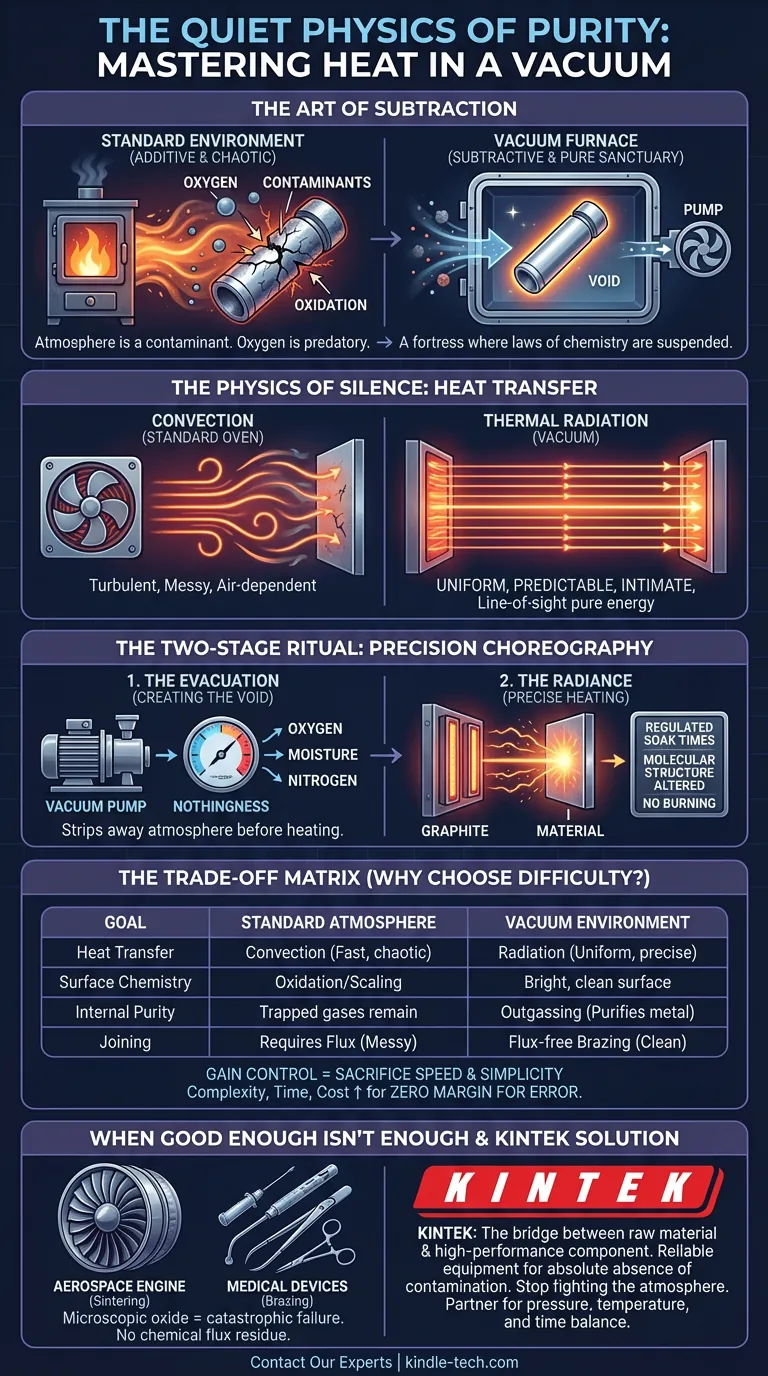

The Art of Subtraction

We intuitively understand heating as an additive process. You add fire. You add electricity. You add energy to a system to change it.

But in advanced materials science, the most critical step is often subtractive. Before you can add heat, you must remove the chaos.

In a standard environment, the atmosphere is a contaminant. Oxygen is chemically aggressive. At high temperatures, it becomes predatory. It attacks titanium. It corrupts stainless steel. It forms oxides that act as microscopic stress fractures waiting to happen.

The vacuum furnace is not merely an oven. It is a fortress.

Its primary function is not to make things hot, but to create a sanctuary where the laws of chemistry are temporarily suspended. By evacuating the air, we stop the natural world from interfering with our engineering.

The Physics of Silence

When you remove the atmosphere, you change how energy moves.

In a conventional oven, heat travels via convection. Hot air circulates, tumbling over the material like a warm wind. It is effective, but it is messy.

In a vacuum, there is no air to move the heat. Convection is impossible.

Instead, the system relies on thermal radiation. Energy travels as light waves directly from the heating elements to the material. It is a line-of-sight transfer of pure energy.

This shift creates a specific kind of engineer’s romance:

- Uniformity: The heat is not blown around; it is radiated evenly.

- Predictability: Without air currents, the variables drop.

- Intimacy: The material interacts only with energy, not with gas.

The Two-Stage Ritual

Every cycle in a vacuum furnace follows a script designed to ensure repeatability. It is a precise choreography of pressure and temperature.

1. The Evacuation

Before a single degree of heat is added, the system creates the void.

Pumps engage. Valves open and close. The goal is to drag the internal pressure down far below atmospheric levels. This strips away oxygen, moisture, and nitrogen.

The chamber becomes a "nothingness." Only then is it safe to proceed.

2. The Radiance

Once the vacuum is established, the heating elements—often graphite or refractory metals—begin to glow.

Because there is no air to buffer the heat, the control system must be incredibly precise. It regulates the "soak times" (how long the material sits at a specific temperature) to alter the molecular structure of the metal without burning the surface.

Why We Choose Difficulty

If vacuum furnaces are so effective, why don't we use them for everything?

Because perfection is expensive.

There is a psychological trade-off in engineering: To gain control, you must sacrifice speed and simplicity.

- Complexity: These are not simple boxes. They require high-performance pumps and leak-proof seals.

- Time: Pumping down a chamber takes time. Cooling a material in a vacuum—where there is no air to carry the heat away—is a slow process, often requiring a backfill of inert gas like argon to speed it up.

- Cost: The capital investment is significantly higher than atmospheric furnaces.

However, for specific outcomes, there is no alternative.

The Trade-off Matrix

| Goal | Standard Atmosphere | Vacuum Environment |

|---|---|---|

| Heat Transfer | Convection (Fast, chaotic) | Radiation (Uniform, precise) |

| Surface Chemistry | Oxidation/Scaling | Bright, clean surface |

| Internal Purity | Trapped gases remain | Outgassing (Purifies metal) |

| Joining | Requires Flux (Messy) | Flux-free Brazing (Clean) |

When Good Enough Isn't Enough

You choose a vacuum furnace when the margin for error is zero.

If you are sintering parts for an aerospace engine, a microscopic oxide layer is a catastrophic failure mode. If you are brazing medical devices, you cannot have chemical flux residue.

This is where KINTEK steps in.

We understand that the vacuum furnace is the bridge between a raw material and a high-performance component. Whether you are dealing with the reactivity of titanium or the density requirements of powder metallurgy, the equipment must be as reliable as the physics it employs.

KINTEK provides the vessels for this precision. Our equipment is designed for labs that demand the absolute absence of contamination.

Are you ready to stop fighting the atmosphere?

High-purity processing requires more than just heat; it requires a partner who understands the delicate balance of pressure, temperature, and time.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

Related Articles

- The Symphony of Silence: Molybdenum and the Architecture of the Vacuum Hot Zone

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries