In short, heat fundamentally reduces material strength. As temperature increases, the atoms within a material gain energy and vibrate more intensely, weakening the bonds that hold them together. This makes the material less resistant to external forces, causing a measurable decrease in its overall strength and stiffness.

The core principle is that thermal energy works against a material's internal structure. By energizing atoms, heat makes it easier for them to move and slip past one another, reducing the force required to deform or break the material and introducing the risk of time-dependent failure under load.

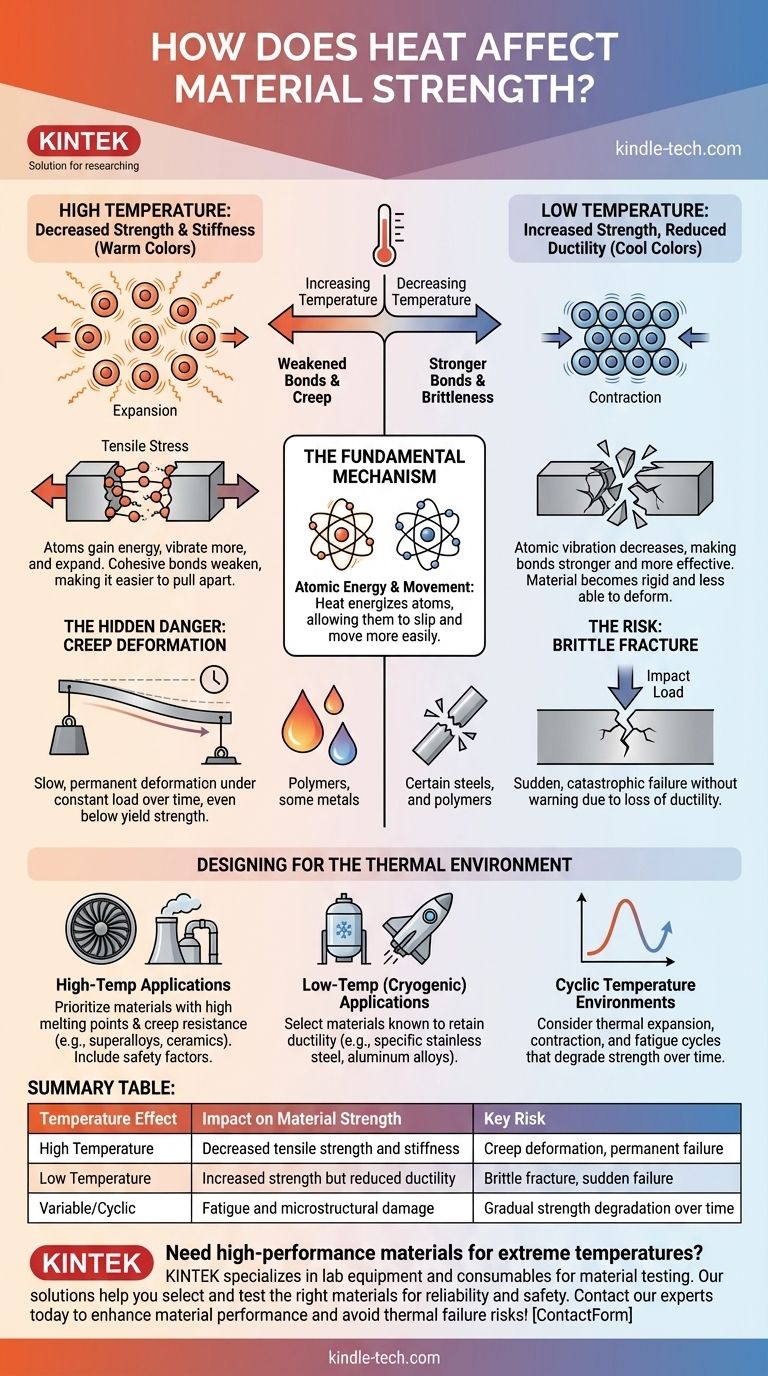

The Fundamental Mechanism: Atomic Energy and Movement

To understand why heat affects strength, we must look at the atomic level. A material's strength is derived from the powerful bonds between its atoms, which resist being pulled apart or forced into new arrangements.

