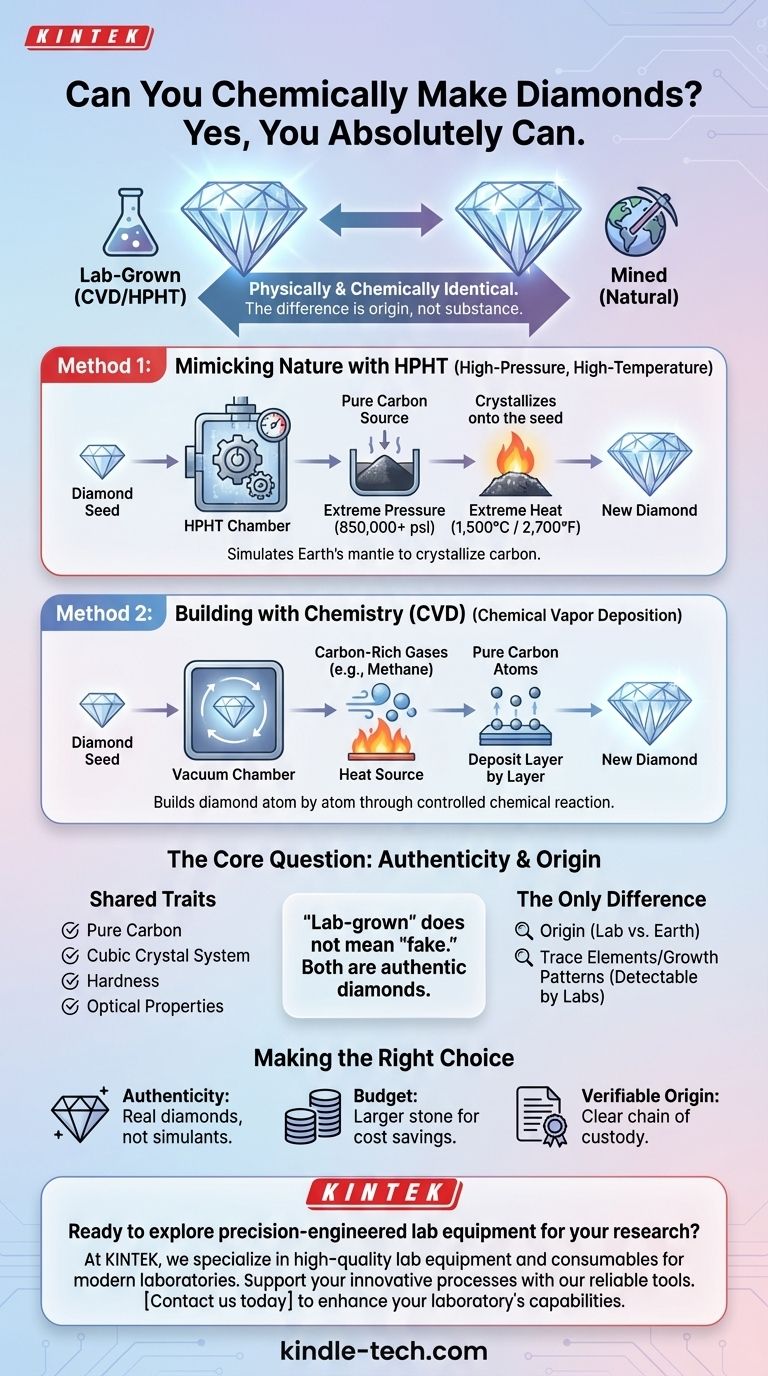

Yes, you absolutely can. Diamonds can be created through a purely chemical process known as Chemical Vapor Deposition (CVD). This method, along with a high-pressure technique called HPHT, produces diamonds that are physically and chemically identical to those formed in the earth.

The core takeaway is that "lab-grown" does not mean "fake." Whether made through the high-pressure HPHT method or the chemical CVD method, the resulting gems are authentic diamonds, indistinguishable from their mined counterparts without specialized equipment.

The Two Paths to a Lab-Grown Diamond

Creating a diamond in a laboratory involves replicating the conditions under which carbon crystallizes into its strongest form. Scientists have perfected two distinct and effective methods to achieve this: High-Pressure, High-Temperature (HPHT) and Chemical Vapor Deposition (CVD).

One method mimics nature's brute force, while the other builds the diamond atom by atom.

Method 1: Mimicking Nature with HPHT

HPHT stands for High-Pressure, High-Temperature. This was the original method developed to grow diamonds and it works by directly simulating the natural diamond-forming process of the Earth's mantle.

The HPHT Process

A small, natural diamond fragment, known as a diamond seed, is placed into a chamber with a source of pure carbon. This chamber is then subjected to immense pressures (over 850,000 pounds per square inch) and extreme heat (around 1,500°C or 2,700°F).

Under these conditions, the carbon source melts and crystallizes onto the diamond seed, growing a new, larger, and complete diamond.

Method 2: Building Diamonds with Chemistry (CVD)

CVD, or Chemical Vapor Deposition, is the more explicitly "chemical" process. Instead of immense pressure, this method uses a controlled chemical reaction to build the diamond.

The CVD Process

The process starts with a diamond seed placed inside a sealed vacuum chamber. The chamber is then filled with carbon-rich gases, such as methane.

This gas is heated to a high temperature, causing the carbon atoms to separate from their gas molecules. These pure carbon atoms then rain down and deposit onto the diamond seed, building up the crystal structure layer by layer.

The Core Question: Authenticity and Origin

A common point of confusion is whether lab-grown diamonds are "real." The distinction is one of origin, not substance.

Chemical and Physical Identity

Both CVD and HPHT methods produce a stone that is pure carbon crystallized in an isometric cubic system. This means it has the same chemical composition, optical properties, and physical hardness as a diamond mined from the Earth.

The Only True Difference

The only thing that separates a lab-grown diamond from a natural one is its point of origin. Advanced gemological labs can detect minute differences in growth patterns and trace elements to determine whether a diamond was formed in a lab or deep underground.

Making the Right Choice for Your Goal

Understanding how lab diamonds are made helps clarify their value and place in the market.

- If your primary focus is authenticity: You can be confident that diamonds created via CVD or HPHT are real diamonds, not simulants like cubic zirconia or moissanite.

- If your primary focus is a larger stone for your budget: Lab-grown diamonds typically offer a significant cost savings compared to mined diamonds of the same size and quality.

- If your primary focus is a verifiable origin: The controlled, documented process of lab creation provides a clear chain of custody that is often difficult to achieve with mined gems.

Ultimately, technology now allows us to create one of nature's most coveted materials in a controlled, scientific environment.

Summary Table:

| Method | Process | Key Feature |

|---|---|---|

| HPHT (High-Pressure High-Temperature) | Mimics Earth's mantle using extreme pressure & heat on a carbon source. | Simulates natural diamond formation. |

| CVD (Chemical Vapor Deposition) | Uses a chemical reaction in a vacuum chamber to deposit carbon layer by layer. | Builds diamond atom by atom with precision. |

Ready to explore precision-engineered lab equipment for your research? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to meet the rigorous demands of modern laboratories. Whether you're advancing materials science or developing new technologies, our reliable tools support your innovative processes. Contact us today to discover how KINTEK can enhance your laboratory's capabilities and efficiency.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance