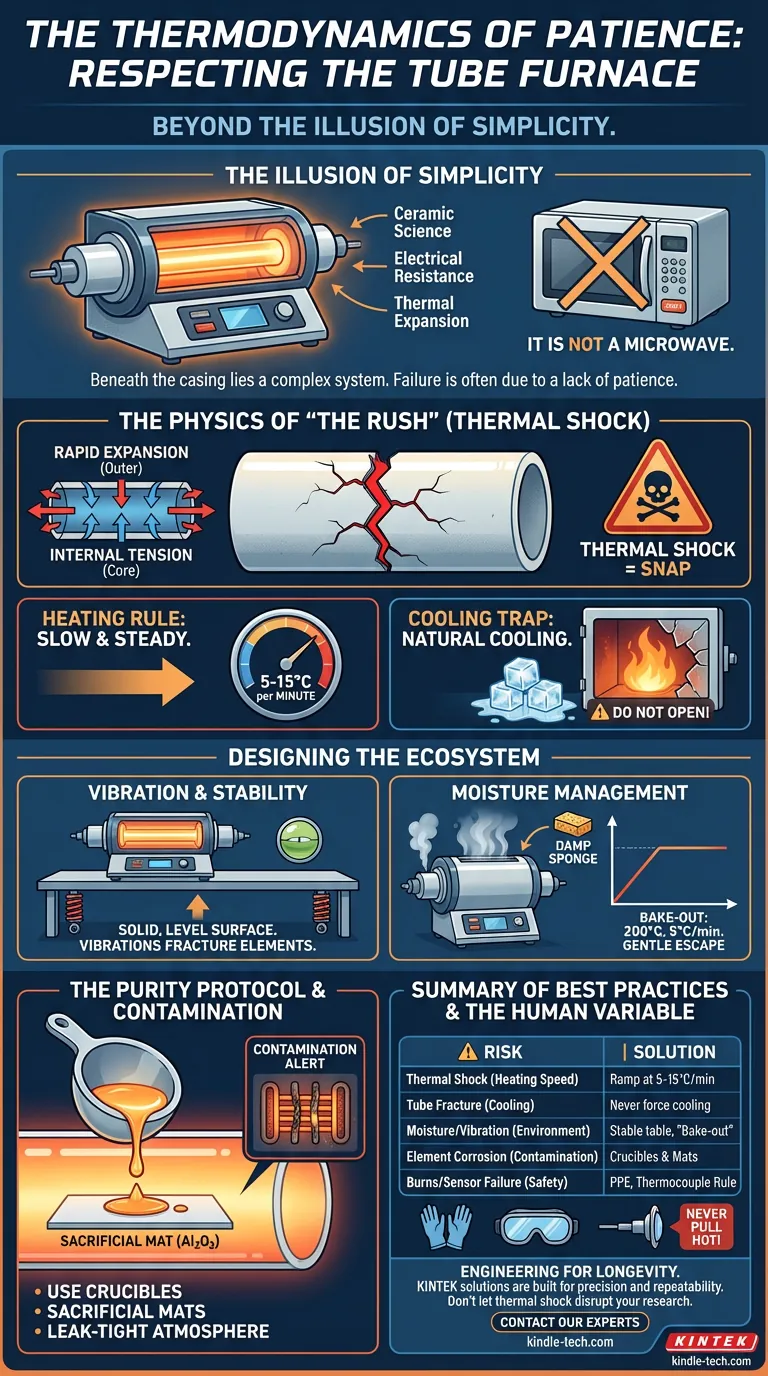

The Illusion of Simplicity

A tube furnace looks deceptively simple. It is a box that gets hot.

Because of this simplicity, it is often treated like a kitchen microwave. We punch in the numbers, hit start, and expect immediate results. We assume the machine is indifferent to how we treat it.

This is a dangerous fallacy.

Beneath the metal casing lies a complex relationship between ceramic science, electrical resistance, and thermal expansion. When a tube furnace fails—when a tube cracks or an element burns out—it is rarely a manufacturing defect.

It is almost always a failure of patience.

To operate a tube furnace successfully, you must stop thinking like a cook and start thinking like a materials engineer. You are managing stress.

The Physics of "The Rush"

The most common cause of furnace death is thermal shock.

Ceramics and heating elements (like silicon carbide) are brittle. They possess immense strength against heat but almost zero defense against rapid changes in that heat.

When you ramp up the temperature too quickly, the outer surface of the material expands faster than the core. This creates internal tension. Eventually, the tension exceeds the material's tensile strength.

Snap.

The Rule of Gradualism

If you want your equipment to last, you must embrace the slow game.

- Heating: Never rush the lower temperature range. Set a rate between 5-15°C per minute.

- Expansion: Allow the system to expand uniformly. A slow ramp allows the heat to soak through the material evenly.

The Cooling Trap

The most dangerous moment is often after the experiment is done. The operator is tired. They want to go home.

The temptation to crack the furnace door or remove insulation to "speed up" cooling is overwhelming.

Do not do it.

A rush of cool room-temperature air into a 1000°C chamber is a violent event. It is the thermal equivalent of hitting a glass window with a hammer. Let the furnace cool naturally according to its programmed cycle.

Designing the Ecosystem

In surgery, outcomes are determined not just by the surgeon's hand, but by the sterility of the room. The same applies here.

A furnace cannot function in chaos.

Vibration: The furnace must sit on a solid, level surface. Vibrations are subtle, but over months, they will fracture delicate heating elements.

Moisture: If a furnace has been sitting idle, it acts like a sponge. The insulation absorbs atmospheric water. If you heat a damp furnace to 1000°C instantly, that water turns to steam and expands explosively within the insulation walls.

Perform a "bake-out." Heat it slowly (5°C/min) to 200°C and hold it there. Let the moisture escape gently.

The Purity Protocol

High-temperature environments are unforgiving of contamination.

Matter behaves differently at extreme heat. Solids become liquids; liquids become gases.

If you inject liquids directly into a tube, or if a sample melts and spills, you have compromised the vessel. The contaminant reacts with the tube or the heating elements, degrading them permanently.

The Defense Strategy

- Crucibles: Always use high-purity alumina crucibles for materials that might melt.

- Sacrificial Mats: Place a layer of aluminum oxide powder or a ceramic mat beneath your sample. If a spill occurs, you sacrifice the mat, not the expensive tube.

- Atmosphere: If using inert gases, ensure the system is leak-tight. Oxygen leaking into a reducing atmosphere isn't just bad for the sample; it can destroy specific heating elements.

The Human Variable

Finally, we must address the operator.

We often forget that 500°C looks exactly like 20°C. There is no visual cue for "dangerously hot" until it is too late.

The Thermocouple Rule: Never pull a thermocouple out of a hot furnace. The shock of the temperature gradient will destroy the sensor instantly.

PPE as Habit: Wear heat-resistant gloves and safety glasses. Not because you expect an accident, but because the cost of being wrong is too high.

Summary of Best Practices

| Variable | The Risk | The Solution |

|---|---|---|

| Heating Speed | Thermal Shock | Ramp at 5-15°C/min. Patience is protection. |

| Cooling | Tube Fracture | Never force cooling. Keep the door closed. |

| Environment | Moisture/Vibration | Ensure a stable table. "Bake-out" idle furnaces. |

| Contamination | Element Corrosion | Use crucibles and sacrificial mats. |

| Safety | Burns/Sensor Failure | Use PPE. Never remove hot thermocouples. |

Engineering for Longevity

A tube furnace is an investment in precision. When you respect the physics of the machine, it rewards you with repeatability.

At KINTEK, we don't just supply equipment; we supply the expertise required to keep that equipment running for years. From high-purity consumables to robust furnace designs, our solutions are built for the rigorous demands of the modern laboratory.

Do not let thermal shock disrupt your research.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Why Your Furnace Components Keep Failing—And the Material Science Fix

- Installation of Tube Furnace Fitting Tee

- Entropy and the Alumina Tube: The Art of Precision Maintenance

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters