical geometry.

When you heat a box, corners create cold spots. Air currents create turbulence. But a tube is different.

Thermal Uniformity

In a cylindrical heating chamber, the heat radiates inward from all 360 degrees. There are no corners to trap cooler air. This creates a zone of extreme thermal uniformity.

For processes like thermocouple calibration or crystal growth, even a deviation of a few degrees can render the data useless. The tube furnace ensures that the temperature you set is the temperature the sample actually experiences.

The Atmosphere of Choice

The second defining feature is isolation. A process tube—typically quartz or alumina—physically separates the sample from the heating elements. This separation allows for two critical capabilities:

- Vacuum Environments: You can remove air entirely to prevent oxidation.

- Reactive Atmospheres: You can introduce specific gases (Hydrogen, Nitrogen, Argon) to facilitate chemical reactions that would be impossible in open air.

Four Ways to Bend Matter

Because it controls both heat and atmosphere, the tube furnace becomes a multipurpose tool. We can categorize its utility into four distinct "intents."

1. The Intent to Alter (Heat Treatment)

Here, the material remains chemically the same, but its physical structure changes.

- Annealing: Softening metals to fix the brittleness caused by working them.

- Sintering: Fusing powders into solid ceramics without melting them effectively.

- Hardening: Rearranging the crystalline lattice to increase durability.

2. The Intent to Create (Synthesis)

This is the domain of nanotechnology and electronics.

- Chemical Vapor Deposition (CVD): Gases are reacted to deposit thin films on a substrate (crucial for semiconductors).

- Crystal Growth: Growing single, perfect crystals slowly over time.

3. The Intent to Subtract (Purification)

Sometimes, value comes from what you remove.

- Degassing: Using vacuum pressure and heat to pull trapped gases out of a material.

- Sublimation: Turning solids directly to gas to leave impurities behind.

4. The Intent to Measure (Analysis)

Because the furnace is so stable, it acts as a "constant" in analytical equations.

- Pyrolysis: Breaking compounds down to see what they are made of.

- Aging Tests: Simulating years of wear in a matter of hours.

The Cost of Perfection

In engineering, there are no solutions, only trade-offs. The tube furnace is no exception.

The very features that make it precise also impose limitations.

It is not built for speed. The insulation and thermal mass required to hold a stable temperature mean these furnaces heat up and cool down slowly. They are poor tools for rapid thermal cycling.

It is not built for volume. Tube furnaces are batch processors. You are limited by the diameter and length of the tube. If you need to treat thousands of automotive gears per hour, you use a conveyor belt furnace. If you need to treat ten grams of experimental alloy perfectly, you use a tube furnace.

Summary of Applications

The following table maps the capability to the industry sector:

| Application Category | Key Processes | Primary Sectors |

|---|---|---|

| Heat Treatment | Annealing, Sintering, Tempering | Metallurgy, Ceramics |

| Synthesis | CVD, Crystal Growth | Electronics, Nanotech |

| Purification | Degassing, Sublimation | Chemical Processing |

| Analysis | Calibration, Pyrolysis | Aerospace, Metrology |

The KINTEK Solution

Choosing a tube furnace is a decision to prioritize quality over quantity, and precision over speed.

At KINTEK, we understand that you aren't just buying equipment; you are investing in the integrity of your results. Whether you are growing graphene layers or calibrating aerospace sensors, our tube furnaces are engineered to provide the uniform heating and atmospheric control your research demands.

We provide the "certainty machine" your lab needs to turn variables into constants.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Your Tube Furnace Is Not the Problem—Your Choice of It Is

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit