In essence, a vacuum induction melting (VIM) furnace is designed for processing high-purity and reactive metals. It is primarily used for materials where exposure to air during melting would be catastrophic to their final properties, including superalloys, specialty steels, reactive metals like titanium, and precious metals. While it can melt common ferrous and non-ferrous metals, its main purpose is to achieve a level of purity and chemical control that standard furnaces cannot.

The critical takeaway is that a VIM furnace isn't just for melting; it's a highly controlled refining tool. The vacuum environment serves two key purposes: it prevents contamination from atmospheric gases and actively purifies the metal by removing dissolved gases and volatile impurities.

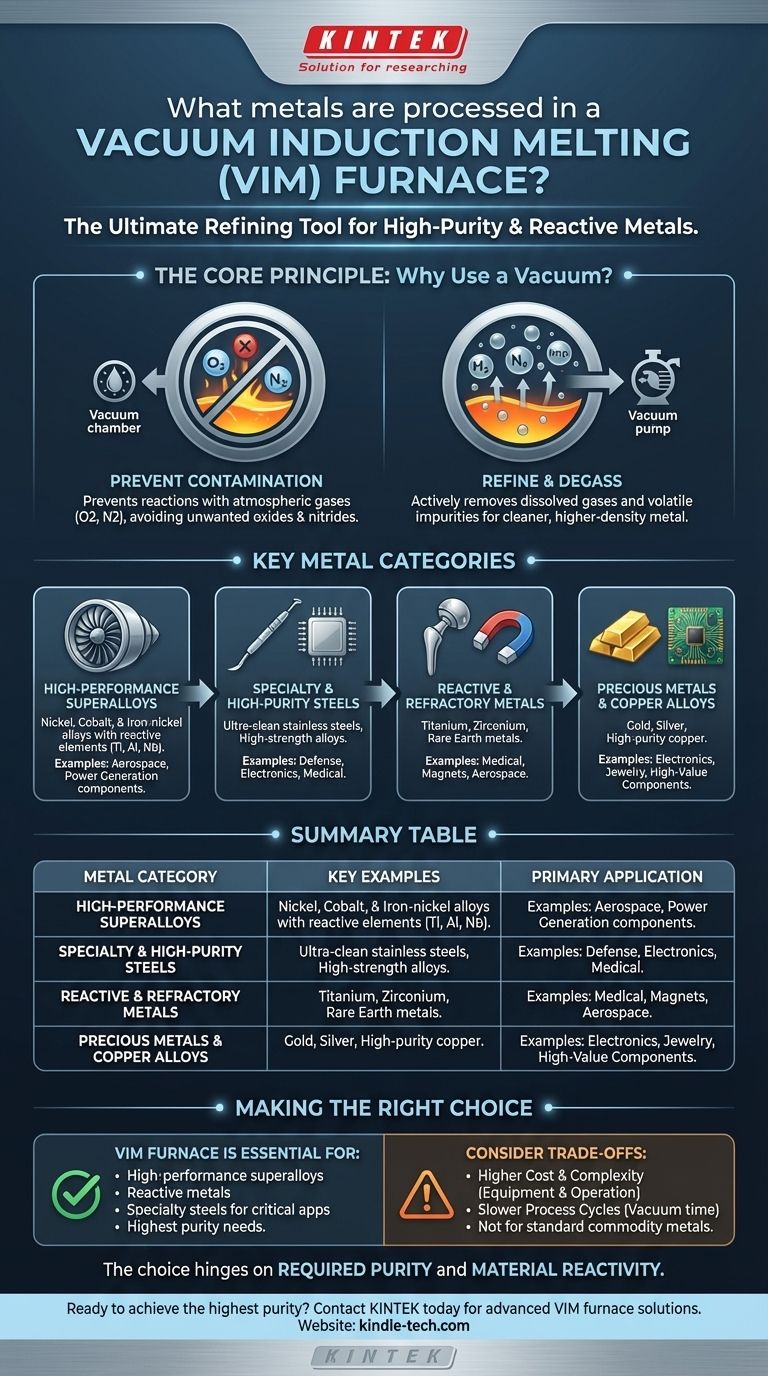

The Core Principle: Why Use a Vacuum?

The decision to use a VIM furnace is driven by the metallurgical needs of the material being processed. The vacuum environment provides fundamental advantages over melting in open air.

Preventing Oxidation and Contamination

At the extreme temperatures required for melting, many metals react aggressively with oxygen and nitrogen in the air.

This reaction forms unwanted oxides and nitrides within the metal structure. These impurities act as defects, compromising the material's strength, ductility, and overall performance. A vacuum removes these reactive gases, protecting the melt.

Refining and Degassing the Melt

A vacuum actively cleans the molten metal. The low-pressure environment helps pull dissolved gases, particularly hydrogen and nitrogen, out of the liquid.

Furthermore, it can boil off undesirable tramp elements with high vapor pressures. This refining process results in a cleaner, higher-density, and more reliable final product.

A Breakdown of Key Metal Categories

VIM furnaces are used for a specific range of materials where the benefits of a controlled atmosphere justify the cost and complexity of the process.

High-Performance Superalloys

This is a primary application for VIM furnaces. Nickel-based, cobalt-based, and iron-nickel alloys used in aerospace and power generation contain reactive elements like titanium, aluminum, and niobium that must be precisely controlled and protected from oxidation.

Specialty and High-Purity Steels

VIM is essential for producing ultra-clean steels. This includes stainless steels with very low carbon content, ultra-high-strength steels for defense applications, and precision alloys used in electronics, where even trace impurities can alter performance.

Reactive and Refractory Metals

Metals like titanium alloys, rare earth metals (e.g., for permanent magnets), and refractory metals are impossible to melt cleanly in an open-air furnace. They react so readily with oxygen that a vacuum or inert atmosphere is non-negotiable.

Precious Metals and Copper Alloys

While gold, silver, and copper can be melted in simpler furnaces, VIM is employed when the goal is maximum purity and recovery. The vacuum prevents any material loss to oxidation, which is a significant economic concern when working with precious metals.

Understanding the Trade-offs

A VIM furnace is a specialized tool, not a universal solution for all melting operations. Understanding its limitations is key to appreciating its purpose.

Cost and Complexity

VIM systems are significantly more expensive to purchase, operate, and maintain than standard air-melt induction furnaces due to the vacuum chamber, pumps, and sophisticated controls.

Slower Process Cycles

Achieving and maintaining a high vacuum adds considerable time to each melt cycle. This makes the process less suitable for high-volume, commodity-grade metal production where speed is a priority.

When a VIM Furnace is Overkill

For melting standard carbon steel, cast iron, or general-purpose aluminum and brass where minor inclusions and gas porosity are acceptable, a simpler and more economical air-melt furnace is the appropriate choice.

Making the Right Choice for Your Goal

The decision to use a VIM furnace hinges entirely on the required quality of the final material.

- If your primary focus is producing high-performance superalloys, titanium alloys, or specialty steels for critical applications: The VIM furnace is the essential tool for its purification and contamination control capabilities.

- If your primary focus is melting standard carbon steel, iron, or common non-ferrous alloys for general casting: A standard air-melt induction furnace is the more cost-effective and efficient choice.

- If your primary focus is refining precious metals to the highest purity or working with rare earth elements: A VIM furnace provides the controlled environment needed to prevent material loss and ensure metallurgical quality.

Ultimately, the choice of furnace is dictated by the metal's inherent reactivity and the non-negotiable purity requirements of the final product.

Summary Table:

| Metal Category | Key Examples | Primary Application |

|---|---|---|

| High-Performance Superalloys | Nickel-based, Cobalt-based alloys | Aerospace, Power Generation |

| Specialty & High-Purity Steels | Ultra-clean stainless steels, High-strength alloys | Defense, Electronics |

| Reactive & Refractory Metals | Titanium, Zirconium, Rare Earth metals | Medical, Magnets, Aerospace |

| Precious Metals & Copper Alloys | Gold, Silver, High-purity copper | Electronics, Jewelry, High-Value Components |

Need to achieve the highest purity for your critical metal components? KINTEK specializes in advanced vacuum induction melting furnaces designed for processing superalloys, reactive metals, and specialty steels. Our solutions ensure superior contamination control and precise chemical composition for your most demanding applications. Contact our experts today to discuss how our lab equipment can enhance your metallurgical processes!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- Does induction heating work with copper? Yes, with the right high-frequency equipment.

- What is the temperature range of an induction furnace? From 1250°C to Over 2000°C for Your Specific Application

- What is the process of melting in an induction furnace? Discover Efficient, Clean Metal Melting

- What is the function of a Vacuum Induction Melting (VIM) furnace in FeCrAl steel prep? Ensure Ultimate Alloy Purity

- What is the difference between an induction furnace and an arc furnace? Choosing the Right Melting Technology

- What is the role of an industrial vacuum induction furnace in melting 12% Cr martensitic steel? Pure & Tough Alloys

- What is the value of using a Small-Scale Laboratory Melting Furnace for R&D? Optimize Your Corrosion-Resistant Steels

- What is the basic lining of the induction furnace? The Engineered Core for Safe, Efficient Melting