You’ve followed every step. The crucible is new, the power is on, and the electric furnace is humming, glowing a fierce orange. But inside, the steel billet just sits there, stubbornly solid. It might glow cherry-red, but it refuses to liquefy. Hours pass. Energy bills climb. Your project, which depends on this single step, is now at a standstill.

If this scene feels painfully familiar, you are not alone. It’s one of the most common and frustrating roadblocks in small-scale metallurgy and materials science.

The Vicious Cycle: Why 'More Power' Isn't the Answer

Faced with a failed melt, many intelligent people start a predictable—and often expensive—process of elimination. "Maybe the furnace isn't powerful enough," they think, leading them to purchase a larger, more power-hungry model, only to face the same result. Others blame the crucible, the ambient temperature, or even the specific steel alloy.

These efforts, while logical, are almost always dead ends. They are attempts to treat the symptoms of a problem that is far more fundamental.

The business consequences of this misunderstanding are significant.

- Project Delays: Research and development timelines are shattered, delaying new product innovations or critical material tests.

- Wasted Capital: Money is spent on equipment that is fundamentally wrong for the task. The cost isn't just the furnace itself, but the immense amount of wasted electricity.

- Limited Capabilities: Labs and workshops remain stuck working with low-melting-point metals like aluminum or brass, unable to innovate with high-strength steel and iron alloys.

The core of the issue isn't about how much heat you're generating, but how you're generating it.

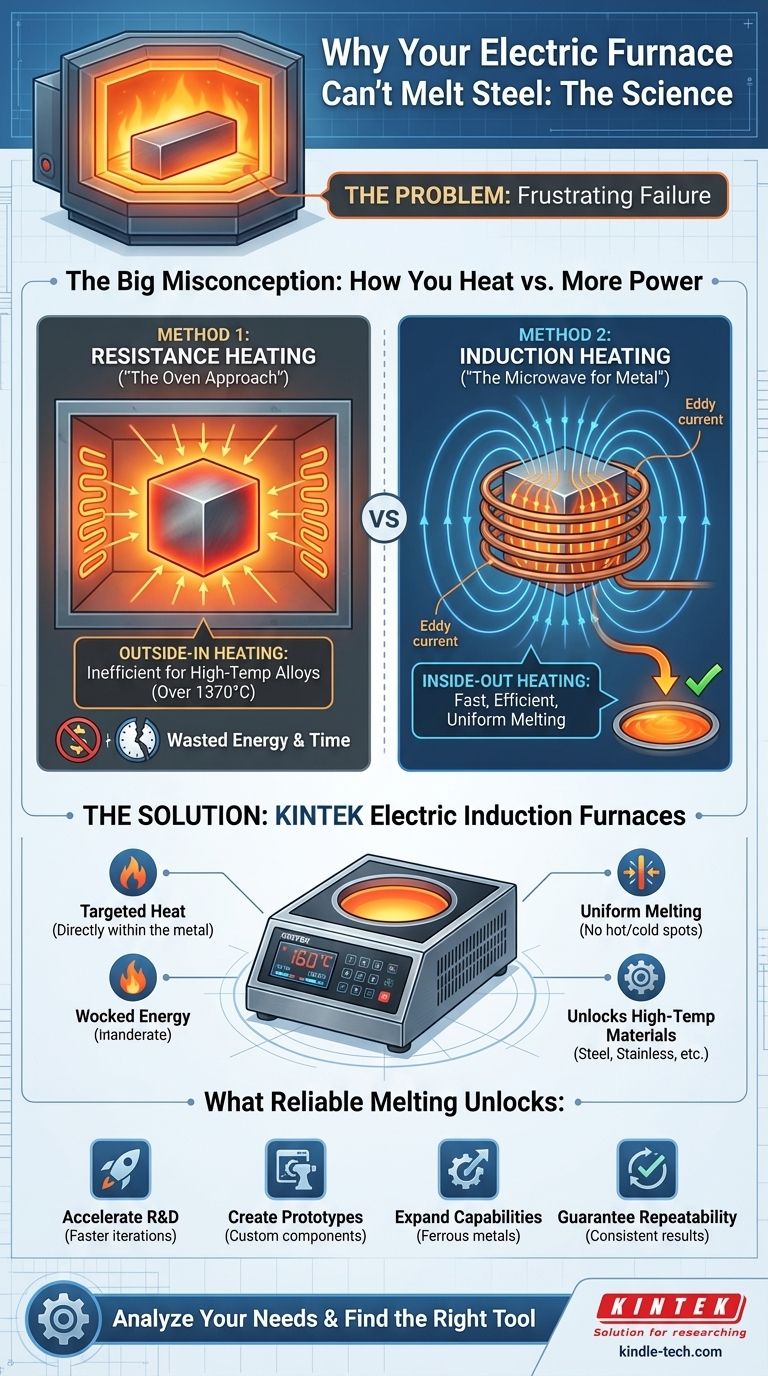

The Big Misconception: Two Worlds of Electric Heating

The term "electric furnace" is misleadingly broad. It describes two fundamentally different technologies that operate on entirely separate physical principles. Choosing the wrong one for steel isn't a matter of preference; it's a matter of physics.

Method 1: The 'Oven' Approach (Resistance Heating)

Most common, lower-cost electric furnaces use resistance heating. They work just like a kitchen oven or a toaster. Electricity flows through heating elements, which get extremely hot and radiate that heat towards the object inside the furnace.

This is an "outside-in" heating method. For steel, which has a melting point over 1370°C (2500°F), this is incredibly inefficient. You are trying to "bake" a dense piece of metal until its core reaches a scorching temperature. By the time the core is even close to melting, you've wasted enormous amounts of energy and time simply heating the air and the outer layers of the metal. It’s like trying to cook a frozen turkey in 10 minutes by setting the oven to its highest temperature—you’ll just burn the outside while the inside remains solid.

This is why your resistance furnace fails. It was never designed for this job.

Method 2: The 'Microwave' for Metal (Induction Heating)

An electric induction furnace works on a completely different principle. Instead of external heating elements, it uses a copper coil to generate a powerful, high-frequency magnetic field. When a conductive material like steel is placed inside this field, the field creates massive electrical currents within the steel itself.

These currents, called eddy currents, generate intense heat due to the metal's own electrical resistance. The steel is heated uniformly from the "inside-out."

It's not just warming the metal; it's agitating the very molecules of the steel until they generate their own heat. This is why induction is so fast, efficient, and capable of easily exceeding the high melting point of steel.

The Right Tool: A Solution Engineered from First Principles

To reliably melt steel, you don't need a hotter oven; you need a tool designed specifically for inside-out heating.

This is the foundational principle behind KINTEK's Electric Induction Furnaces. They are not simply "hot boxes." They are precision instruments engineered to leverage the physics of induction for maximum efficiency and control. Our furnaces directly address the root cause of failure that plagues so many labs:

- Targeted Heat: By inducing heat directly within the steel, our furnaces bypass the slow, inefficient process of radiative heating. This means faster melt times, less wasted energy, and predictable results.

- Uniform Melting: The inside-out heating ensures the entire sample reaches its melting point uniformly, producing a higher-quality, homogenous melt without hot or cold spots.

- Unlocking High-Temp Materials: Our induction systems are built to consistently and safely reach the extreme temperatures required for steel, stainless steel, and other high-performance alloys, opening the door to more advanced projects.

Our equipment is the embodiment of the solution—a tool born from a deep understanding of the problem.

Beyond a Simple Melt: What Reliable Steel Melting Unlocks

When you finally solve the recurring problem of melting steel, it’s about more than just one successful experiment. It’s about unlocking a new level of capability for your entire operation.

With a reliable and efficient induction furnace, you can now:

- Accelerate R&D: Instead of one failed melt taking a full day, you can perform multiple successful melts, dramatically increasing your iteration speed for developing new alloys.

- Create High-Value Prototypes: Quickly and easily produce custom steel components for functional testing, moving your projects from concept to reality faster than ever.

- Expand Your Lab's Scope: Confidently take on projects involving ferrous metals and other high-temperature alloys, expanding your service offerings and research potential.

- Guarantee Repeatability: Eliminate the guesswork and achieve consistent, high-quality results for every single melt, ensuring the integrity of your research and products.

Solving this fundamental challenge moves your work from a state of frustration and uncertainty to one of speed, precision, and innovation. If your projects have been limited by the capabilities of your current equipment, it's time to address the root cause of the problem.

Let our team of specialists help you move past frustrating failures and unlock the full potential of your lab. We can help you analyze your specific material and throughput needs to ensure you have the right tool for the job, once and for all. Let's discuss your project. Contact Our Experts

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

Related Articles

- Why Your Furnace Components Keep Failing—And the Material Science Fix

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Your Tube Furnace Is Not the Problem—Your Choice of It Is

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

- From Crack to Complete: A Scientist's Guide to Eliminating Catastrophic Tube Furnace Failures