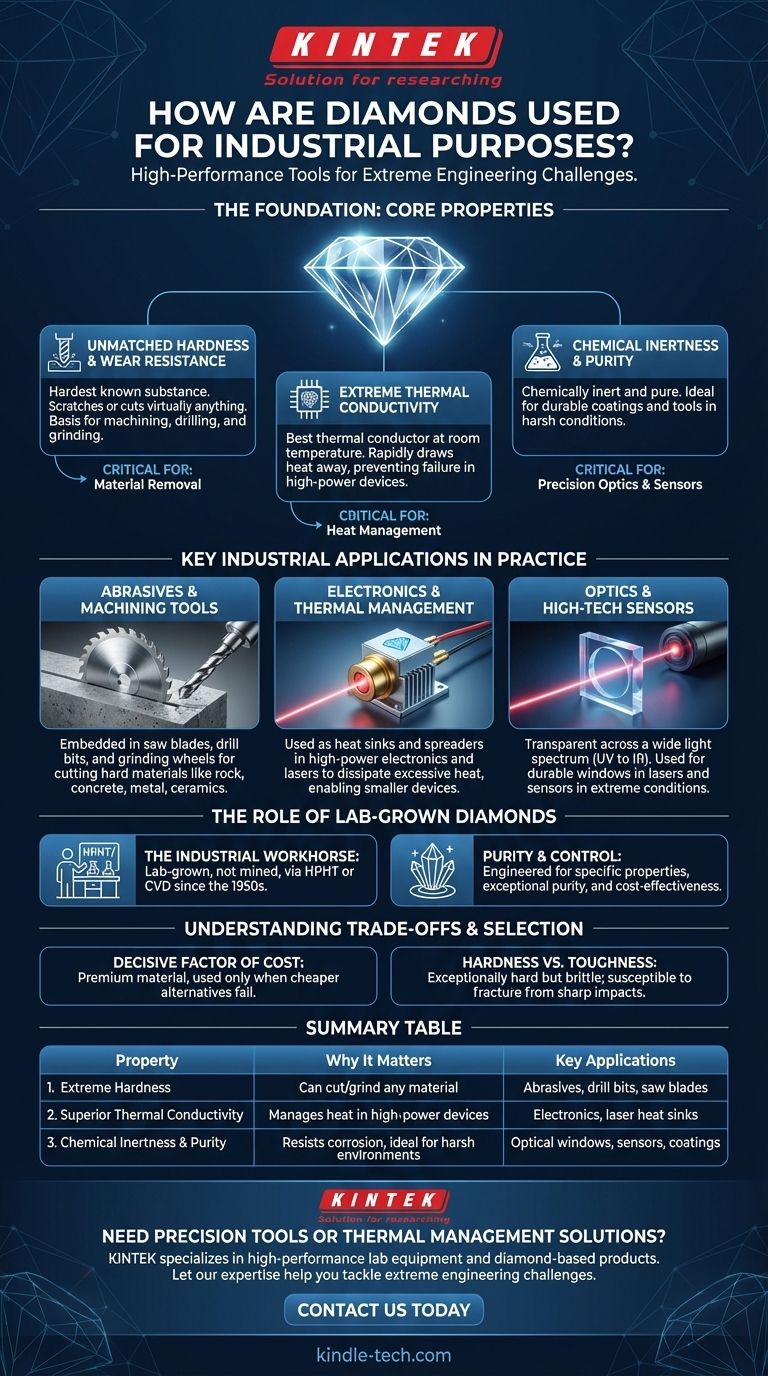

In industry, diamonds are not gems but high-performance tools. They are used for tasks that require extreme material properties, primarily in cutting and grinding hard materials, managing heat in advanced electronics, and in high-precision optical and medical applications. This utility stems from a unique combination of physical characteristics that no other material can match.

A diamond's industrial value has nothing to do with its beauty. It is prized by engineers for its unparalleled hardness and its ability to conduct heat more efficiently than any other bulk material, making it a critical component for solving extreme engineering challenges.

The Foundation: Why Diamond is an Unrivaled Industrial Material

To understand its applications, you must first understand its core properties. A diamond is a material of extremes, which makes it an ideal solution for problems where conventional materials fail.

Unmatched Hardness and Wear Resistance

A diamond is the hardest known natural substance. This means it can scratch or cut virtually any other material without being damaged itself.

This extreme hardness and wear resistance are the most famous of its industrial properties, forming the basis for its widespread use in machining and drilling.

Extreme Thermal Conductivity

Less known, but equally critical, is that diamond is the best thermal conductor of any bulk material at room temperature. It acts as a superhighway for heat.

This property allows it to rapidly draw heat away from sensitive components, preventing them from overheating and failing under high-power operation.

Chemical Inertness and Purity

Diamonds are chemically inert, meaning they do not easily react with other substances. This makes them ideal for durable coatings and tools that operate in harsh environments.

For specialized applications in electronics and optics, the purity and uniformity of lab-grown diamonds allow for performance that is predictable and consistent.

Key Industrial Applications in Practice

These fundamental properties translate directly into specific, high-value applications across several major industries.

Abrasives and Machining Tools

The most common industrial use of diamond is as an abrasive. Tiny diamond particles are embedded into saw blades, drill bits, and grinding wheels.

These tools are essential for shaping, cutting, and drilling very hard or abrasive materials like rock, concrete, metal, and ceramics with high precision.

Electronics and Thermal Management

In high-power electronics and lasers, excessive heat is a primary cause of failure. Diamonds are used as heat sinks or spreaders.

They are placed in direct contact with a hot microchip or laser diode to pull heat away efficiently, enabling smaller, more powerful electronic devices.

Optics and High-Tech Sensors

Because a pure diamond crystal has a highly uniform structure, it is transparent to a wide range of light, from ultraviolet to infrared.

This makes it valuable for creating durable windows for lasers, sensors in high-energy physics experiments, and specialized optical components that must withstand extreme conditions.

The Critical Role of Lab-Grown Diamonds

It is a common misconception that industrial applications rely on flawed, mined gems. In reality, the vast majority of industrial diamonds are specifically grown in a lab.

The Industrial Workhorse

Lab-grown diamonds, produced via processes like HPHT (High-Pressure, High-Temperature) or CVD (Chemical Vapor Deposition), have been the standard for industrial use since the 1950s.

Purity, Uniformity, and Cost

Growing diamonds in a controlled environment allows for the creation of crystals with specific properties, exceptional purity, and fewer defects than natural stones.

This process is also significantly less expensive than mining, making the use of diamond economically viable for a wide range of industrial applications.

Identical Properties, Superior Control

Lab-grown diamonds are physically and chemically identical to natural diamonds. The key difference is the ability to engineer them for a specific task, optimizing properties like thermal conductivity or electrical resistance.

Understanding the Trade-offs

While its properties are unmatched, diamond is not a universal solution. Its use is dictated by a balance of performance and practicality.

The Decisive Factor of Cost

Even lab-grown diamonds are a premium material. They are typically only used when no other cheaper material, like silicon carbide or tungsten carbide, can withstand the operational demands.

Hardness vs. Toughness

While diamond is exceptionally hard (resistant to scratching), it can be brittle. A sharp, powerful impact can cause it to fracture. Engineers must design diamond tools and components to account for this.

How Diamond is Selected for a Task

The decision to use diamond is always purpose-driven. It is chosen when a specific, extreme property is the only way to achieve the desired outcome.

- If your primary focus is material removal (cutting, drilling, grinding): Diamond is chosen for its extreme hardness and superior wear resistance.

- If your primary focus is thermal management in electronics: Diamond is chosen for its unparalleled thermal conductivity to protect critical, high-power components.

- If your primary focus is precision optics or sensors: Diamond is chosen for its purity, structural uniformity, and transparency across a wide electromagnetic spectrum.

Ultimately, industrial diamond is a testament to how a material's true value lies in its ability to solve problems that nothing else can.

Summary Table:

| Property | Why It Matters | Key Applications |

|---|---|---|

| Extreme Hardness | Can cut/grind any material | Abrasives, drill bits, saw blades |

| Superior Thermal Conductivity | Manages heat in high-power devices | Electronics, laser heat sinks |

| Chemical Inertness & Purity | Resists corrosion, ideal for harsh environments | Optical windows, sensors, coatings |

Need precision tools or thermal management solutions? KINTEK specializes in high-performance lab equipment and consumables, including diamond-based products for cutting, grinding, and thermal applications. Let our expertise help you tackle extreme engineering challenges—contact us today to discuss your specific needs!

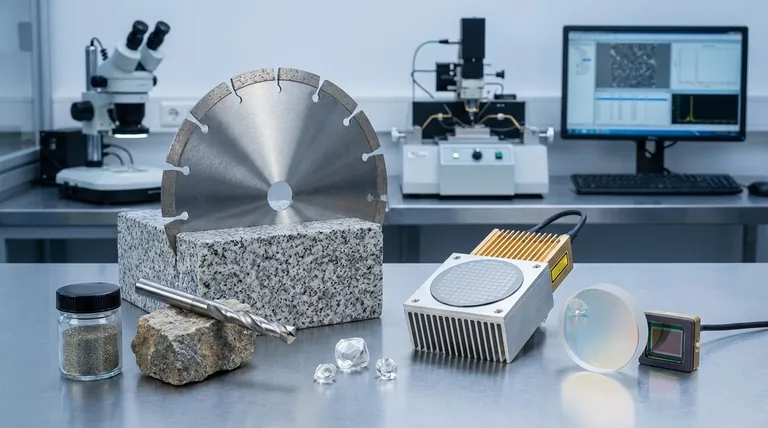

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What are autoclaves used in the chemical industry? High-Pressure Reactors for Synthesis & Curing

- What reactor is used for high pressure reactions? Select the Right Autoclave for Your Lab

- What are the advantages of a chemical reactor? Unlock Precision, Efficiency, and Safety in Your Process

- How high pressure is created in a lab? Master Safe and Precise Pressure Generation

- What is the temperature range of a stainless steel reactor? Understand the Real-World Limits for Your Process