In almost all cases, no, heat press attachments are not interchangeable between different brands. While it seems like a simple component, an attachment is part of a proprietary electrical system. Manufacturers use unique connectors, wiring configurations, and temperature sensors, meaning an attachment from one brand is highly unlikely to work with the control box of another.

The core issue isn't the physical shape of the attachment, but its electrical DNA. Each brand designs its control box and attachments to be a closed ecosystem, and attempting to mix them risks equipment damage, inaccurate results, and voided warranties.

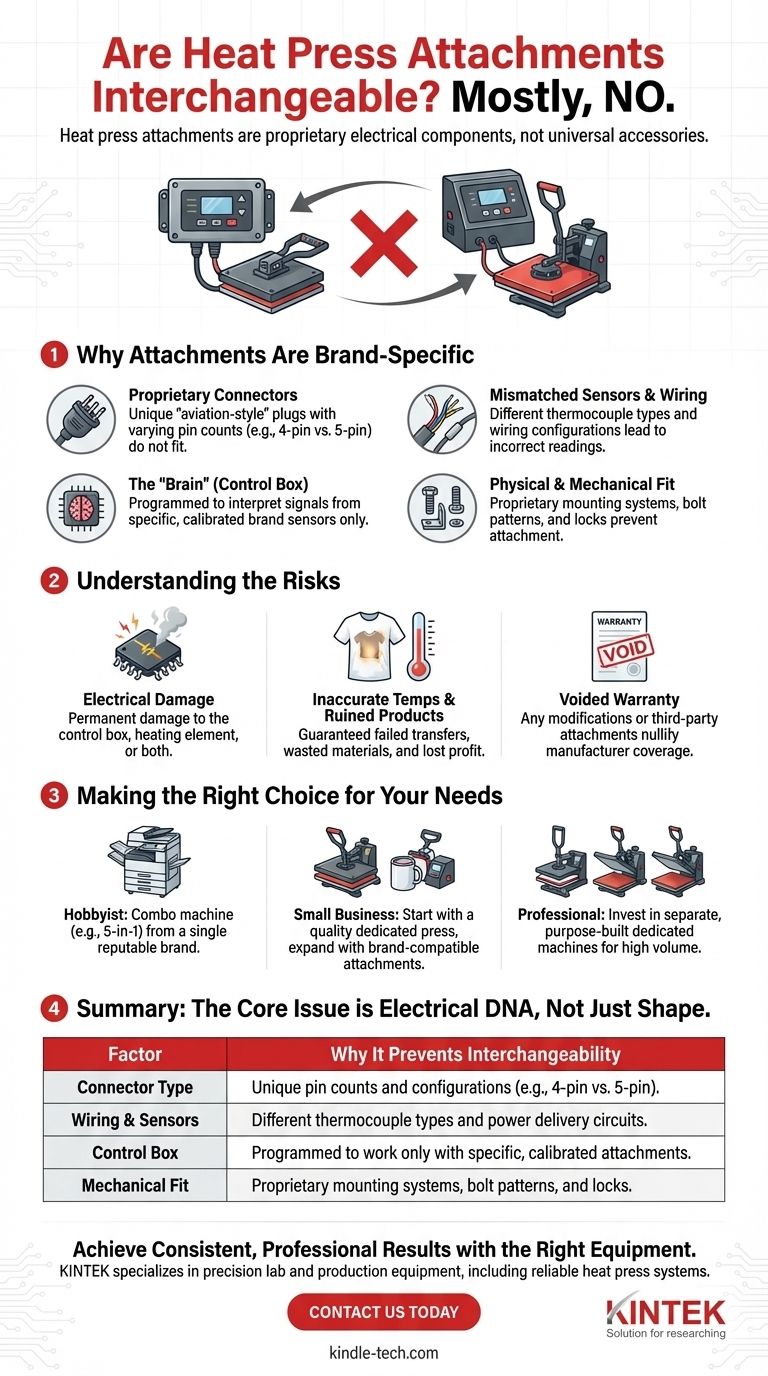

Why Attachments Are Brand-Specific

To understand the lack of universal compatibility, you need to look past the metal and see the electronics. The attachment and the control box are two halves of a single, calibrated system.

The Critical Role of the Connector

The most immediate barrier is the physical plug that connects the attachment to the control unit. These are not standardized like a USB or wall outlet.

Manufacturers use different "aviation-style" connectors with varying pin counts (e.g., 4-pin, 5-pin, 6-pin). A 4-pin plug from Brand A simply will not fit into a 5-pin socket from Brand B.

Mismatched Power and Temperature Sensors

Even if a connector happens to fit, the internal wiring is almost certainly different. The pins in the connector have specific jobs: two might deliver power to the heating element, while others connect to the temperature sensor.

Brands use different types of sensors (thermocouples) and wire them to different pins. Plugging in an incompatible attachment can send the temperature reading to the wrong circuit or send power where it doesn't belong.

The "Brain" of the Operation: The Control Box

Think of the control box as the brain. It's programmed to interpret signals from a very specific type of temperature sensor and to send a precise amount of power to a specific heating element.

Connecting a foreign attachment is like giving the brain signals in a language it doesn't understand. This leads to dangerously incorrect temperature regulation.

Physical and Mechanical Fit

Beyond the electronics, the mechanical system for how an attachment mounts to the main press frame is also proprietary. The bolt patterns, locking mechanisms, and support structures are unique to each manufacturer's design.

Understanding the Trade-offs and Risks

Attempting to force compatibility by splicing wires or using adapters is a risky approach that often creates more problems than it solves.

The Danger of Electrical Mismatch

The most severe risk is permanent electrical damage. Sending power down the wrong wire can instantly short out the circuitry in your control box, the heating element in the attachment, or both. This often results in a completely dead unit.

Inaccurate Temperatures and Ruined Products

If the system powers on but uses an incompatible sensor, the control box will display an incorrect temperature. It might read 350°F while the heating element is actually at 250°F or 450°F.

This guarantees failed transfers. You will either under-cure your items, causing the design to wash out, or scorch them, ruining your blank products and wasting materials.

Voiding Your Warranty

Using third-party attachments, especially if they require modification, will immediately void your manufacturer's warranty. If the control box fails for any reason, you will be left with the full cost of replacement.

Making the Right Choice for Your Production Needs

Your equipment strategy should align directly with your business or hobby goals. Choosing the right path from the start prevents costly compatibility headaches later.

- If your primary focus is exploring different products as a hobbyist: A multifunction "combo" machine (like a 5-in-1 or 8-in-1) from a single reputable brand is the most economical way to begin.

- If your primary focus is building a small business: Start with a high-quality dedicated flat press and expand by buying compatible attachments or separate dedicated presses from that same brand ecosystem.

- If your primary focus is high-volume, professional production: Investing in separate, purpose-built dedicated machines for each function (e.g., flat press, mug press, hat press) offers the best performance, durability, and efficiency.

Ultimately, committing to a single, reliable brand ecosystem is the surest path to consistent results and equipment longevity.

Summary Table:

| Factor | Why It Prevents Interchangeability |

|---|---|

| Connector Type | Unique pin counts and configurations (e.g., 4-pin vs. 5-pin). |

| Wiring & Sensors | Different thermocouple types and power delivery circuits. |

| Control Box | Programmed to work only with specific, calibrated attachments. |

| Mechanical Fit | Proprietary mounting systems, bolt patterns, and locks. |

Achieve Consistent, Professional Results with the Right Equipment

Don't risk damaging your equipment or ruining products with incompatible attachments. KINTEK specializes in precision lab and production equipment, including heat press systems designed for reliability and performance. Our experts can help you select the right press and compatible attachments for your specific needs—whether you're a hobbyist exploring new products or a professional running a high-volume operation.

Contact us today to discuss your production goals and find the perfect heat press solution from a trusted brand ecosystem!

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the primary function of a hydraulic press in SiC/Al-Zn-Mg-Cu extrusion? Mastering Material Deformation

- What is the function of axial pressure in hot pressing Al-4Cu alloys? Achieve Peak Densification and Strength

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is a hydraulic hot press? Unlock the Power of Heat and Pressure for Advanced Materials

- What is hot forging and when should it be used? Maximize Strength for Critical Components