At its core, the CVD process is a form of additive manufacturing for diamonds. It uses a low-pressure, high-temperature chamber to break down carbon-rich gas, allowing carbon atoms to deposit onto a diamond "seed" and grow a new, larger diamond layer by layer. This method doesn't mimic the brute force of nature; it builds a diamond with atomic precision.

Unlike processes that replicate the Earth's immense pressure, Chemical Vapor Deposition (CVD) is a sophisticated technique that "grows" a diamond from a gas. It offers exceptional control over the diamond's purity and properties by constructing it one atomic layer at a time.

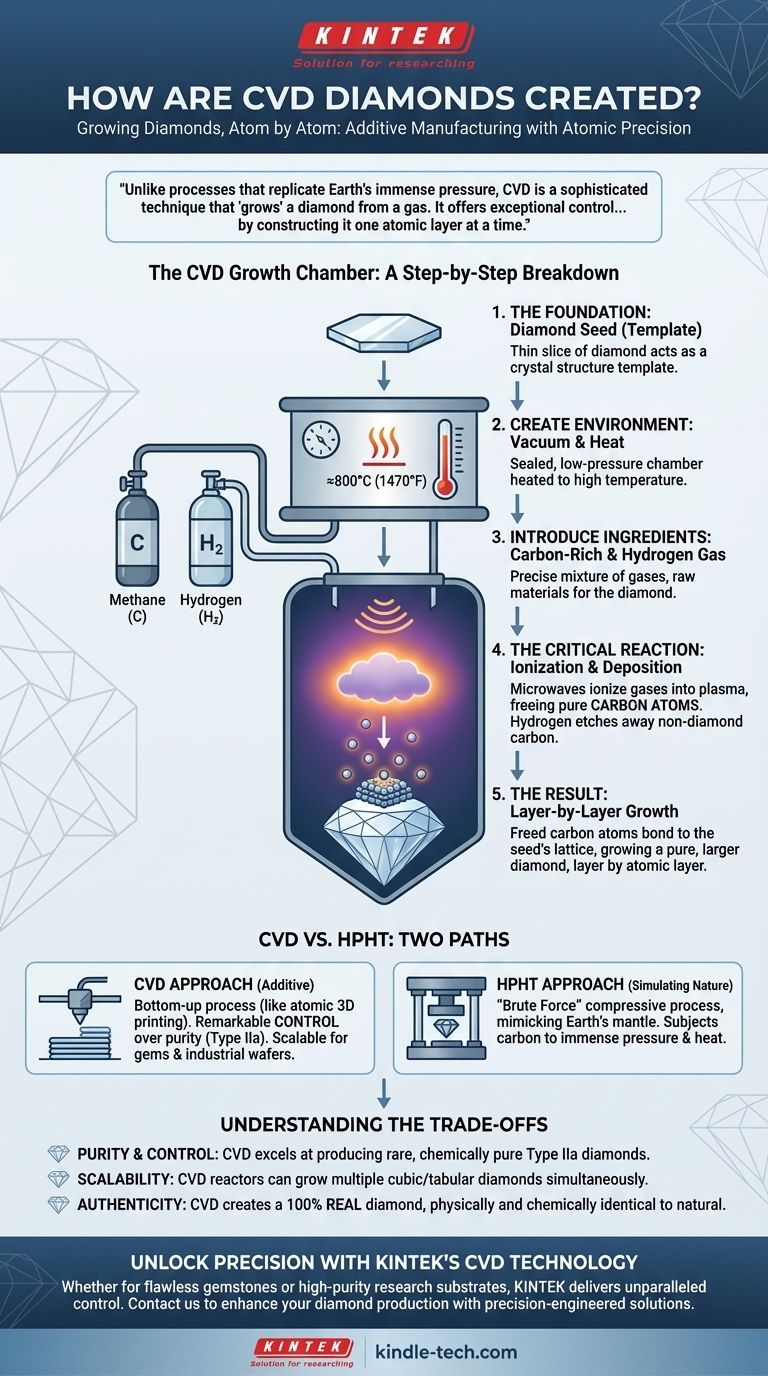

The CVD Growth Chamber: A Step-by-Step Breakdown

The CVD method transforms gas into one of the hardest materials on Earth. The process is highly controlled and takes place inside a specialized vacuum chamber.

The Foundation: The Diamond Seed

The process begins with a diamond seed. This is a very thin, flat slice of a previously grown diamond (either natural or lab-created).

This seed acts as the template, providing the crystal structure for the new carbon atoms to bond to.

Creating the Environment: Vacuum and Heat

The diamond seed is placed inside a sealed, low-pressure chamber. All other gases are pumped out to create a vacuum.

The chamber is then heated to an extremely high temperature, typically around 800°C (approx. 1470°F).

Introducing the Ingredients: Carbon and Hydrogen Gas

A precise mixture of carbon-rich gas (usually methane) and pure hydrogen is introduced into the chamber. These gases are the raw materials for the new diamond.

The Critical Reaction: Ionization and Deposition

Energy, often in the form of microwaves, is used to ionize the gases, stripping the molecules of their electrons and turning them into a plasma cloud.

This reaction breaks the molecular bonds, freeing pure carbon atoms. The hydrogen gas plays a crucial role by selectively etching away any non-diamond carbon (like graphite), ensuring only pure diamond crystals form.

The Result: Layer-by-Layer Growth

The freed carbon atoms are drawn down to the cooler diamond seed at the bottom of the chamber.

They bond with the seed's crystal lattice, perfectly replicating its structure. This happens layer by atomic layer, slowly growing the seed into a larger, chemically pure diamond.

CVD vs. HPHT: Two Paths to the Same Material

While both CVD and HPHT produce real diamonds, their founding principles are fundamentally different. Understanding this distinction is key to appreciating their characteristics.

The CVD Approach: Additive Manufacturing

CVD is a "bottom-up" process. Think of it like 3D printing on an atomic scale. Because it's an additive process, it allows for remarkable control over the final product's purity.

This method's flexibility allows for growing diamonds over large areas or on various substrates, making it ideal for both gem-quality stones and advanced industrial applications.

The HPHT Approach: Simulating Nature

The High-Pressure/High-Temperature (HPHT) method mimics the conditions deep within the Earth's mantle. It takes a carbon source and subjects it to immense pressure and heat, forcing it to crystallize into a diamond.

This "brute force" method is fundamentally a compressive process, more akin to how natural diamonds are formed.

Understanding the Trade-offs

The choice of growth method has direct implications for the final diamond's properties and how it's used.

Purity and Control

The CVD process excels at producing Type IIa diamonds, a classification for the most chemically pure diamonds. These are very rare in nature but are the standard for CVD. This is because the controlled, low-pressure environment prevents common impurities like nitrogen from entering the crystal lattice.

Scalability and Shape

CVD reactors can grow multiple diamonds simultaneously. The diamonds typically grow in a cubic or tabular (flat) shape, which is then cut into the desired gemstone. This scalability makes the process highly efficient.

Potential for Post-Growth Treatments

While CVD allows for high control, some resulting diamonds may require post-growth treatment to enhance their color. This is a standard practice and is always disclosed in a reputable gemological report.

Making the Right Choice for Your Goal

Understanding how CVD diamonds are made allows you to assess their value based on your specific needs.

- If your primary focus is obtaining a chemically pure and high-clarity diamond: The CVD method is an excellent choice, as the process inherently limits the formation of inclusions and nitrogen impurities.

- If your primary focus is on a specific technological application: CVD's ability to grow diamond wafers on different substrates makes it the superior method for electronics, optics, and other industrial uses.

- If your primary concern is authenticity: Rest assured that CVD creates a 100% real diamond, physically and chemically identical to a natural one. Gemological labs can identify its origin as lab-grown but confirm its identity as a true diamond.

By understanding the science, you can recognize CVD diamonds not as mere copies, but as marvels of material science engineered with incredible precision.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Seed Preparation | Place a thin diamond slice in a vacuum chamber | Provides a crystal template for new carbon atoms to bond |

| 2. Environment Setup | Heat chamber to ~800°C and introduce methane/hydrogen gas | Creates ideal conditions for carbon deposition |

| 3. Ionization | Use microwaves to ionize gases into plasma | Breaks molecular bonds to free pure carbon atoms |

| 4. Deposition & Growth | Carbon atoms bond to seed in atomic layers | Slowly builds a larger, pure diamond crystal |

| 5. Result | A real, lab-grown diamond is formed | Chemically identical to natural diamonds, with high purity |

Unlock Precision with KINTEK's CVD-Grown Diamonds

Whether you're a jeweler seeking flawless gemstones or a researcher needing high-purity diamond substrates, KINTEK's advanced CVD technology delivers unparalleled control and quality. Our lab equipment and consumables are designed to support your specific needs, from high-clarity gems to cutting-edge industrial applications.

Contact us today to learn how KINTEK can enhance your diamond production or research with reliable, precision-engineered solutions.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the challenges of carbon nanotubes? Overcoming Production and Integration Hurdles

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- Are all lab grown diamonds CVD? Understanding the Two Main Methods