Yes, high-fusing porcelain can be successfully repaired without distortion, but it requires a disciplined approach and a fundamental understanding of ceramic science. The key is not to re-fire the original porcelain at its maturation temperature, but to use a specialized, lower-fusing material for the addition. This allows the new material to fuse and glaze without causing the stable, foundational ceramic to slump or warp.

The core principle of any successful porcelain repair is that each subsequent firing must be conducted at a temperature lower than the previous one. Attempting to repair porcelain by firing it at its original high temperature will inevitably lead to distortion, ruining the restoration's form and fit.

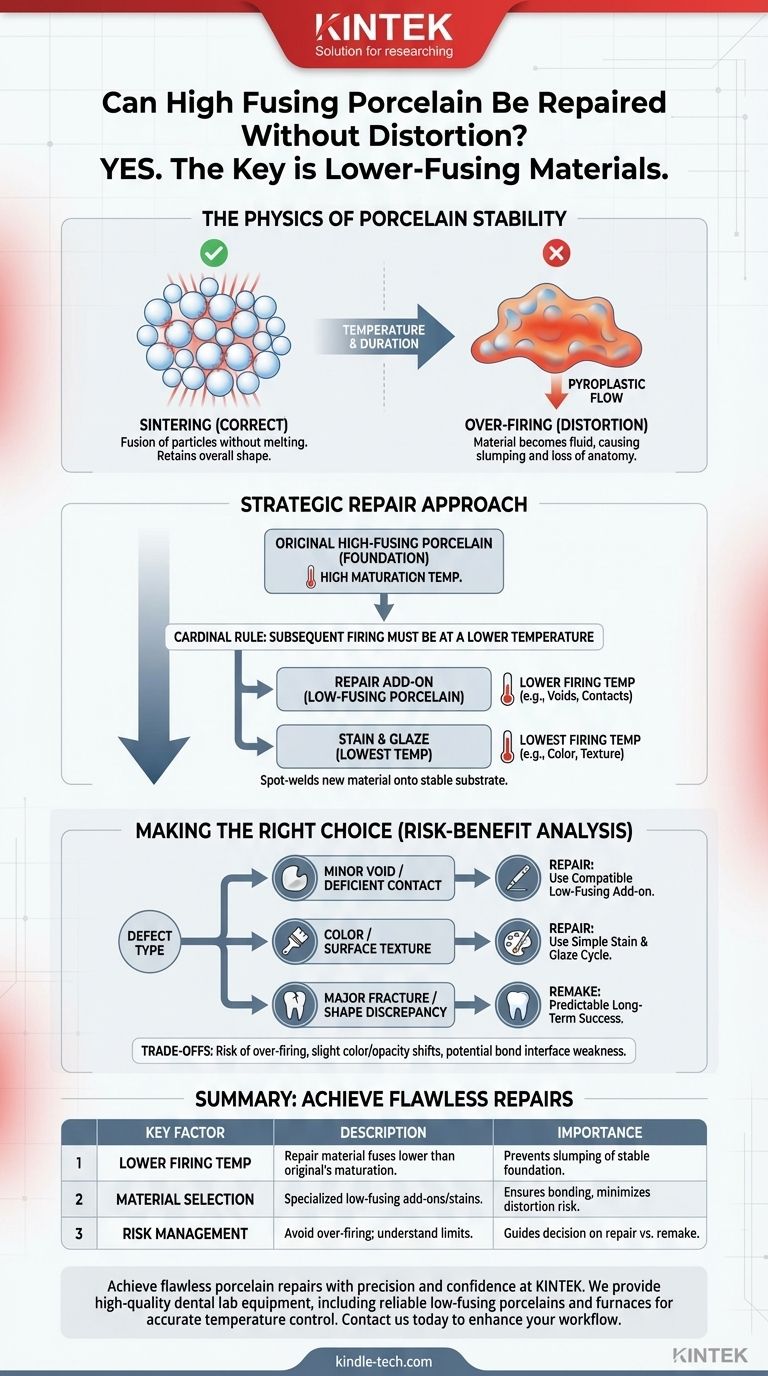

The Physics of Porcelain Stability

To understand how to repair porcelain, you must first understand how it's made. The process is not one of simple melting and solidifying like ice, but a more complex thermal process.

The Sintering Process

Dental porcelain is not melted into a liquid. Instead, it undergoes a process called sintering, where individual ceramic particles are heated until their surfaces begin to fuse together.

This densifies the material and reduces porosity, creating a strong, solid mass while largely retaining its overall shape.

The Role of Temperature

The firing temperature and duration are the most critical variables. The goal is to reach the ideal point of vitrification (the conversion into a glass-like substance) where the porcelain achieves maximum density and strength.

If this temperature is exceeded, or the hold time is too long, the porcelain will begin to flow like a thick liquid. This is the source of distortion, also known as slumping or pyroplastic flow, which causes the loss of anatomy, rounded margins, and a poor fit.

High-Fusing vs. Low-Fusing Porcelain

High-fusing porcelain, used for the main body or core of a restoration, is designed to be highly stable and withstand multiple subsequent firings. Its composition gives it a high sintering temperature.

Low-fusing "add-on" or "correction" porcelains are specifically engineered with a different chemical composition (more glass modifiers or "fluxes"). This allows them to sinter and glaze at a significantly lower temperature, making them ideal for repairs.

The Strategic Approach to Repair

A successful repair is a calculated procedure that respects the thermal properties of the original ceramic.

The Cardinal Rule: A Lower Firing Cycle

The repair porcelain must have a maturation temperature that is lower than the temperature used for the final glaze bake of the original restoration.

This ensures the heat is just enough to fuse the new material without re-activating the pyroplastic flow of the foundational porcelain. You are essentially "spot welding" the new material onto a stable substrate.

Selecting the Right Repair Material

Your choice of material is dictated by the nature of the repair. For small voids or contact adjustments, a specific low-fusing add-on porcelain that is compatible with your original ceramic system is the correct choice.

For minor surface texture or color adjustments, an even lower-firing stain and glaze application is sufficient. This involves the lowest temperatures and presents the least risk of distortion.

Understanding the Trade-offs and Risks

While repair is often possible, it is not without potential compromises. Being aware of them is crucial for managing expectations.

The Risk of Over-firing

The primary risk is accidentally over-firing the repair. This can happen if the wrong firing program is selected or if the furnace's thermocouple is inaccurate. The result will be distortion of the original restoration, which is often irreversible.

Challenges in Color and Opacity

Repeated firings, even at lower temperatures, can subtly alter the optical properties of the underlying porcelain. This can sometimes make achieving a perfect color match with the repair material challenging. The repaired area may appear slightly more opaque or have a different value.

Potential for a Weaker Bond

While the chemical bond between a modern repair porcelain and the original ceramic is very strong, the interface represents a transition zone. In areas of very high functional stress, this interface could theoretically be a point of weakness compared to a monolithic, unrepaired restoration.

Making the Right Choice for Your Restoration

Your decision to repair or remake should be based on a risk-benefit analysis for the specific defect.

- If your primary focus is correcting a minor void or deficient contact: Use a compatible, low-fusing add-on porcelain with a dedicated, lower-temperature firing program.

- If your primary focus is adjusting color or surface texture: A simple, low-temperature stain and glaze cycle is the safest and most effective method.

- If you are facing a major structural fracture or significant shape discrepancy: Remaking the restoration is almost always the most predictable path to ensuring long-term strength, aesthetics, and clinical success.

By respecting the thermal hierarchy of dental ceramics, you can perform precise repairs that save time and resources without compromising the integrity of the original work.

Summary Table:

| Key Factor | Description | Importance |

|---|---|---|

| Lower Firing Temperature | Repair material must fuse at a temperature lower than the original porcelain's maturation point. | Prevents slumping and warping of the stable foundation. |

| Material Selection | Use specialized low-fusing add-on porcelains or stains/glazes compatible with the original system. | Ensures proper bonding and minimizes risk of distortion. |

| Sintering Process | Understand that porcelain fuses via sintering, not melting, which maintains shape integrity when done correctly. | Foundation for applying correct thermal protocols. |

| Risk Management | Over-firing can cause irreversible distortion; repeated firings may affect color/opacity. | Guides decision-making on when to repair vs. remake. |

Achieve flawless porcelain repairs with precision and confidence. At KINTEK, we specialize in providing high-quality dental lab equipment and consumables, including reliable low-fusing porcelains and furnaces designed for accurate temperature control. Whether you're tackling minor adjustments or complex additions, our products help you maintain restoration integrity without distortion. Contact us today to enhance your ceramic workflow and ensure predictable, high-quality results for your dental restorations. Reach out via our contact form to discuss your specific needs!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How long should a porcelain ceramic crown last? Maximize Your Investment with Proper Care

- What are the disadvantages of all-ceramic restorations? Key Limitations for Long-Term Success

- What is a porcelain furnace? The Key to Creating Perfect Dental Restorations

- How do electronic controllers function in a furnace for sintering dental materials? The Key to Precision Sintering

- What is a burnout furnace used for in dentistry? Create Perfect Dental Crowns & Bridges

- What is dental ceramic used for? Restore Teeth with Aesthetic, Durable Crowns & Fillings

- What physical changes occur to ceramic materials like zirconia during sintering? Maximize Density and Strength

- Why is kaolin used for crown teeth? The Key Ingredient for Shaping Strong, Natural-Looking Porcelain