Yes, heat treatment is one of the most powerful and widely used methods to fundamentally alter a metal's strength. This process allows engineers to precisely control the internal structure of a metal, tailoring its mechanical properties to meet specific performance requirements. While many treatments are designed to significantly increase strength and hardness, others are used to intentionally decrease them to improve ductility or machinability.

Heat treatment is not simply a switch for "more strength." It is a sophisticated tool for managing the critical trade-off between strength, hardness, and ductility by carefully manipulating the metal's microscopic crystal structure.

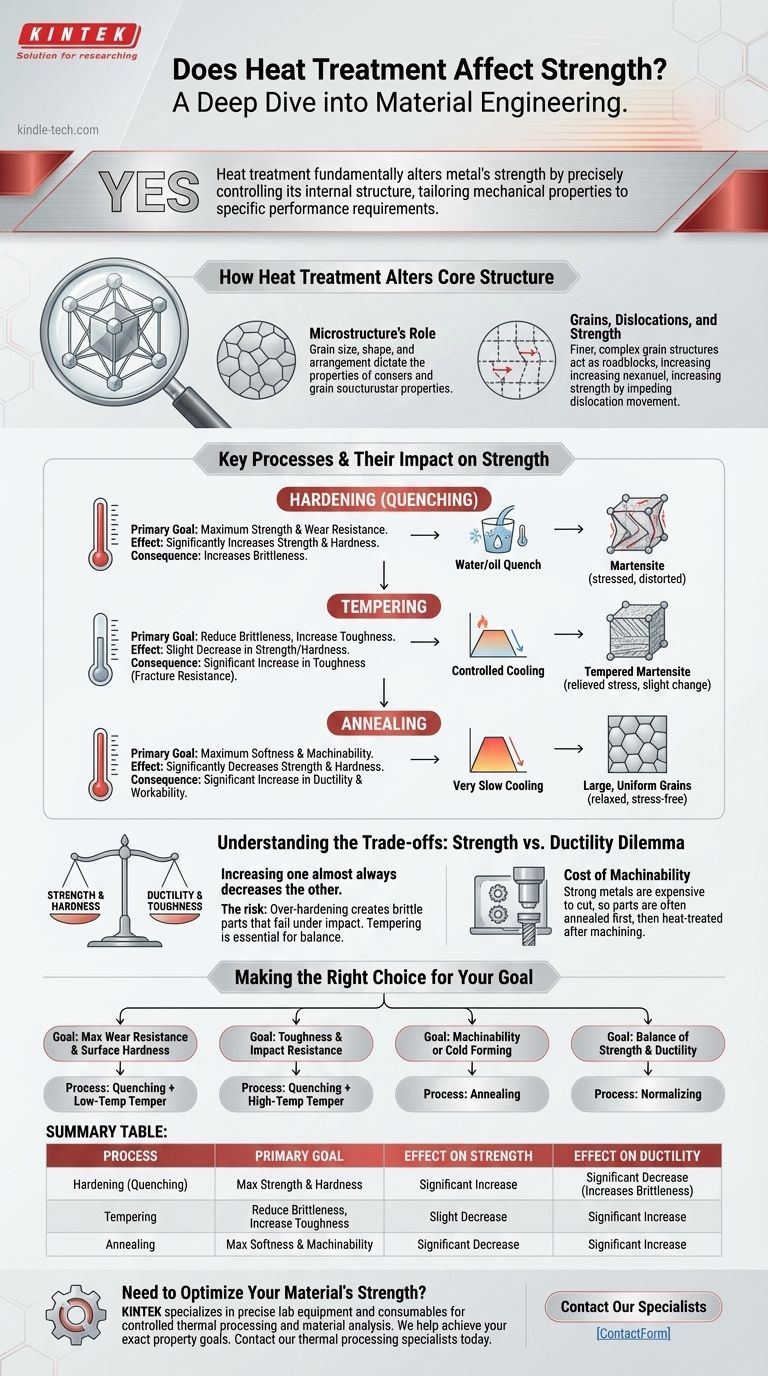

How Heat Treatment Alters a Metal's Core Structure

The Role of Microstructure

Metals are not uniform solids; they are composed of microscopic crystals called grains. The size, shape, and arrangement of these grains—known as the microstructure—directly dictate the metal's mechanical properties.

Heat treatment works by heating and cooling a metal under controlled conditions. This manipulates the grain structure, either locking in a strong, stress-filled arrangement or allowing the grains to reform into a softer, more relaxed state.

Grains, Dislocations, and Strength

Strength in a metal is largely a measure of its resistance to internal "slippage." When a metal is put under stress, defects in the crystal structure called dislocations begin to move. The easier it is for these dislocations to move, the weaker and more ductile the metal is.

Heat treatment processes like hardening create very fine, complex, and irregular grain structures. These structures act as roadblocks, impeding the movement of dislocations and thus making the metal significantly stronger and harder.

Key Processes and Their Impact on Strength

Hardening (Quenching)

Hardening is a process designed for maximum strength and wear resistance. It involves heating a metal (like steel) to a high temperature and then cooling it very rapidly, often by "quenching" it in water, oil, or air.

This rapid cooling traps the crystal structure in a highly stressed, distorted state called martensite. This structure is extremely effective at blocking dislocation movement, resulting in a very hard and strong, but also brittle, material.

Tempering

A part that has only been hardened is often too brittle for practical use. Tempering is a secondary heat treatment that follows quenching to reduce this brittleness.

The part is reheated to a lower temperature and held for a specific time. This process relieves some of the internal stresses and allows the microstructure to change slightly, sacrificing a small amount of strength and hardness to gain a significant amount of toughness (resistance to fracture).

Annealing

Annealing is the opposite of hardening. The goal is to make the metal as soft, ductile, and weak as possible, typically to make it easier to machine or form.

The process involves heating the metal and then cooling it very slowly. This slow cooling allows the grains to reform into a large, uniform, and stress-free structure. Dislocations can move easily through this structure, resulting in a soft and easily workable material.

Understanding the Trade-offs: The Strength vs. Ductility Dilemma

The Inherent Inverse Relationship

The most critical concept in heat treatment is the inverse relationship between strength and ductility. As you increase a metal's strength and hardness, you almost always decrease its ductility and toughness.

A highly strengthened material will resist bending and scratching, but it may shatter under a sudden impact. A softer, more ductile material will bend and deform before it breaks.

The Risk of Over-Hardening

Choosing a treatment that maximizes strength without considering toughness is a common pitfall. A gear or shaft that is excessively hard can become brittle and fail catastrophically under shock loading, causing far more damage than a part that simply wears out over time.

Tempering is the essential step that balances these properties, creating a component that is both strong enough for its task and tough enough to survive real-world conditions.

The Cost of Machinability

A very strong, hard metal is difficult, slow, and expensive to machine. The tools required to cut it wear out quickly.

For this reason, a part is often purchased in a soft, annealed state. It is machined to its final shape and dimensions, and only then is it heat-treated (hardened and tempered) to achieve the final desired strength.

Making the Right Choice for Your Goal

The correct heat treatment is entirely dependent on the final application of the component.

- If your primary focus is maximum wear resistance and surface hardness: Your path is quenching followed by a low-temperature temper to maintain as much hardness as possible.

- If your primary focus is toughness and impact resistance: You will need to quench and then temper at a higher temperature, sacrificing some hardness to gain crucial ductility.

- If your primary focus is machinability or cold forming: Your ideal process is annealing to intentionally reduce strength and create the softest possible material.

- If your primary focus is a balance of strength and ductility without extreme hardness: Normalizing is often used to refine the grain structure and provide better mechanical properties than annealing without the stresses of quenching.

Ultimately, viewing heat treatment as a precise instrument for engineering material properties is the key to creating successful, reliable components.

Summary Table:

| Heat Treatment Process | Primary Goal | Effect on Strength | Effect on Ductility |

|---|---|---|---|

| Hardening (Quenching) | Maximum Strength & Hardness | Significantly Increases | Significantly Decreases (Increases Brittleness) |

| Tempering | Reduce Brittleness, Increase Toughness | Slightly Decreases | Significantly Increases |

| Annealing | Maximum Softness & Machinability | Significantly Decreases | Significantly Increases |

Need to Optimize Your Material's Strength?

Choosing the right heat treatment is critical for your component's performance, durability, and cost-effectiveness. The experts at KINTEK specialize in providing the precise lab equipment and consumables needed for controlled thermal processing and material analysis.

We help laboratories and manufacturers achieve their exact property goals—whether it's maximum hardness, superior toughness, or improved machinability.

Let's discuss your application requirements. Contact our thermal processing specialists today to find the ideal solution for your needs.

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the function of the heat treatment process? Tailor Material Properties for Your Application

- What are the advantages of metal sintering? Achieve Cost-Effective, Complex Metal Parts

- What is plasma torch gasification as a method to dispose hazardous waste? Convert Hazardous Waste into Clean Energy & Inert Slag

- What is the source of electron beam welding? The High-Voltage Power Supply Explained

- What is the primary function of a vacuum resistance furnace in the recovery of hazardous magnesium waste?

- Why are biopalladium samples processed in a vacuum drying oven? Ensuring Sample Integrity for SEM Analysis

- What are powder sintering methods? A Guide to Metal & Ceramic Part Manufacturing

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals