You’ve followed the heat treatment protocol to the letter. The component, a critical nickel-based alloy part, was machined perfectly. Yet, as you open the furnace, the pristine metallic sheen is gone, replaced by an inconsistent patchwork of brown, black, or gray. This isn't just a cosmetic issue; it's a red flag for compromised material properties, potential part failure, and costly rework. The question is, what went wrong?

The answer is rarely a single mistake. More often, it's a battle against an invisible enemy—a complex interplay of factors that turn your controlled process into an unpredictable outcome.

The Four Saboteurs of Heat Treatment

Discoloration is simply a chemical reaction. Elements on the alloy's surface (like chromium, nickel, and aluminum) react with microscopic contaminants in the furnace environment to form colored oxides and compounds. Understanding these contaminants is the first step to defeating them. This challenge isn't about one giant foe, but four distinct saboteurs that can infiltrate your process.

Saboteur #1: The Atmosphere

This is the most critical battlefield. The "vacuum" or "inert gas" in your furnace is never perfectly pure.

- Residual Oxygen: Even trace amounts cause damage. With oxygen levels above just 50 parts per million (ppm), chromium in the alloy will oxidize, forming a brown film (Cr₂O₃). If levels exceed 100 ppm, the nickel itself oxidizes, creating a tell-tale black surface (NiO).

- Moisture (H₂O): A tiny leak in a furnace seal or impure argon/nitrogen gas (with moisture >10 ppm) introduces water vapor. At high temperatures, this leads to "oxygen-hydrogen corrosion," creating oxides and, more dangerously, potentially releasing hydrogen that can penetrate the material and cause hydrogen embrittlement.

- Carbon & Sulfur Contamination: Volatile organic compounds from residual cutting fluids or oils in the furnace create a carbon-rich atmosphere. This can form a black or dark gray "carburized layer" on your part. Similarly, trace sulfur can react with nickel to form nickel sulfide (NiS), which not only causes a dark brown surface but also leads to "hot brittleness"—a catastrophic loss of strength at high temperatures.

Saboteur #2: The Process Parameters

How you heat and cool is as important as the atmosphere itself.

- Heating/Cooling Rate: A rapid heating rate (>20℃/min) can cause the part's surface to oxidize before the core reaches temperature, creating uneven, localized discoloration. Conversely, slow cooling prolongs the time the part spends at high temperatures, allowing oxide layers to thicken and darken.

- Temperature and Time: The higher the temperature and the longer the holding time, the more intense the reactions. Even in a low-oxygen environment, excessive time at temperature (e.g., >4 hours) allows for cumulative oxidation, leading to a darker finish.

Saboteur #3: Surface Preparation

The battle begins before the part even enters the furnace.

- Residual Impurities: Incomplete pre-cleaning leaves a minefield of contaminants. Fingerprints contain salts and grease. Cutting fluids leave behind oils. At high temperatures, these residues carbonize or react with the alloy, creating black films and localized corrosion spots.

Saboteur #4: The Equipment Itself

Your furnace can become an unwilling accomplice.

- Furnace Leaks: Aging seals or improperly closed doors are open invitations for air to seep into the furnace chamber, constantly feeding oxygen to your process and undermining any atmospheric control.

- Internal Contamination: Over time, furnace components like heating elements can degrade. An oxidizing molybdenum foil heating element, for example, can volatilize and deposit gray MoO₃ onto your part's surface, causing contamination.

From Reactive Fixes to Proactive Control

The breakthrough against discoloration isn't a magical new alloy; it's a systematic victory over these four saboteurs. Engineers who achieve consistent, flawless results don't just hope for the best. They wage a deliberate campaign of control, ensuring that every variable is managed with precision.

They achieve this by moving from a reactive mindset ("What caused this discoloration?") to a proactive one ("How do we build a process where discoloration is impossible?"). This requires eliminating uncertainty at every stage—from part cleaning to atmospheric purity to thermal profiling. But this level of control is impossible without the right tools.

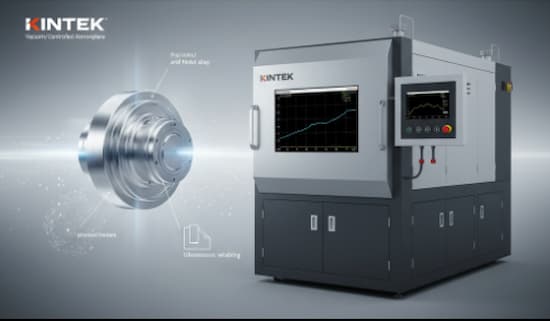

The Equipment That Makes Predictable Outcomes Possible

Achieving this level of process integrity isn't about guesswork; it's about deploying laboratory equipment designed for precision and reliability. This is where the theory of heat treatment meets the reality of execution.

-

To defeat atmospheric saboteurs: You need more than just a box that gets hot. A high-integrity vacuum or controlled-atmosphere furnace is essential. The key is verifiable low leak rates to starve the oxidation reaction of oxygen and moisture. This is complemented by high-purity gas delivery systems and purifiers that ensure the inert gas you introduce isn't a source of contamination itself.

-

To master process parameters: Repeatability is paramount. Modern furnaces with programmable, high-precision temperature controllers allow you to execute exact heating, soaking, and cooling profiles every single time, eliminating the variability that leads to inconsistent oxide layers.

-

To guarantee surface cleanliness: The foundation of a good result is a perfectly clean surface. Professional-grade ultrasonic cleaners, paired with appropriate laboratory-grade cleaning consumables, are the only way to reliably remove the microscopic oils and salts that manual cleaning can miss.

By investing in equipment that provides this fundamental level of control, you are not just buying a furnace or a cleaner. You are acquiring the capability to eliminate the root causes of discoloration and failure.

From Consistent Parts to a Competitive Edge

Eliminating discoloration is more than just an aesthetic victory. It's a direct indicator of a well-controlled process, which translates into tangible business value. A process that consistently prevents discoloration also prevents the underlying issues of intergranular corrosion and hydrogen embrittlement. This means higher component reliability, dramatically reduced scrap and rework rates, and faster delivery of critical parts for industries like aerospace, medical, and energy. Ultimately, mastering the heat treatment process isn't just about technical excellence—it's about building a reputation for uncompromising quality and creating a durable competitive advantage.

Every failed part tells a story about a process that has fallen short. If you're tired of unpredictable outcomes and want to transform your heat treatment process from a source of problems into a pillar of reliability, it's time to look at the tools you're using. Whether you're struggling with discoloration, aiming for specific mechanical properties, or scaling your production, the root cause of success or failure often lies in the precision of your process control. Our specialists can help you diagnose the unique challenges in your workflow and identify the right equipment to overcome them. To build a more predictable and profitable heat treatment process.

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

Related Articles

- The Architecture of Nothingness: Anatomy of a Vacuum Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?