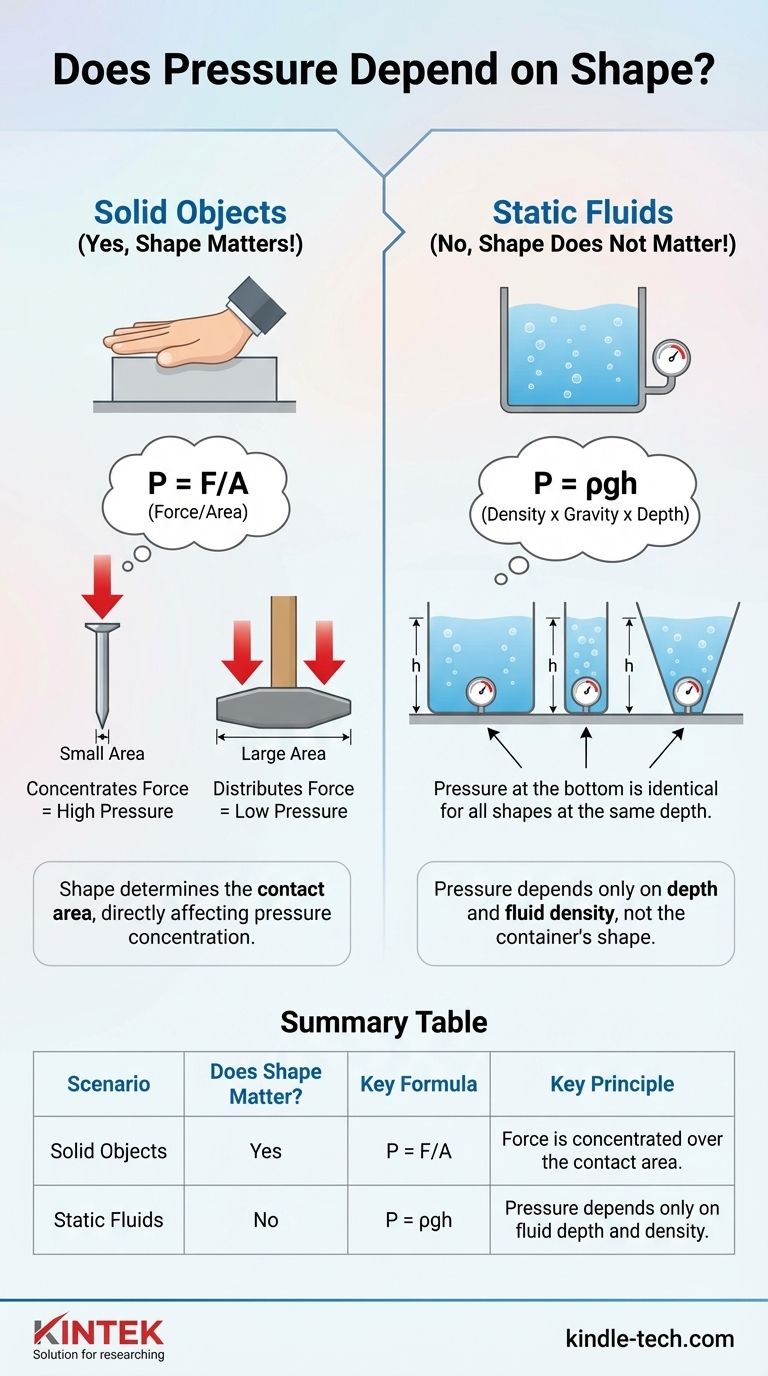

In short, the answer depends entirely on the context. For a solid object exerting force, the shape of its contact point is the most critical factor determining pressure. Conversely, for a fluid at a given depth, the pressure it exerts is completely independent of the container's shape.

Pressure is fundamentally defined as force distributed over an area (P = F/A). The common confusion about the role of shape arises because the factors determining that force and area change dramatically between solid objects and fluids.

The Role of Shape in Solid Objects

When a solid object pushes against a surface, its shape dictates the size of the contact area. This relationship is the key to understanding how pressure is generated and controlled in mechanical systems.

The Fundamental Formula: P = F/A

The definition of pressure is Force (F) per unit Area (A). This simple formula governs every interaction between solid objects.

It tells us that for a given amount of force, a smaller area will result in a much higher pressure.

How "Shape" Translates to Area

In the context of solids, when we discuss "shape," we are almost always referring to the contact area.

A sharp object, like a knife's edge or a nail's tip, is specifically designed to have an infinitesimally small contact area. A blunt object, like a hammer's face, has a large one.

The Principle of Force Concentration

A small area concentrates the applied force. This is the central principle behind countless tools.

Even a modest force from your hand, when concentrated onto the tiny tip of a needle, creates immense pressure—enough to easily pierce skin. The force is the same, but the shape changes the pressure.

Why Shape is Irrelevant for Fluid Pressure

In a static fluid (one that is not flowing), the rules change completely. The pressure at any point is determined not by the container, but by the weight of the fluid column sitting above that point.

The Concept of Hydrostatic Pressure

The pressure you feel deep underwater comes from the total weight of the water column directly above you, stretching all the way to the surface.

This is called hydrostatic pressure. It pushes equally in all directions at a given depth.

The Formula: P = ρgh

The formula for hydrostatic pressure is P = ρgh, where:

- ρ (rho) is the density of the fluid.

- g is the acceleration due to gravity.

- h is the height, or depth, of the fluid.

Notice that the volume, width, or overall shape of the container is completely absent from this equation. The only spatial dimension that matters is depth.

The Hydrostatic Paradox

This leads to a famously counterintuitive result. Imagine three vessels: one wide, one narrow, and one with sloping sides. If all have the same base area and are filled with water to the exact same height, the force on the bottom of each vessel is identical.

This is true even though the total weight of water in the wide vessel is far greater than in the narrow one. The pressure at the bottom only depends on the height (h), and that pressure acts on the same base area, resulting in the same force.

Understanding the Pitfalls

Applying the wrong principle to a given scenario is the most common source of error when analyzing pressure. Understanding the boundaries of each concept is critical.

The Most Common Mistake

The most frequent error is to intuitively apply the rules of solids to fluids. We might assume a wider lake exerts more pressure at the bottom than a narrow well of the same depth. This is incorrect.

The pressure at the bottom of a 10-meter-deep well is identical to the pressure 10 meters below the surface of the ocean.

Ideal vs. Real-World Fluids

The hydrostatic formula (P = ρgh) assumes an incompressible fluid with uniform density. For liquids like water under normal conditions, this is a highly accurate model.

For highly compressible fluids like gases, or in situations with extreme temperature and density variations, more complex calculations are required.

Static vs. Dynamic Pressure

This entire discussion has been about static pressure in non-moving systems.

When a fluid is in motion, we must also consider dynamic pressure, which is related to the fluid's velocity. This is governed by different principles, such as Bernoulli's principle.

How to Apply This to Your Problem

To determine if shape matters, first identify the nature of your system. Your goal will dictate which principle to apply.

- If your primary focus is mechanical design: You must assume that shape is a critical factor. Manipulating the contact area of parts is a fundamental tool for managing stress, friction, and wear.

- If your primary focus is hydraulics or civil engineering: You must work from the principle that pressure depends on fluid depth and density, not the shape of the pipe, reservoir, or dam.

- If your primary focus is general physics: Remember the core distinction—pressure in solids is about the application area of a specific force, while pressure in fluids is about the weight of the column above a specific point.

By correctly identifying whether you are dealing with a solid force or a fluid column, you can confidently determine when shape is the most important factor and when it is irrelevant.

Summary Table:

| Scenario | Does Shape Matter? | Key Formula | Key Principle |

|---|---|---|---|

| Solid Objects | Yes | P = F/A | Force is concentrated over the contact area. |

| Static Fluids | No | P = ρgh | Pressure depends only on fluid depth and density. |

Need precise control over pressure in your lab processes?

Whether you're designing equipment that handles solid materials or working with fluid systems, understanding pressure is fundamental to achieving accurate and repeatable results. At KINTEK, we specialize in providing high-quality lab equipment and consumables that are engineered for precision and reliability.

Let our experts help you select the right tools for your specific application. Contact us today to discuss your laboratory needs and discover how KINTEK can support your research and development goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What are the factors that affect melting and boiling point? Unlock the Science of Phase Transitions

- Why should hesperidin samples be stored in amber glass and ULT freezers? Preserve Bioactivity and Sample Integrity

- What is the boiling point of pyrolysis oil? Understanding Its Complex Boiling Range

- What is advanced pyrolysis? From Waste to High-Value Circular Feedstock

- What does a hot air oven do in a laboratory? Essential Sterilization & Drying for Your Lab

- What is the maximum service temperature for brazed joints? Unlock the Key to Joint Reliability and Performance

- What are the limitations of fluidized bed reactor? Key Challenges in Design and Operation

- What are the benefits of biomass pellets? A Sustainable, Cost-Effective Fuel Alternative