Yes, gold can be induction heated. In fact, modern induction furnaces are a preferred method for melting gold in professional settings. The process works by using a powerful, high-frequency magnetic field to generate heat directly within the gold, leading to a fast, clean, and highly controlled melt.

Induction is not only a viable method for heating gold, but it is often the superior choice for achieving high-purity results. It overcomes gold's unique properties by using high-frequency magnetic fields to ensure rapid, contained, and contamination-free melting.

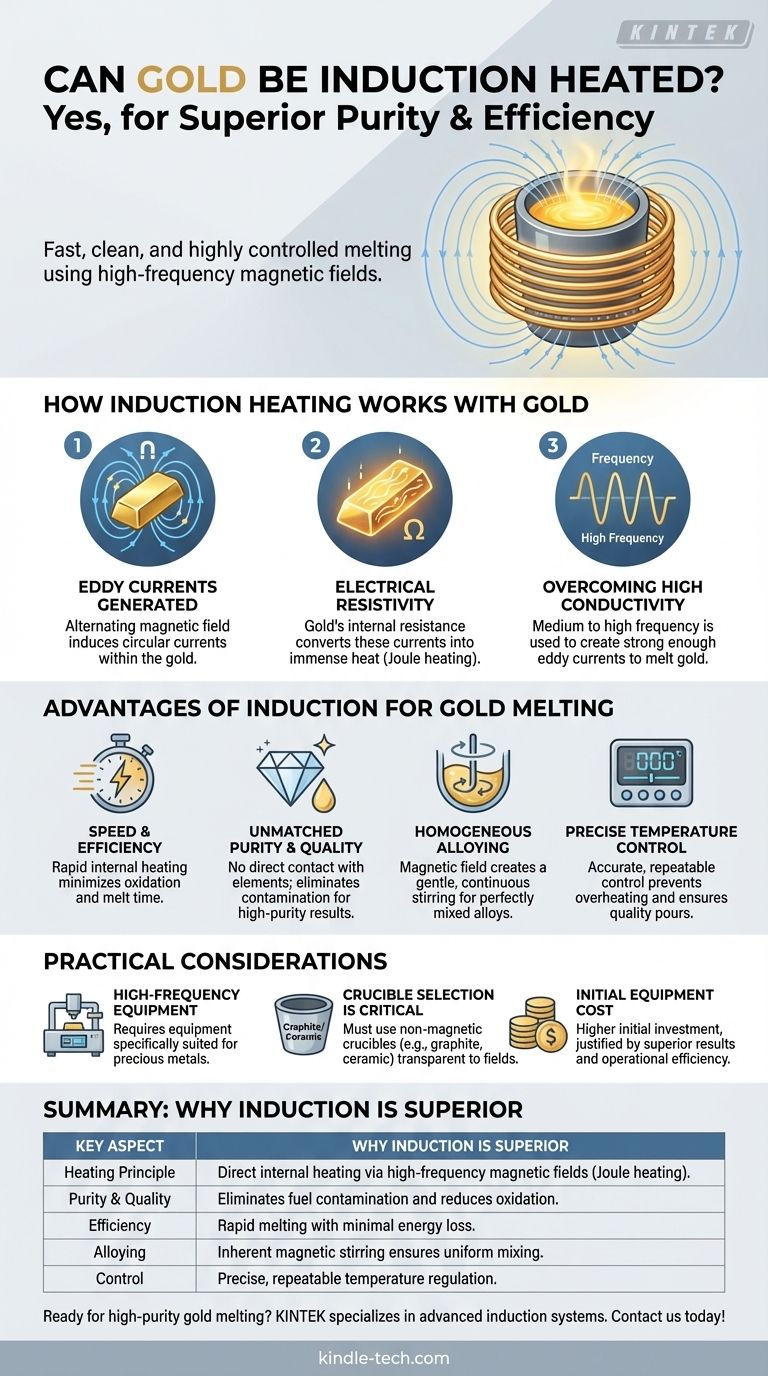

How Induction Heating Works with Gold

While induction is famously used for magnetic materials like iron and steel, the physics behind heating a non-magnetic metal like gold is slightly different but equally effective.

The Principle of Eddy Currents

An induction heater generates a powerful, rapidly alternating magnetic field. When conductive material like gold is placed within this field, the field induces small, circular electrical currents inside the metal. These are called eddy currents.

The Role of Electrical Resistivity

All materials have some resistance to the flow of electricity. As these induced eddy currents flow through the gold, they encounter this electrical resistivity. This friction generates immense heat, a principle known as Joule heating (or I²R loss), causing the gold to melt from the inside out.

Overcoming High Conductivity

Gold is an excellent electrical conductor, meaning it has very low resistivity. This makes it inherently more difficult to heat with eddy currents than less conductive metals.

The solution is to use an induction system that operates at a medium to high frequency. Increasing the frequency of the magnetic field change induces stronger eddy currents, generating enough power to overcome gold's low resistance and melt it efficiently.

The Advantages of Induction for Gold Melting

Using induction is not just possible; it offers significant advantages over traditional torch or resistance furnace methods, especially for achieving high quality.

Speed and Efficiency

Because heat is generated directly within the gold itself, the melting process is exceptionally fast. This minimizes the time the molten gold is exposed to the atmosphere, which is a critical factor for maintaining purity.

Unmatched Purity and Quality

The rapid heating cycle drastically reduces oxidation. Furthermore, since no part of the heating equipment directly touches the gold, it eliminates contamination from fuel or heating elements. This results in a cleaner, higher-quality melt.

Homogeneous Alloying

The magnetic field that creates the eddy currents also produces a gentle, continuous stirring effect in the molten metal. This is extremely beneficial when creating gold alloys, as it ensures all metals are mixed thoroughly and uniformly.

Precise Temperature Control

Modern induction systems offer precise, repeatable control over power output and temperature. This is crucial for avoiding overheating and ensuring the correct pouring temperature for casting, which directly impacts the quality of the final product.

Understanding the Practical Considerations

While powerful, the induction process for gold has specific requirements and trade-offs to consider.

The Need for High-Frequency Equipment

As mentioned, gold's high conductivity demands a higher frequency. This means you cannot use a low-frequency induction heater designed for steel to melt gold effectively. The equipment must be specifically suited for precious metals.

Crucible Selection is Critical

The gold is held within a crucible, which is placed inside the induction coil. This crucible must be made of a material that is transparent to magnetic fields, such as graphite or a specialized ceramic. This ensures the magnetic field passes through the crucible and heats the gold directly, not the container.

Initial Equipment Cost

The primary trade-off is cost. Professional induction melting systems represent a significant capital investment compared to simpler methods like a gas-fired furnace or a torch. However, for applications requiring high purity, speed, and repeatability, the investment is often justified by the superior results and operational efficiency.

Making the Right Choice for Your Goal

Deciding on a heating method depends entirely on your specific requirements for quality, volume, and cost.

- If your primary focus is high-volume, high-purity melting: Induction heating is the superior professional choice for its speed, precise control, and ability to minimize contamination.

- If your primary focus is small-scale artisan work or repairs: A traditional gas torch offers unmatched portability and a much lower initial cost, making it more practical for individual pieces.

- If your primary focus is creating consistent, high-quality alloys: The inherent magnetic stirring effect of induction provides a significant advantage for creating perfectly homogeneous gold alloys that other methods cannot easily replicate.

Ultimately, understanding the principles of induction heating empowers you to select the right tool for achieving your desired outcome with gold.

Summary Table:

| Key Aspect | Why Induction is Superior for Gold |

|---|---|

| Heating Principle | Uses high-frequency magnetic fields to generate eddy currents and internal heat (Joule heating). |

| Purity & Quality | Eliminates contamination from fuel/elements and reduces oxidation for high-purity results. |

| Efficiency | Rapid, direct internal heating minimizes melt time and energy loss. |

| Alloying | Magnetic stirring ensures homogeneous mixing of gold alloys. |

| Control | Precise temperature regulation prevents overheating and ensures consistent pours. |

Ready to achieve high-purity gold melting with precision and efficiency?

KINTEK specializes in advanced lab equipment and consumables, including induction melting systems tailored for precious metals like gold. Our solutions deliver the speed, purity, and control that professionals demand.

Contact us today to find the perfect induction heating system for your laboratory's needs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting