Yes, a muffle furnace must be properly vented. This is not merely a recommendation but a critical requirement for safe operation, equipment longevity, and the integrity of your work. The venting system is designed to actively remove potentially hazardous or corrosive fumes, vapors, and gases that are released from materials during the high-temperature heating process.

Venting a muffle furnace is a non-negotiable operational step. It serves two primary, equally important functions: protecting the operator from potentially toxic fumes and protecting the furnace's internal components from the corrosive byproducts of the heating process itself.

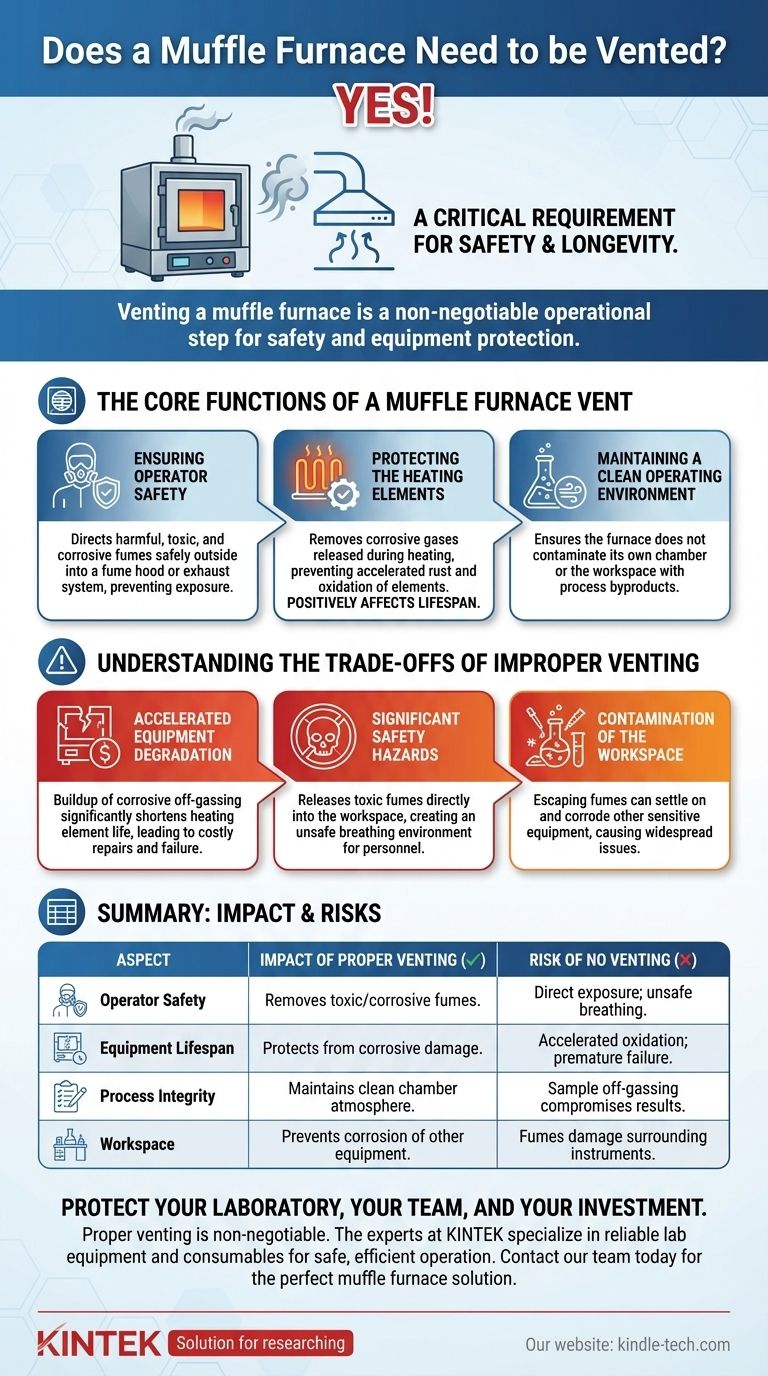

The Core Functions of a Muffle Furnace Vent

Understanding why venting is essential involves looking at its impact on safety, the equipment, and the surrounding environment.

Ensuring Operator Safety

Many processes performed in a muffle furnace, such as ashing organic matter or heat-treating materials with coatings, release fumes. These byproducts can be toxic, corrosive, or create an oxygen-deficient atmosphere if allowed to accumulate in the workspace.

A proper vent directs these harmful emissions safely outside, typically into a laboratory fume hood or a dedicated exhaust system.

Protecting the Heating Elements

The gases and vapors released from samples at high temperatures can be highly corrosive. If these byproducts are not removed, they will remain trapped inside the furnace chamber.

This corrosive atmosphere directly attacks the electric heating elements, causing them to rust and oxidize at an accelerated rate. As stated in technical documentation, venting is a direct factor that positively affects the lifespan of the elements.

Maintaining a Clean Operating Environment

A muffle furnace is designed to operate in an environment free of corrosive gases and flammable materials. The venting system is crucial for ensuring the furnace does not contaminate its own operating environment with the very substances it is designed to be protected from.

Understanding the Trade-offs of Improper Venting

Failing to vent a muffle furnace is not a cost-saving measure; it's a decision that introduces significant risks and hidden costs.

Accelerated Equipment Degradation

The most immediate consequence of not venting is damage to the furnace itself. The buildup of corrosive off-gassing will significantly shorten the life of the heating elements, leading to premature failure and costly repairs.

Significant Safety Hazards

Without venting, you are releasing all process fumes directly into your workspace. This exposes personnel to potentially toxic chemicals and creates an unsafe breathing environment, which is an unacceptable risk in any professional setting.

Contamination of the Workspace

Fumes that escape the furnace can settle on and corrode other sensitive equipment in the room. This can lead to widespread equipment issues far beyond the furnace itself.

Making the Right Choice for Your Application

Implementing a proper venting strategy is straightforward and essential for achieving your goals.

- If your primary focus is operator safety: The non-negotiable first step is to ensure all fumes are actively ducted from the furnace's vent port to an external exhaust system, like a fume hood.

- If your primary focus is equipment longevity: Consistently using the furnace's air vent prevents the buildup of corrosive gases, directly protecting the heating elements from oxidation and maximizing the unit's service life.

- If your primary focus is process accuracy: Proper venting ensures that off-gassing from your sample does not create an unintended and uncontrolled atmosphere within the chamber that could compromise your results.

Properly venting your muffle furnace is the single most important step for ensuring safe, reliable, and long-lasting operation.

Summary Table:

| Aspect | Impact of Proper Venting | Risk of No Venting |

|---|---|---|

| Operator Safety | Removes toxic/corrosive fumes from the workspace. | Direct exposure to hazardous fumes; unsafe breathing environment. |

| Equipment Lifespan | Protects heating elements from corrosive damage. | Accelerated oxidation and premature failure of elements. |

| Process Integrity | Maintains a clean, controlled chamber atmosphere. | Sample off-gassing can contaminate and compromise results. |

| Workspace | Prevents corrosion of other sensitive lab equipment. | Fumes can settle and damage surrounding instruments. |

Protect your laboratory, your team, and your investment. Proper venting is non-negotiable for safe and effective muffle furnace operation. The experts at KINTEK can help you select the right furnace and ensure it is integrated with a proper venting solution for your specific application.

We specialize in supplying reliable lab equipment and consumables, ensuring your laboratory operates safely and efficiently.

Contact our team today to discuss your needs and find the perfect muffle furnace solution for your lab.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role do High-Temperature Muffle Furnaces play in metal oxide precursor pre-treatment? Ensure Structural Integrity

- What is the role of a high-temperature box furnace in Si-doped TiO2 preparation? Precision for Photocatalysis

- Which of the following are the important temperature controls used in sintering furnace? Mastering Precise Thermal Profiles for Superior Materials

- What is the heat treatment process for steel? A Guide to Controlling Hardness, Toughness, and Performance

- What is the function of an external heating high-temperature furnace in SCWG? Optimize Your Biomass Gasification Research

- What is the function of industrial box resistance furnaces in 3D printing post-processing? Optimize Metal AM Parts

- How are high-temperature furnaces used to evaluate adsorbent stability? Key Testing for Industrial Carbon Capture

- What is the role of a laboratory oven in Carbon Paper catalyst preparation? Stabilize Nickel Precursors Effectively