Yes, gold absolutely melts in a furnace, provided the furnace is designed to reach and maintain the necessary temperature. Gold's melting point is 1,064°C (or 1,948°F), a temperature well within the capabilities of specialized metallurgical furnaces used for melting various ferrous and non-ferrous metals. The key is not just having a heat source, but having the correct type of equipment for a controlled and clean melt.

The question isn't whether a furnace can melt gold, but rather which type of furnace is appropriate for the task. Specialized equipment like electric induction or muffle furnaces are standard for melting precious metals, ensuring efficiency, purity, and control.

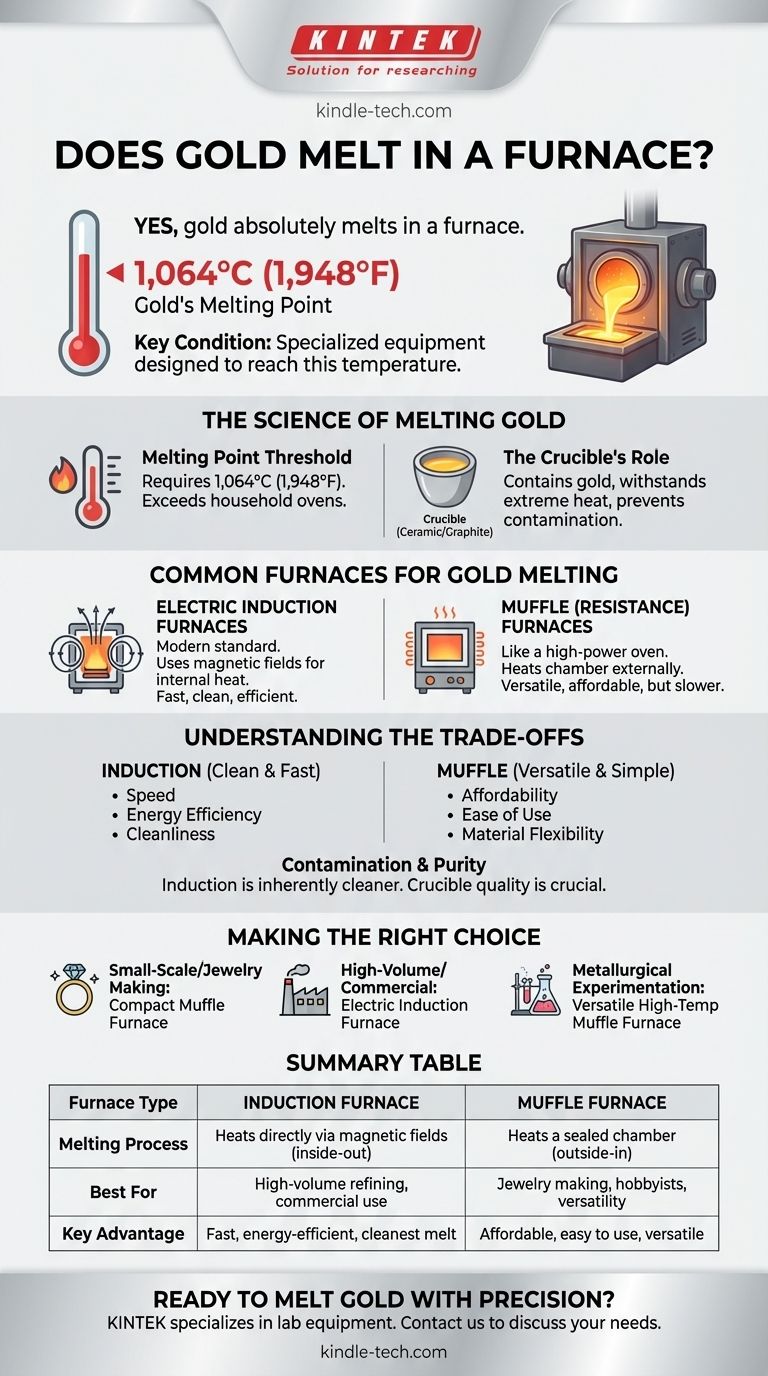

The Science of Melting Gold

To melt gold, you must overcome its physical properties with a specific amount of thermal energy. This requires more than just high heat; it requires the right application of that heat.

Gold's Melting Point: The Critical Threshold

The definitive temperature for melting pure gold is 1,064 degrees Celsius (1,948 degrees Fahrenheit). Any furnace used for this purpose must be able to safely exceed this temperature and hold it consistently.

This temperature is significantly higher than what a household oven or a standard pottery kiln can achieve, which is why specialized equipment is non-negotiable.

The Role of the Crucible

Gold is not placed directly into the furnace. It is contained within a crucible, a cup made from materials like graphite or ceramic that can withstand extreme temperatures without cracking or reacting with the molten gold.

The furnace heats the crucible, and the crucible, in turn, transfers that heat to melt the gold inside. The quality of the crucible is critical for preventing contamination of the precious metal.

Common Furnaces for Gold Melting

While several furnace types exist, two are predominantly used for melting gold due to their precision and efficiency.

Electric Induction Furnaces

An electric induction furnace is the modern standard for melting precious metals, including gold and silver. It does not use external heating elements.

Instead, it uses powerful alternating magnetic fields to induce an electric current directly within the gold itself. This internal resistance generates rapid, clean, and highly efficient heat from the inside out.

Muffle (Resistance) Furnaces

A muffle furnace is a type of resistance furnace that works more like a conventional high-power oven. It has a sealed chamber (the "muffle") that is heated by external electric coils.

The heat radiates throughout the chamber, heating the crucible and its contents. While often slower than induction furnaces, they are highly effective and versatile, capable of melting a wide range of metals from aluminum to platinum group elements.

Understanding the Trade-offs

Choosing between furnace types involves balancing speed, purity, and scale. No single solution is perfect for every scenario.

Induction vs. Muffle: The Core Differences

Induction furnaces are faster, more energy-efficient, and promote a natural stirring action in the molten metal, which can result in a more homogenous alloy. Their clean heating process minimizes contamination.

Muffle furnaces are generally simpler in design and can be more affordable for smaller-scale operations. They are extremely versatile for different materials but can be slower to reach temperature and less energy-efficient.

Contamination and Purity

Purity is paramount when working with gold. Induction heating is inherently cleaner because the heat is generated within the metal itself, reducing exposure to atmospheric contaminants or byproducts from fuel combustion.

In any furnace, using a high-quality, properly prepared crucible is essential to prevent impurities from leaching into the molten gold.

Making the Right Choice for Your Goal

Your specific objective determines which furnace is the most logical investment.

- If your primary focus is small-scale jewelry making or hobbyist refining: A compact electric muffle furnace often provides the best balance of affordability, ease of use, and sufficient temperature control.

- If your primary focus is high-volume commercial melting or high-purity refining: An electric induction furnace is the industry standard for its unmatched speed, energy efficiency, and clean melting process.

- If your goal is metallurgical experimentation with various metals: A versatile, high-temperature muffle furnace offers the flexibility to melt not just gold, but also metals with higher melting points like copper or even platinum.

Ultimately, selecting the correct furnace is about matching the tool's capabilities to the specific demands of your project.

Summary Table:

| Furnace Type | Melting Process | Best For | Key Advantage |

|---|---|---|---|

| Induction Furnace | Heats gold directly using magnetic fields (inside-out) | High-volume refining, commercial use | Fast, energy-efficient, cleanest melt |

| Muffle Furnace | Heats a sealed chamber (outside-in) | Jewelry making, hobbyists, versatility | Affordable, easy to use, versatile for various metals |

Ready to melt gold with precision and purity?

Whether you're a jeweler crafting intricate pieces or a commercial refiner requiring high-volume efficiency, choosing the right furnace is critical to your success. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable melting solutions.

Our experts can help you select the ideal furnace—from versatile muffle furnaces for versatile applications to high-speed induction furnaces for pure, efficient melts—ensuring you achieve consistent results every time.

Contact KINTEK today to discuss your gold melting requirements and discover the perfect equipment for your lab.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How does heat affect material strength? Understanding Thermal Degradation and Creep Failure

- What is the burning temperature of a furnace? From 200°C to 3000°C, It Depends on Your Needs

- How is the sintering temperature related to the melting temperature? A Guide to Solid-State Bonding

- What is the calibration frequency of a muffle furnace? A Risk-Based Guide to Ensure Precision

- What are the different types of heat transfer in a furnace? Mastering Conduction, Convection & Radiation