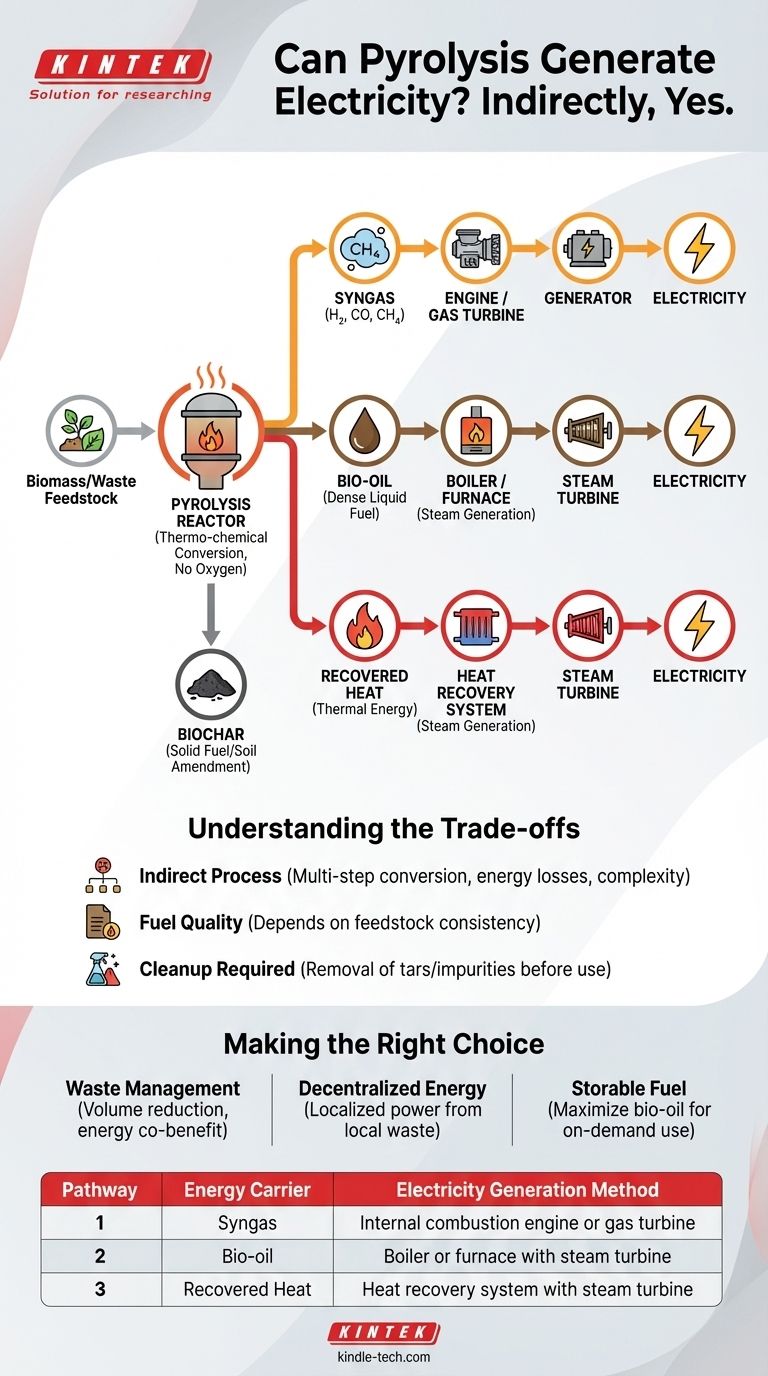

Yes, pyrolysis can be used to generate electricity, but it does so indirectly. The process itself doesn't produce an electrical current; instead, it converts biomass or waste into energy-dense fuels—specifically syngas and bio-oil—along with recoverable heat. These products are then used in conventional systems like engines or turbines to generate electricity.

The critical distinction to understand is that pyrolysis is not a direct power generation method. It is a thermo-chemical conversion process that transforms feedstock into valuable energy carriers, which subsequently fuel standard electricity generation equipment.

How Pyrolysis Creates Energy Carriers

Pyrolysis is the thermal decomposition of materials at elevated temperatures in the absence of oxygen. Rather than burning the material, this process breaks it down into more fundamental, energy-rich components.

The Key Output: Syngas

Syngas, or synthesis gas, is a flammable mixture of gases, primarily hydrogen, carbon monoxide, and methane. This gas can be piped directly from the pyrolysis reactor to be used as a fuel.

The Key Output: Bio-oil

Bio-oil (or pyrolysis oil) is a dark, dense liquid fuel. It is created by rapidly cooling the hot vapors produced during pyrolysis. It can be stored, transported, and used similarly to conventional fuel oils.

Other Valuable Outputs: Heat and Biochar

The pyrolysis process is exothermic, meaning it releases a significant amount of thermal energy (heat). This heat can be captured and utilized. Additionally, a solid, carbon-rich material called biochar is left behind, which can be used as a fuel or for soil amendment.

The Pathways from Pyrolysis to Electricity

Once the pyrolysis process has created these energy carriers, there are three primary pathways to convert their stored energy into electricity.

Pathway 1: Using Syngas in Engines or Turbines

The most common method is to use the syngas as fuel for an internal combustion engine or a gas turbine. This machinery is directly connected to a generator, which converts the mechanical energy of the spinning engine or turbine into electrical energy.

Pathway 2: Combusting Bio-oil for Power

Bio-oil can be used as a substitute for diesel or heating oil in a boiler or furnace. Burning the bio-oil heats water to create high-pressure steam, which then drives a steam turbine connected to a generator.

Pathway 3: Capturing Waste Heat for Steam Generation

The substantial amount of heat generated by the pyrolysis reactor itself can be captured by a heat recovery system. This heat can boil water to power a steam turbine and generator, adding another layer of energy efficiency to the overall system.

Understanding the Trade-offs

While powerful, using pyrolysis for electricity generation is a multi-step process that involves important considerations and potential challenges.

It Is an Indirect Process

Unlike a solar panel or a wind turbine, pyrolysis requires multiple stages of conversion (feedstock to fuel, then fuel to electricity). Each stage introduces potential energy losses and requires additional equipment, increasing complexity and capital cost.

Fuel Quality Depends on Feedstock

The composition and quality of the syngas and bio-oil depend heavily on the initial material being processed. Inconsistent waste streams can lead to variable fuel quality, which can affect the performance and reliability of engines and turbines.

Gas and Oil Cleanup is Often Required

Raw syngas and bio-oil often contain tars, particulates, and other impurities that can damage downstream equipment. Therefore, a gas or oil cleanup and upgrading phase is typically necessary, adding another step and cost to the overall process.

Making the Right Choice for Your Goal

Understanding pyrolysis as a flexible conversion technology allows you to apply it effectively based on your specific objective.

- If your primary focus is waste management: Pyrolysis is an excellent technology for drastically reducing waste volume while creating valuable energy products as a co-benefit.

- If your primary focus is decentralized energy: Small-scale systems using the produced syngas to power an engine-generator set can provide reliable, localized power from local waste or biomass.

- If your primary focus is creating storable fuel: The process can be optimized to maximize bio-oil production, creating a liquid fuel that can be stored and used for power generation on demand.

Ultimately, pyrolysis serves as a critical bridge, transforming low-value materials into high-value fuels that integrate directly with established power generation technologies.

Summary Table:

| Pathway | Energy Carrier | Electricity Generation Method |

|---|---|---|

| 1 | Syngas | Internal combustion engine or gas turbine |

| 2 | Bio-oil | Boiler or furnace with steam turbine |

| 3 | Recovered Heat | Heat recovery system with steam turbine |

Ready to harness the power of pyrolysis for your energy needs? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're exploring waste-to-energy solutions or optimizing biofuel production, our expertise can help you achieve efficient and sustainable results. Contact us today to discuss how our solutions can support your laboratory's innovation in renewable energy!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

People Also Ask

- Can you extract THC without heat? Yes, and here’s how to preserve terpenes and potency.

- What metals can you blacksmith with? Discover Forgeable Metals for Every Project

- How does temperature affect pyrolysis? Master Product Yields from Biochar to Syngas

- What are the applications of additive manufacturing in dentistry? Unlock Faster, More Precise Patient Care

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the operating pressure for a filter press? Master the Pressure Curve for Optimal Dewatering

- How much pressure is required in DC sputtering? Optimize Your Thin-Film Deposition Process

- What temperature do you need to braze copper? Master the Perfect Heat for Strong, Leak-Proof Joints