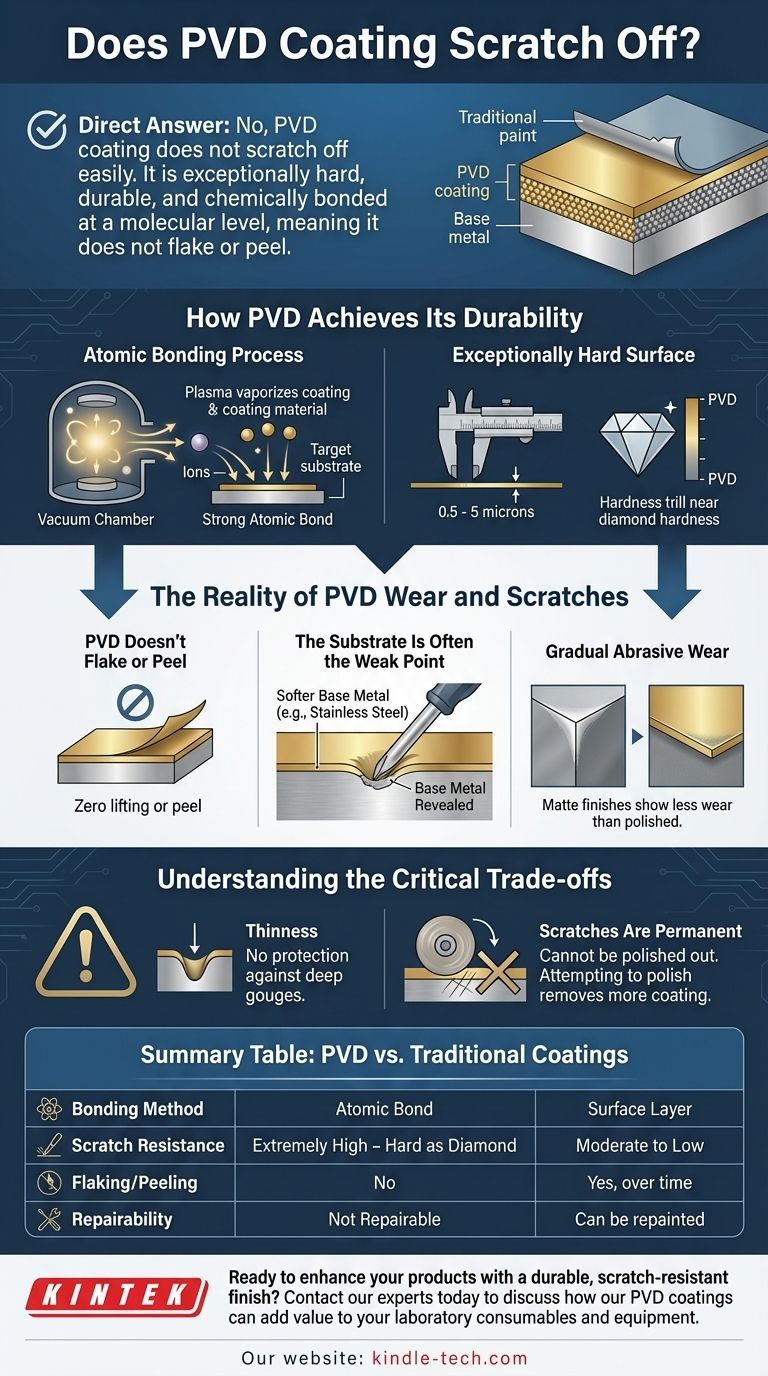

To be direct, PVD coating does not scratch off easily. While any surface can be damaged with enough force, PVD (Physical Vapor Deposition) coatings are exceptionally hard and durable. They are bonded to the base metal at a molecular level, meaning they don't flake or peel like paint. A scratch typically signifies that the underlying metal has been gouged, taking the thin coating with it.

The core issue isn't whether PVD coatings scratch, but understanding that they are an incredibly thin, super-hard layer bonded to a softer base metal. True damage occurs when an impact is hard enough to deform the base metal itself, revealing it from underneath the otherwise intact PVD layer.

How PVD Achieves Its Durability

PVD is not a wet application like painting or electroplating. It's a high-tech vacuum deposition process that creates a superior bond and a harder surface.

The Process of Atomic Bonding

The PVD process takes place in a vacuum chamber where a solid coating material (like titanium or chromium) is vaporized into plasma. These microscopic particles are then deposited onto the target object.

This process bombards the substrate with ions, embedding the coating material into the surface of the part itself. The result is a strong, atomic bond rather than just a simple layer sitting on top.

Creating an Exceptionally Hard Surface

The resulting coating is incredibly thin, often just 0.5 to 5 microns, but it is extremely hard—in some cases approaching the hardness of diamond.

This inherent hardness is what provides its remarkable resistance to scuffs and minor scratches from everyday contact. It also offers excellent protection against corrosion and oxidation.

The Reality of PVD Wear and Scratches

Because PVD is so different from traditional coatings, the way it shows wear is also different. It is highly resistant to damage, but not indestructible.

PVD Doesn't Flake or Peel

Unlike paint or other plating methods, properly applied PVD coatings will not fall off on their own. The molecular bond ensures the coating remains adhered to the substrate through significant stress.

The Substrate Is Often the Weak Point

Most PVD coatings are applied to materials like stainless steel. While the PVD layer is incredibly hard, the stainless steel beneath it is much softer.

A sharp impact or a deep, forceful drag across an abrasive surface can gouge the base metal. When this happens, the metal is displaced, and the thin PVD coating is removed along with it, exposing the silver-colored steel underneath.

Gradual Abrasive Wear

While resistant to sharp scratches, the coating can wear down over time from continuous friction, especially on sharp edges and corners.

Matte finishes tend to show this gradual wear less obviously than polished or metallic finishes, as the change in texture is less pronounced.

Understanding the Critical Trade-offs

PVD offers best-in-class durability for a colored finish, but it comes with one significant limitation that you must understand before you buy.

The Problem of Thinness

The coating's extreme thinness is both a strength (it doesn't alter a part's dimensions) and a weakness. Because it is only a few microns thick, it offers no practical protection against dents and deep gouges.

Scratches Are Permanent

This is the most critical takeaway. You cannot polish a scratch out of a PVD coating.

Any attempt to use an abrasive polish to remove a scratch will simply remove the PVD coating in that area, making the blemish larger and more obvious. Once a PVD finish is scratched to reveal the base metal, the damage is permanent.

Making the Right Choice for Your Goal

Understanding how PVD performs allows you to select it for the right application.

- If your primary focus is aesthetic perfection: Recognize that while PVD is the toughest colored finish available, a severe impact will create a permanent mark that cannot be repaired.

- If your primary focus is functional durability: For tools, components, or everyday items, PVD provides exceptional resistance to the scuffs, wear, and corrosion that would quickly ruin lesser finishes.

- If your primary focus is everyday use: PVD is an excellent choice for watches, jewelry, and fixtures, as it will easily withstand daily contact and look new for far longer than other coatings.

Ultimately, PVD coating offers the highest level of scratch resistance you can get from a surface finish, but it is not immune to the laws of physics.

Summary Table:

| Characteristic | PVD Coating | Traditional Coatings (e.g., Paint) |

|---|---|---|

| Bonding Method | Atomic/Molecular Bond | Surface Layer |

| Scratch Resistance | Extremely High (Hard as Diamond) | Moderate to Low |

| Flaking/Peeling | No | Yes, over time |

| Wear Appearance | Gouge reveals base metal | Flaking and color loss |

| Repairability | Not Repairable (Permanent if scratched) | Can be repainted/refinished |

Ready to enhance your products with a durable, scratch-resistant finish?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment and precision components. Our coatings provide exceptional hardness and longevity, ensuring your products withstand daily wear and corrosion.

Contact our experts today to discuss how our PVD coatings can add value and durability to your laboratory consumables and equipment.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings