At its core, the single defining difference between soldering and brazing is temperature. Both processes join metals using a filler material without melting the base parts, but brazing occurs at high temperatures (above 450°C / 840°F) while soldering is a low-temperature process performed below this threshold. This fundamental distinction in heat directly impacts joint strength, material compatibility, and suitable applications.

Choosing between soldering and brazing is a trade-off between strength and sensitivity. Brazing creates exceptionally strong, structural bonds, while soldering's lower heat makes it the only viable option for delicate, temperature-sensitive components like electronics.

The Defining Factor: Temperature and Filler Metal

The entire classification of these two processes hinges on one internationally recognized temperature. This single variable dictates the type of filler metal used and the resulting characteristics of the joint.

The 450°C (840°F) Threshold

This specific temperature is the formal dividing line. Any process using a filler metal that melts below this point is classified as soldering. Any process using a filler metal that melts above it is classified as brazing.

Soldering: The Low-Temperature Process

Soldering uses filler metals, or solders, that are typically alloys of tin, lead, silver, or other low-melting-point elements. The goal is often to create an electrical connection rather than a high-strength mechanical bond.

Brazing: The High-Temperature Process

Brazing uses filler alloys with much higher melting points, often containing silver, copper, nickel, or aluminum. The greater heat involved facilitates a stronger metallurgical bond between the filler and the base metals through a process called capillary action.

Why This Difference Matters: Strength and Application

The significant gap in operating temperatures creates two very different tools for two very different sets of problems. One is built for strength, the other for delicacy.

Joint Strength: A Clear Distinction

Brazed joints are dramatically stronger than soldered joints. A properly brazed joint can be as strong, or even stronger, than the base metals it is connecting. This makes it suitable for structural applications that must bear significant stress or vibration.

In contrast, a soldered joint is comparatively weak. Its primary purpose is typically for adhesion and electrical conductivity, not mechanical load-bearing.

Common Applications for Soldering

The low heat of soldering makes it ideal for components that would be damaged by high temperatures. Its most common use is in electronics for attaching components to printed circuit boards (PCBs). It is also used in plumbing for joining copper pipes and in decorative arts like stained glass.

Common Applications for Brazing

Brazing's strength makes it a staple in industrial manufacturing. It is widely used in the automotive industry for components like radiators and air conditioning systems, in HVAC, and for joining parts in tools and heavy equipment.

Understanding the Trade-offs

Choosing a method isn't just about picking the strongest option. The high heat required for brazing introduces critical limitations that you must consider.

The Risk of Heat Damage

The primary advantage of soldering is also the primary drawback of brazing: heat. The high temperatures of brazing can easily damage or distort thin, delicate, or previously heat-treated base materials, making the process unsuitable for sensitive applications.

Process Complexity and Equipment

Soldering is generally a simpler process, often achievable with a basic soldering iron or torch. Brazing requires more precise temperature control and more powerful heat sources, which can increase complexity and cost.

Material Compatibility

While both can join dissimilar metals, brazing is generally more versatile. The high heat and specialized filler alloys allow for strong bonds between a very wide range of materials, such as steel to copper or tungsten carbide to steel.

Making the Right Choice for Your Application

Ultimately, the choice depends entirely on the demands of your specific project.

- If your primary focus is electrical conductivity or joining heat-sensitive components: Soldering is the correct choice due to its low-temperature application.

- If your primary focus is maximum joint strength for structural parts: Brazing is superior, creating a bond that is often as strong as the materials being joined.

- If your primary focus is joining dissimilar or high-strength metals: Brazing provides a more robust and reliable solution for challenging material combinations.

Understanding this fundamental trade-off between heat, strength, and component sensitivity is the key to selecting the right joining process for your work.

Summary Table:

| Feature | Soldering | Brazing |

|---|---|---|

| Process Temperature | Below 450°C (840°F) | Above 450°C (840°F) |

| Joint Strength | Lower (for adhesion/electrical) | High (structural, as strong as base metals) |

| Primary Applications | Electronics, plumbing, delicate components | Automotive, HVAC, heavy equipment |

| Heat Sensitivity | Ideal for heat-sensitive parts | Risk of damaging delicate materials |

Need expert advice for your metal joining applications? The right equipment is crucial for achieving perfect soldering or brazing results. KINTEK specializes in high-performance lab equipment and consumables for all your thermal processing needs. Our solutions ensure precise temperature control and reliable performance for both delicate electronic assemblies and robust industrial brazing.

Let our experts help you select the ideal equipment for your specific requirements.

Contact us today to discuss how KINTEK can enhance your laboratory's capabilities and efficiency!

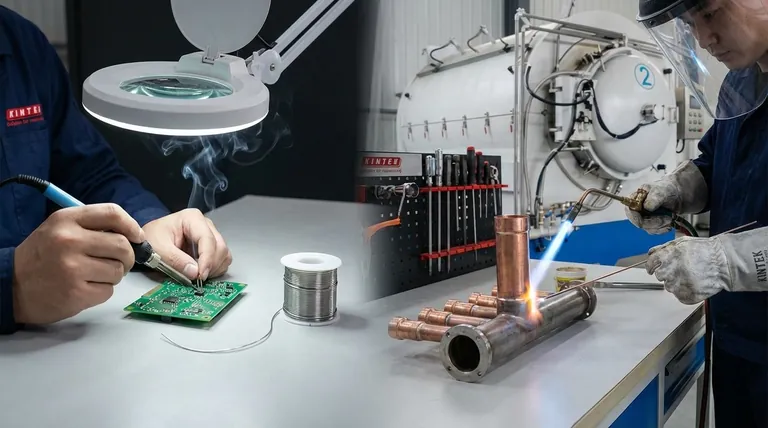

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- How is the greatest joint strength obtained in brazing? Master the 3 Keys to Superior Metallurgical Bonds