No, not all lab-grown diamonds are made using the CVD method. While it is a prominent and increasingly popular technique, it is one of two primary methods used to create gem-quality diamonds in a laboratory. The other foundational method is known as High Pressure/High Temperature (HPHT).

The lab-grown diamond market is fundamentally built on two distinct technologies: Chemical Vapor Deposition (CVD) and High Pressure/High Temperature (HPHT). Both produce a real diamond, but their different approaches to creation can influence the stone's characteristics and the challenges faced during production.

The Two Pillars of Diamond Creation

While obscure industrial methods like detonation exist, the world of gem-quality lab diamonds revolves exclusively around two sophisticated processes. Understanding them is key to understanding the final product.

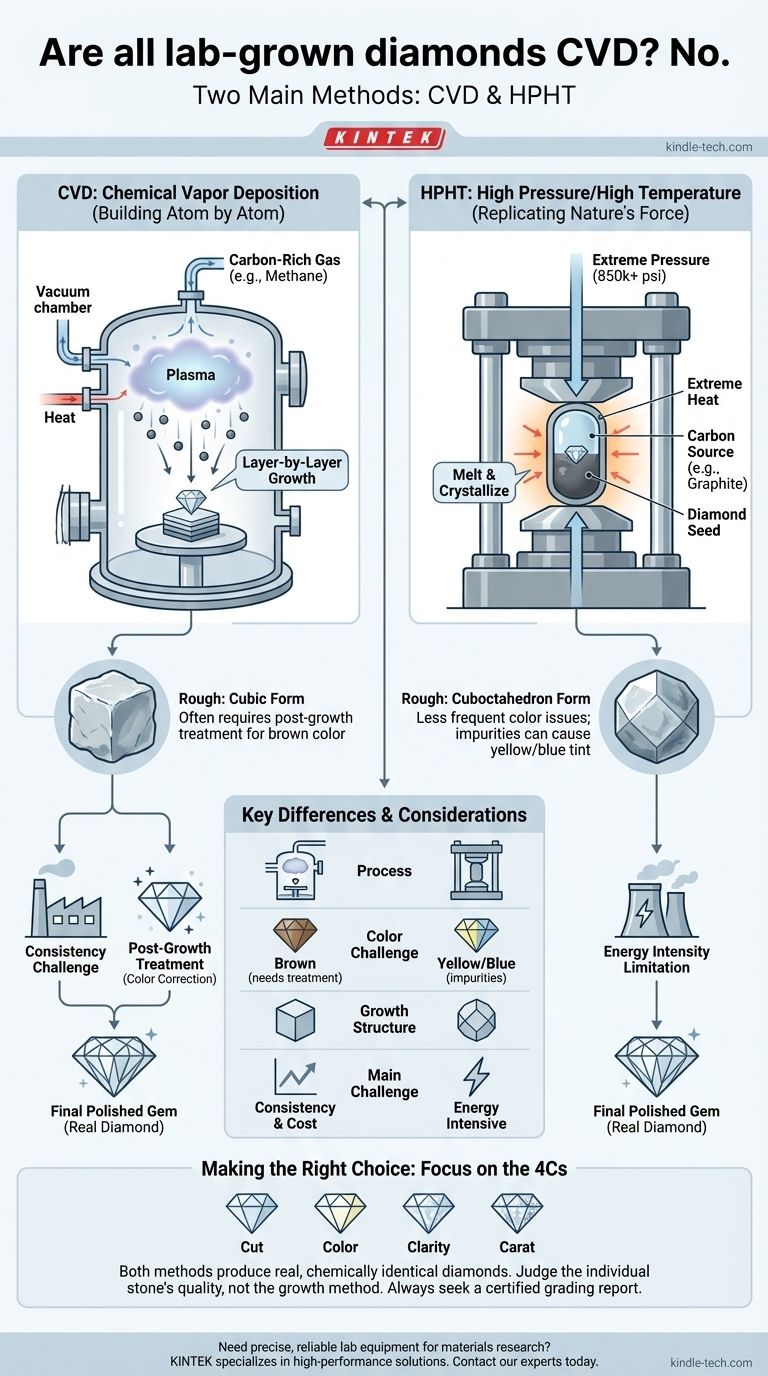

The CVD Method: Building Atom by Atom

Chemical Vapor Deposition (CVD) is an additive process. It begins with a tiny, flat diamond "seed."

This seed is placed into a vacuum chamber which is then filled with a carbon-rich gas, like methane. The chamber is heated to extreme temperatures, causing the gas to ionize and break apart, releasing its carbon atoms.

These individual carbon atoms then "rain" down and attach to the diamond seed, building up the crystal one layer at a time. Over several weeks, this process results in a fully formed, gem-quality diamond.

The HPHT Method: Replicating Nature's Force

High Pressure/High Temperature (HPHT) is the original method for creating lab diamonds and is designed to mimic the conditions deep within the Earth's mantle.

In this process, a small diamond seed is placed into a chamber along with a source of pure carbon, such as graphite. This chamber is then subjected to immense pressure (over 850,000 pounds per square inch) and incredibly high temperatures.

This extreme environment forces the carbon source to melt and crystallize around the diamond seed, forming a new, larger diamond.

How This Affects the Final Gemstone

To the naked eye, a high-quality CVD and HPHT diamond are indistinguishable from each other and from a mined diamond. However, gemological labs can identify subtle differences in their growth structure and trace elements.

The Challenge of Color

One of the most significant practical differences emerges in the color of the stones as they are grown.

CVD diamonds, especially when grown quickly, often develop a brown color. To correct this, many CVD diamonds undergo a secondary HPHT treatment after they are grown to remove the brown hue and improve their color grade.

HPHT diamonds do not typically have a brown color issue. However, if any impurities like nitrogen or boron accidentally enter the growth chamber, they can result in a stone with a slight yellow or blue tint.

Growth Structure and Inclusions

The two methods produce diamonds with different crystal shapes. CVD diamonds tend to grow in a cubic form, while HPHT diamonds naturally form a cuboctahedron shape.

These growth patterns are cut away during the faceting process, so they are not visible in the final polished gemstone. They are, however, key identifiers for gemologists.

Understanding the Trade-offs

Neither method is universally superior; each comes with its own set of manufacturing challenges and advantages that influence the market.

The CVD Challenge: Consistency

Manufacturers of CVD diamonds face significant challenges in maintaining a perfectly stable growing environment. Any direct air leakage or instability in the system can disrupt growth or introduce imperfections.

The frequent need for post-growth color treatment is a major consideration. This extra step adds to the production time and cost, impacting the manufacturer's profitability.

The HPHT Limitation: Energy Intensity

The HPHT process requires an enormous amount of energy to maintain the extreme pressure and temperature needed for diamond formation. This makes it a very power-intensive and expensive operation.

Historically, HPHT was also more limited in its ability to produce large, high-quality colorless diamonds, though significant technological advancements have largely overcome this barrier.

Making the Right Choice for Your Goal

Ultimately, both CVD and HPHT produce real diamonds that are physically and chemically identical to their mined counterparts. The choice between them is less about "good" vs. "bad" and more about understanding the nuances of the individual stone before you.

- If your primary focus is the best quality for your budget: Judge the diamond on its individual merits—the 4Cs (Cut, Color, Clarity, Carat)—not its growth method. A grading report from a reputable lab is your most important tool.

- If your primary focus is avoiding post-growth treatments: An HPHT diamond may be a more likely candidate, as they less frequently require color correction. Always ask for the diamond's certification, which will disclose any treatments.

- If your primary focus is the technology itself: Choose the story that resonates with you—the "atomic layering" of CVD or the "Earth simulation" of HPHT.

A certified lab-grown diamond is a remarkable piece of modern technology, making its growth method a fascinating detail rather than a defining factor of its beauty or value.

Summary Table:

| Method | Process Description | Key Characteristics |

|---|---|---|

| CVD (Chemical Vapor Deposition) | Carbon atoms build on a seed in a vacuum chamber. | Often requires post-growth treatment to correct brown color; grows in a cubic shape. |

| HPHT (High Pressure/High Temperature) | Mimics Earth's mantle with extreme heat and pressure. | Less frequent color treatment; energy-intensive; grows in a cuboctahedron shape. |

Need precise, reliable equipment for materials research or laboratory analysis? KINTEK specializes in high-performance lab equipment and consumables, serving a wide range of scientific and industrial needs. Whether your work involves advanced materials synthesis or precise measurement, our solutions are designed to enhance your efficiency and accuracy. Contact our experts today to find the perfect equipment for your laboratory's unique challenges.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- CVD Diamond for Thermal Management Applications

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How does Microwave Plasma Chemical Vapour Deposition (MPCVD) work? Your Guide to High-Purity Diamond Film Growth

- What are the advantages of microwave plasma? Faster, Purer Processing for Demanding Applications

- What are the characteristics and applications of MPCVD? Discover the Secret to High-Purity Lab-Grown Diamonds

- Can I buy lab diamonds? Your Guide to Modern, Ethical, and Affordable Diamonds

- What is the difference between RF and microwave plasma? Choose the Right Plasma for Your Process

- How are lab-grown diamonds created? Discover the HPHT and CVD Manufacturing Process

- Which is better lab grown or natural diamond? A Clear Guide to Choosing Your Perfect Stone

- What do you need to grow lab diamonds? Carbon, Seed, and Immense Energy Explained