The Impact on Tensile Strength

Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking. Heat provides atoms with the energy to vibrate, increasing the average distance between them. This expansion weakens the cohesive bonds, meaning less external force is needed to pull the atoms apart entirely.

The Reduction in Stiffness (Elastic Modulus)

Stiffness, or the elastic modulus, is a material's resistance to being deformed elastically (i.e., non-permanently). As atoms vibrate more energetically, they can be pushed and pulled from their equilibrium positions more easily. The result is a less rigid material that will bend or stretch more under the same applied load.

The Hidden Danger: Creep Deformation

One of the most critical effects of heat is a phenomenon that occurs over time. Even at stress levels well below a material's yield strength, heat can cause a slow, permanent deformation.

What is Creep?

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses, especially at elevated temperatures. Think of a heavy bookshelf that begins to sag over many years; heat dramatically accelerates this process.

Why Creep is a Critical Failure Mode

Creep is a primary concern in designing high-temperature components like jet engine turbine blades or power plant piping. Over time, this slow deformation can lead to a component changing shape, losing its structural integrity, and ultimately failing at a stress level it could have easily handled at a lower temperature.

Understanding the Trade-offs and Considerations

The relationship between temperature and strength is not one-sided. While high temperatures are often detrimental, low temperatures introduce their own set of challenges.

The Influence of Low Temperatures

As a material cools, atomic vibration decreases. This allows the interatomic bonds to become stronger and more effective, which generally increases the material's strength and stiffness. This is why some materials become exceptionally strong in cryogenic environments.

The Risk of Brittleness

The primary trade-off at low temperatures is the loss of ductility. Many common materials, particularly certain steels, can undergo a ductile-to-brittle transition. They become much stronger but lose their ability to deform, making them susceptible to shattering or fracturing suddenly under impact without any warning.

Not All Materials are Equal

The degree to which temperature affects strength varies enormously. Polymers are highly sensitive and can lose significant strength at even moderately elevated temperatures. Metals have a clear performance curve, while materials like ceramics and superalloys are specifically engineered to retain their strength at extreme temperatures.

Designing for the Thermal Environment

Ultimately, accounting for temperature is not an option; it is a fundamental requirement of sound engineering design. Your material selection must be directly informed by the operating thermal conditions.

- If your primary focus is high-temperature applications: Prioritize materials with high melting points and excellent creep resistance, such as nickel-based superalloys or engineering ceramics, and incorporate significant safety factors.

- If your primary focus is low-temperature (cryogenic) applications: Select materials known to retain their ductility and avoid brittle fracture, such as specific grades of stainless steel, aluminum alloys, or nickel alloys.

- If your primary focus is environments with temperature cycles: Consider the effects of thermal expansion, contraction, and material fatigue, as repeated cycles can degrade strength over time.

Always treat temperature not as a condition, but as a critical load case that directly governs material performance and reliability.

Summary Table:

| Temperature Effect | Impact on Material Strength | Key Risk |

|---|---|---|

| High Temperature | Decreased tensile strength and stiffness | Creep deformation, permanent failure |

| Low Temperature | Increased strength but reduced ductility | Brittle fracture, sudden failure |

| Variable/Cyclic | Fatigue and microstructural damage | Gradual strength degradation over time |

Need high-performance materials for extreme temperatures? KINTEK specializes in lab equipment and consumables for material testing and research. Whether you're designing for high-temperature applications requiring creep-resistant superalloys or cryogenic environments needing ductile materials, our solutions help you select and test the right materials for reliability and safety. Contact our experts today to enhance your material performance and avoid thermal failure risks!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the maximum temperature of muffle furnace? A Guide from 1100°C to 1800°C

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Lab's Needs

- How do you set up a muffle furnace? A Step-by-Step Guide for Safe and Accurate Operation

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage