It’s a scenario that plays out in labs everywhere. You have a critical project, a new aluminum alloy to develop, or a quality control test to run. You load the aluminum charge into your induction furnace—a powerful tool that handles other metals with ease. But this time, it’s different.

The melting process is painfully slow. The temperature struggles to climb, and when it does, it’s unstable. You end up wasting hours, wrestling with the equipment, only to get an inconsistent melt or, worse, a failed run. You start to question everything: Is the crucible contaminated? Is this a bad batch of aluminum? Is the furnace malfunctioning?

This isn't just a minor inconvenience; it's a significant bottleneck.

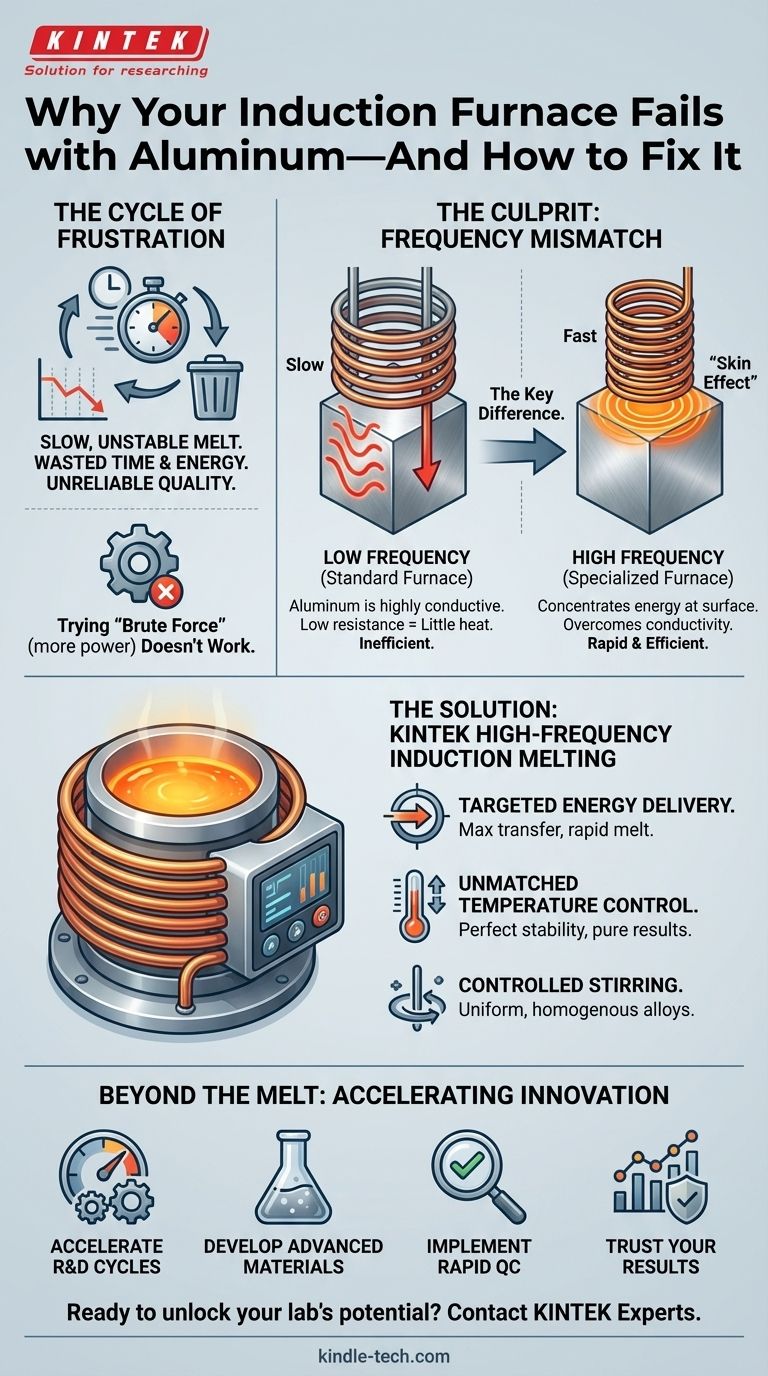

The Cycle of Frustration: Why 'Trying Harder' Doesn't Work

When faced with this problem, the typical response is to apply brute force. You might crank up the power, run the cycle for longer, or try to melt smaller, more manageable quantities. But the results are rarely better. You're simply burning more energy and time, with the same frustrating outcome.

These struggles have real business consequences:

- Project Delays: R&D timelines get pushed back as teams spend days on what should be a simple melting task.

- Increased Costs: Wasted electricity and man-hours drive up operational expenses for every failed or inefficient run.

- Unreliable Quality: Inconsistent melting leads to inconsistent alloy composition, making it impossible to produce materials that meet tight specifications. Your results become non-repeatable.

Many labs conclude that induction melting is simply not a good fit for aluminum. But that conclusion, while understandable, is incorrect. They are missing a critical piece of the puzzle.

The Real Culprit: A Mismatch of Frequency and Physics

The problem isn’t your process or your furnace’s power. It's a fundamental mismatch between the physics of aluminum and the operating frequency of a standard induction furnace.

Here’s the simple explanation:

Induction furnaces work by generating a strong, alternating magnetic field. This field creates electrical currents—called "eddy currents"—inside the metal itself. The metal's natural resistance to these currents generates intense heat, melting it from the inside out.

However, aluminum is an excellent electrical conductor. It’s like a frictionless highway for electricity. This high conductivity means it puts up very little resistance to the eddy currents generated by a low-frequency magnetic field (the kind used in standard iron-melting furnaces). With little resistance, very little heat is generated.

To heat aluminum efficiently, you need to concentrate the energy. This is achieved by using a furnace that operates at a medium to high frequency.

Think of it like pushing a child on a swing. If you push at a slow, random rhythm (low frequency), you'll barely get the swing moving. But if you time your pushes to match the swing's natural arc (high frequency), you transfer energy efficiently and send it soaring.

A high-frequency field creates a phenomenon known as the "skin effect," which concentrates the heating currents in a thin outer layer of the aluminum. This overcomes the metal's high conductivity, allowing for incredibly fast and efficient energy transfer.

This is why your attempts to simply "add more power" failed. You weren't speaking the right physical language. A low-frequency furnace, no matter how powerful, is simply the wrong tool for the job.

The Right Tool for the Right Physics: High-Frequency Induction Melting

To solve this problem permanently, you don’t need a workaround. You need a tool that is engineered from the ground up with the physics of aluminum in mind. You need a furnace that can deliver the precise, high-frequency energy required for a rapid, controlled, and repeatable melt.

This is the exact principle behind KINTEK's specialized laboratory induction furnaces. They aren't just generic heaters; they are precision instruments designed to address these specific metallurgical challenges.

Our high-frequency induction furnaces directly solve the root cause of the problem:

- Targeted Energy Delivery: By operating at the optimal medium-to-high frequency, our systems ensure maximum energy is transferred directly into your aluminum charge, guaranteeing rapid melt times and exceptional energy efficiency.

- Unmatched Temperature Control: The clean, contained nature of induction heating, combined with our precise digital controls, allows you to maintain a perfectly stable temperature. This is critical for creating homogenous alloys and managing the formation of aluminum oxide (dross).

- Controlled Stirring for Homogeneity: The magnetic field naturally stirs the molten metal, ensuring all alloying elements are perfectly mixed for uniform, high-purity results, every single time.

Our furnaces are not a happy accident; they are the direct result of understanding the science and engineering a solution that works with the properties of the material, not against them.

Beyond the Melt: Accelerating Innovation When Your Process Just Works

When you eliminate the fundamental bottleneck of melting, you unlock new potential for your entire lab. The conversation shifts from "How can we get this to melt?" to "What can we create next?"

With a reliable and repeatable melting process, you can now:

- Accelerate R&D Cycles: Run multiple alloy experiments in a single day, instead of spending a week on one problematic batch.

- Develop Advanced Materials: Confidently create high-purity, specification-critical aluminum alloys for demanding applications in aerospace, automotive, or medical fields.

- Implement Rapid QC: Quickly and accurately test incoming materials or production samples, ensuring quality and preventing downstream issues.

- Trust Your Results: Generate consistent, repeatable data that gives you full confidence in your research and development outcomes.

Melting aluminum transforms from a source of frustration into a predictable, reliable, and enabling step in your workflow.

Solving a persistent technical challenge is about more than just getting a single task done; it's about removing a barrier to innovation. If your lab is ready to move past the limitations of your current equipment and accelerate your materials science projects, our team of specialists is here to help. We can work with you to understand your unique challenges and configure a system that delivers the performance and reliability you need. Contact Our Experts.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Induction Melting Spinning System Arc Melting Furnace

Related Articles

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries