Yes, you can absolutely anneal a metal multiple times. In fact, it is a standard and often necessary practice in many forms of metalworking. Each time a metal is bent, hammered, or stretched—a process known as work hardening—it becomes harder, more brittle, and more resistant to further shaping. Annealing reverses this effect, restoring the metal's ductility and allowing you to continue working with it.

The ability to anneal repeatedly is fundamental to complex metal forming. However, the critical factor is not if you can do it multiple times, but how you control the process each time to avoid degrading the material's structural integrity.

Why Multiple Annealing Cycles Are Necessary

Understanding Work Hardening

When you mechanically work a metal, you are deforming its internal crystal structure. The microscopic grains that make up the metal become stressed, elongated, and entangled.

This realignment of the grain structure makes the metal stronger but significantly reduces its ability to stretch or bend without cracking. Eventually, the metal will become so brittle that any further work will cause it to fracture.

The Goal: Restoring Ductility

Annealing is the solution to work hardening. By heating the metal to a specific temperature (its recrystallization temperature), you give the atoms enough energy to rearrange themselves into new, strain-free grains.

This process, called recrystallization, effectively resets the metal's internal structure, relieving the built-up stress and making it soft and ductile again. This allows for subsequent rounds of shaping and forming.

A Practical Analogy: Bending a Paperclip

Think of bending a paperclip back and forth. The first few bends are easy. Soon, the bend point becomes stiff and hard. If you continue, it snaps.

That stiff point is the work-hardened zone. If you could anneal the paperclip (without melting it), you could restore its original softness and continue bending it.

The Mechanics of a Proper Annealing Cycle

The Three Key Stages

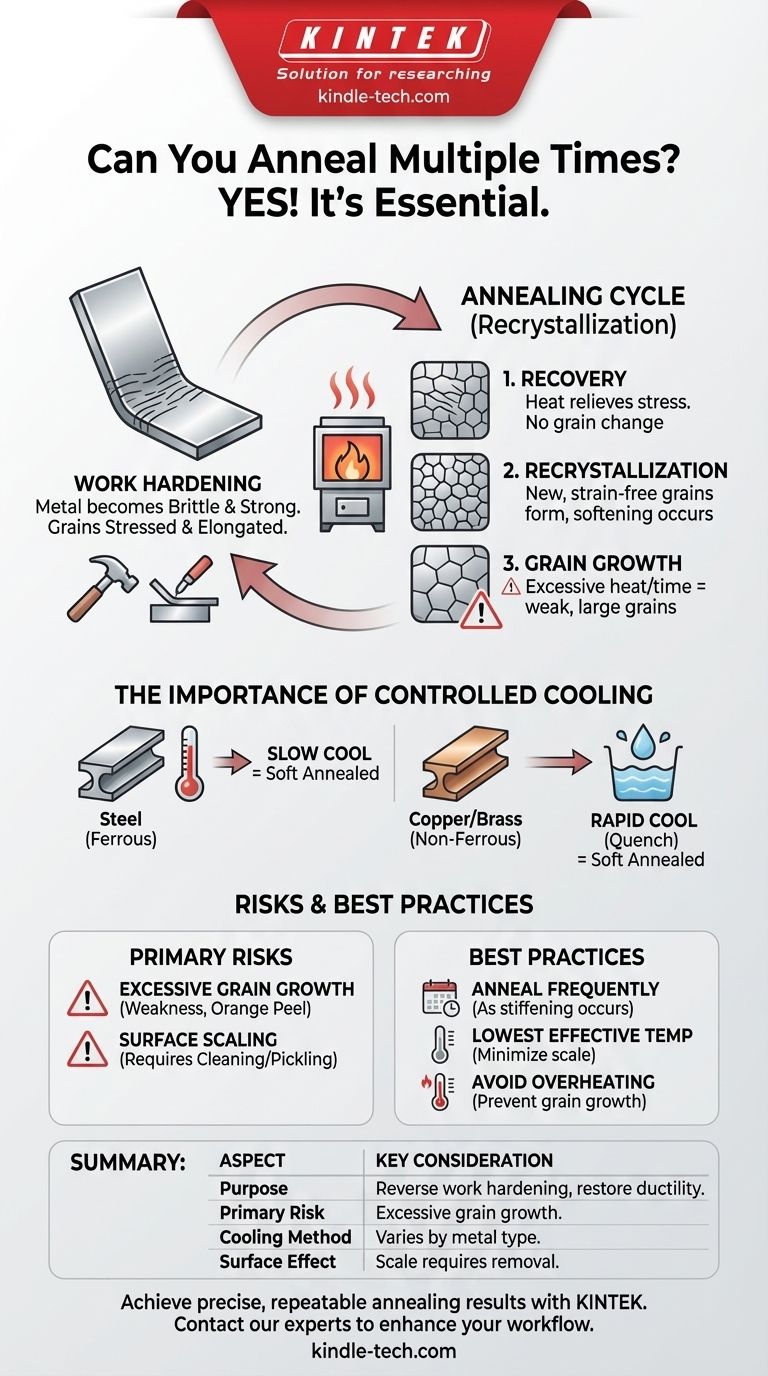

Every annealing cycle consists of three phases, and understanding them is key to controlling the outcome.

- Recovery: As you begin to heat the metal, it first relieves some internal stress without changing the grain structure.

- Recrystallization: At the correct temperature, new, stress-free grains begin to form and replace the old, deformed ones. This is the "softening" stage.

- Grain Growth: If the metal is held at the annealing temperature for too long, or heated to too high a temperature, the new grains will start to merge and grow larger.

The Importance of Controlled Cooling

The rate at which you cool the metal is just as important as the heating.

For many non-ferrous metals like copper, brass, and sterling silver, you can cool them rapidly by quenching in water. This locks in the soft, annealed state.

For most steels, however, rapid cooling (quenching) will have the opposite effect—it will harden them. Steel must be cooled very slowly to achieve a soft, annealed state.

Understanding the Trade-offs and Risks

The Danger of Excessive Grain Growth

This is the primary risk of improper or excessive annealing. While you want new grains to form, allowing them to grow too large will weaken the material.

Overly large grains can lead to a rough surface texture known as an "orange peel" effect when the metal is bent. More critically, it can reduce the metal's overall strength and toughness.

The Impact of Overheating

Heating a metal far beyond its recrystallization temperature can cause rapid and excessive grain growth. If you heat it too close to its melting point, you risk permanently damaging or destroying the piece.

Surface Oxidation and Scaling

Each time you heat a metal in the presence of oxygen, a layer of oxide, or "scale," will form on the surface.

This scale must typically be removed, often with an acid bath (pickling), before continuing work. Repeated cycles of scaling and pickling can lead to a minor loss of material over time.

How to Apply This to Your Project

Your approach to annealing should be dictated by the material you are using and the demands of your project.

- If your primary focus is significant shaping (e.g., raising a vessel): Plan to anneal frequently, as soon as you feel the metal begin to stiffen and resist your tools. This prevents the buildup of excessive stress.

- If your primary focus is preserving fine surface detail: Use the lowest effective temperature and shortest time required for a successful anneal. This will minimize the formation of surface scale.

- If your primary focus is preventing weakness in the final piece: Avoid overheating and holding the piece at temperature for longer than necessary. Your goal is recrystallization, not excessive grain growth.

Ultimately, viewing annealing not as a single event but as a repeatable and essential step in your workflow is key to achieving complex and successful results in metalwork.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Purpose | Reverse work hardening, restore ductility for further shaping. |

| Primary Risk | Excessive grain growth from overheating or holding too long. |

| Cooling Method | Varies by metal (e.g., quench non-ferrous; slow cool steel). |

| Surface Effect | Scale formation requires removal (e.g., pickling). |

Achieve precise, repeatable annealing results with KINTEK.

Whether you are shaping complex components or need to restore ductility in precious metals, controlling the annealing cycle is critical to your success. KINTEK specializes in the lab equipment and consumables that laboratories rely on for consistent, high-quality heat treatment processes.

Contact our experts today to discuss how our solutions can enhance your metalworking workflow and ensure material integrity through every cycle.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries