You’ve done everything by the book. You invested in a modern, efficient induction furnace, expecting to produce clean, high-quality metal. You meticulously set the temperature, run the cycle, and pour the melt. But when the results come back from quality control, your heart sinks. The metal is brittle, the composition is off, and it’s riddled with impurities. It's another failed batch, and you’re back to square one, wondering what you did wrong.

If this scenario feels painfully familiar, you are not alone.

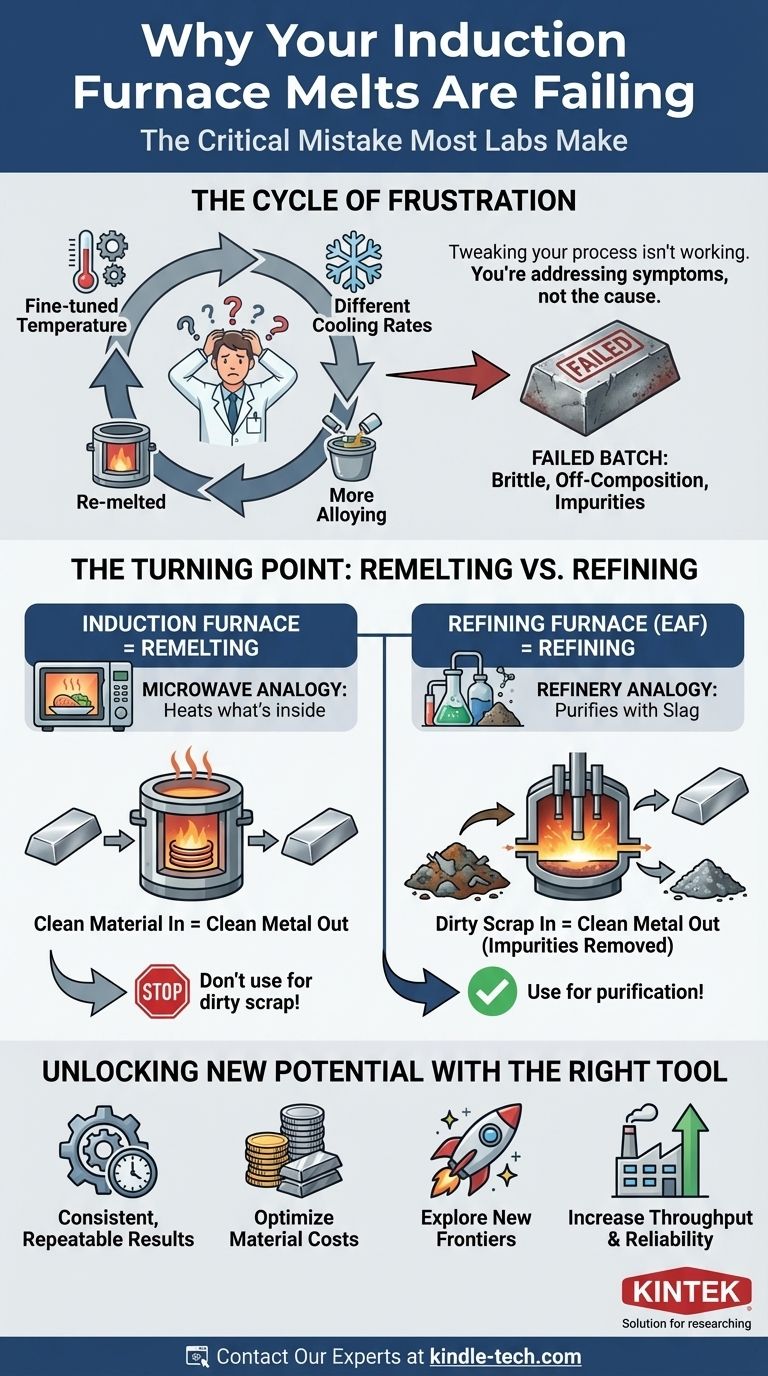

The Cycle of Frustration: Why Tweaking Your Process Isn't Working

This is a story we hear frequently from labs and foundries. A team invests in induction technology for its renowned speed, precision, and energy efficiency, only to get locked in a frustrating cycle of trial and error.

In an attempt to fix the problem, you might have:

- Obsessively fine-tuned the temperature controls, hoping a few degrees here or there would solve it.

- Tried different cooling rates, suspecting the issue was in the solidification process.

- Added more expensive alloying elements to compensate for what you assume was lost in the melt.

- Simply re-melted the batch, hoping it was a one-time fluke.

None of it works consistently. The commercial consequences are severe: project deadlines are missed, R&D timelines are extended, and you’re forced to either discard expensive materials or purchase ultra-pure, high-cost raw materials, negating any cost savings you hoped to achieve. You start to lose confidence in your equipment and your process.

But the problem isn't your process. It's a fundamental misunderstanding of what your furnace is actually designed to do.

The Turning Point: Are You Remelting or Refining?

The breakthrough comes when you stop asking, "How can I fix my induction melting process?" and start asking, "What is the real job of an induction furnace?"

The single greatest source of confusion is the difference between remelting and refining.

An induction furnace is a world-class remelting device. It is not a refining tool.

The Microwave vs. The Refinery: A Simple Analogy

Think of your induction furnace like a powerful, precise microwave oven. If you put a perfectly prepared, high-quality meal into a microwave, you get a perfectly heated, high-quality meal out. But if you put in raw, unseasoned, or spoiled ingredients, the microwave will just give you hot, raw, unseasoned, or spoiled ingredients. It heats what's inside; it doesn't transform its fundamental quality.

This is exactly how an induction furnace works. It takes clean, known-composition metal and melts it with unparalleled efficiency. If you put clean material in, you get clean metal out.

A refining furnace, like an Electric Arc Furnace (EAF), is more like a chemical refinery. It doesn't just melt; it purifies. These furnaces use a layer of special materials called slag, which acts like a chemical sponge, actively pulling impurities like phosphorus and sulfur out of the molten metal. They are designed to take dirty, oxidized, or unknown scrap and transform it into a cleaner, specified product.

The "common solutions" you tried earlier were failing because they were like trying to purify dirty water by boiling it harder. You aren't addressing the source of the problem: the initial impurities in your charge material, which your furnace has no capacity to remove.

Choosing the Right Tool for the Job, Not Just the Trendiest One

To get predictable, high-quality results, you don't need a more complicated process. You need to match your tool to your raw material. The solution is to step back and assess your goal:

- If you are melting high-purity, pre-cleaned scrap or certified alloys to create a precise final product, an induction furnace is the most efficient, clean, and cost-effective tool you can choose.

- If you need to process low-cost, oxidized, or compositionally unknown scrap, you require a furnace with active refining capabilities.

This is where a true equipment partner adds value. At KINTEK, we don't just sell lab equipment; we help you solve problems. Our approach is built on a deep understanding of these core metallurgical principles. We don't start by recommending a product. We start by asking about your raw materials, your final product specifications, and your operational goals.

Our range of lab-scale furnaces is not a one-size-fits-all offering. It's a curated portfolio designed to provide the right tool for the right job. Whether you need the surgical precision of an induction furnace for high-purity work or the robust refining power for more variable materials, our expertise ensures you get the equipment that actually solves your problem.

Beyond Fixing Problems: Unlocking New Potential in Your Lab

When you stop fighting your equipment and start using the right tool, everything changes. The unpredictability vanishes. Your lab is no longer a source of frustration, but a hub of innovation.

With the correct furnace technology in place, you can:

- Achieve Consistent, Repeatable Results: Dramatically accelerate your R&D and quality control, knowing your equipment is a stable variable.

- Optimize Your Material Costs: Confidently use the most cost-effective raw materials for your specific process, whether that means leveraging low-cost scrap with a refining furnace or maximizing the efficiency of an induction furnace with pure alloys.

- Explore New Frontiers: Undertake more ambitious projects to develop novel alloys, knowing that your results are a true reflection of your science, not a limitation of your tools.

- Increase Throughput and Reliability: Eliminate wasted batches, reduce energy consumption, and deliver reliable results on time, every time.

Solving this melting problem is about more than just getting a clean cast. It's about building a more efficient, predictable, and innovative operation. If you're ready to move past the frustration and find a lasting solution tailored to your specific projects, our team is here to help you navigate the choice. Let's discuss your unique challenges and find the right equipment to unlock your lab's full potential. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

Related Articles

- Beyond Heat: The Tube Furnace as a Controlled Micro-Environment

- Your Tube Furnace Is Not the Problem—Your Choice of It Is

- The Glass Ceiling: Navigating the True Thermal Limits of Quartz Tube Furnaces

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again