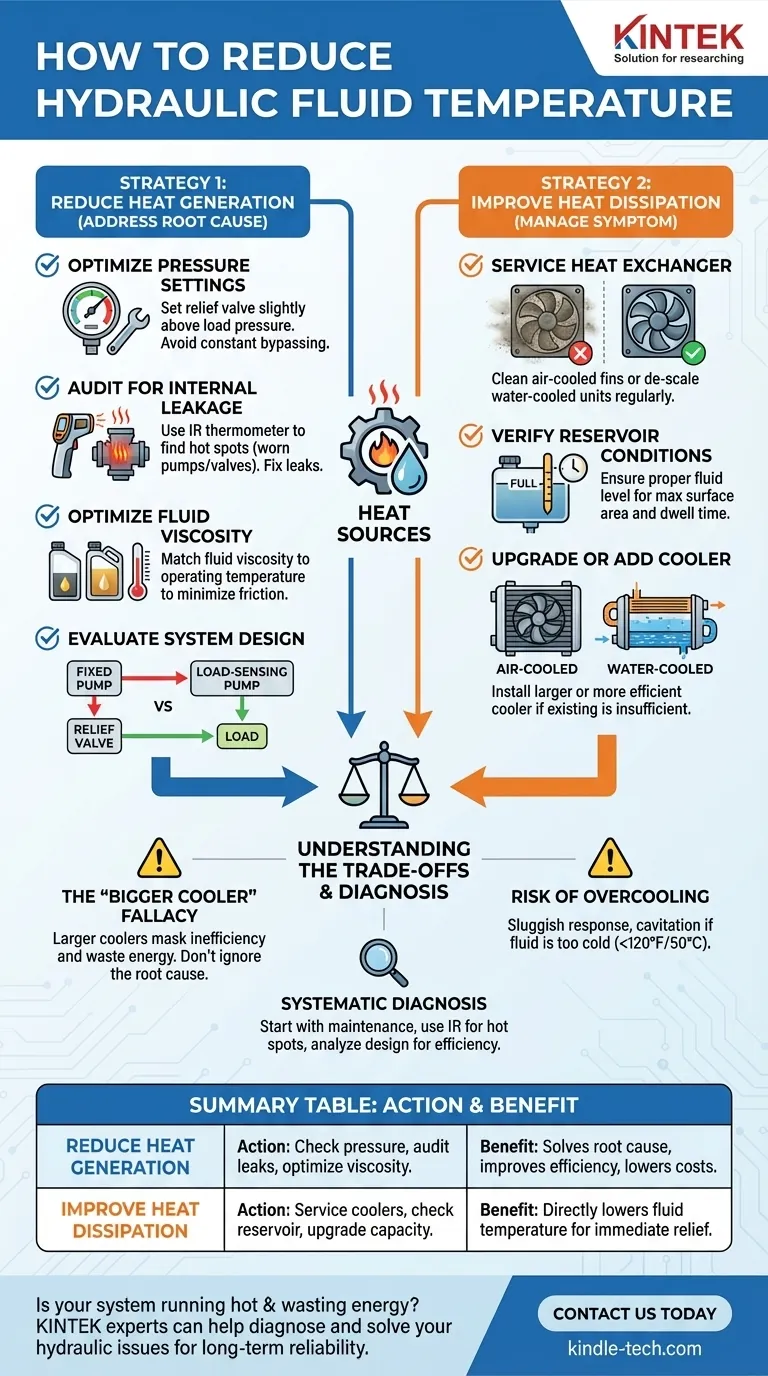

Reducing hydraulic fluid temperature is achieved by following two fundamental principles: decreasing the amount of heat the system generates or increasing its capacity to dissipate that heat. The most effective solutions address the root cause of heat generation, which is almost always system inefficiency, before resorting to simply adding more cooling capacity.

Overheating in a hydraulic system is a symptom, not the disease. The core issue is wasted energy. The most reliable and cost-effective solution is to first diagnose and correct the sources of inefficiency creating the excess heat, rather than just treating the symptom with a larger cooler.

Understanding the Source of Heat

All heat in a hydraulic system is a byproduct of wasted energy. Every component that adds heat is a point of inefficiency. Understanding these sources is the first step in diagnosing an overheating problem.

The Principle of Inefficiency

A perfectly efficient hydraulic system would convert 100% of input power into useful work, generating no heat. This is impossible in practice. Heat is generated whenever fluid flow is met with resistance that does not produce work.

Flow Across a Pressure Drop

This is the single largest source of heat in most hydraulic systems. When hydraulic fluid moves from an area of high pressure to an area of low pressure without performing work (like lifting a cylinder), the energy is converted directly into heat.

Common culprits include relief valves that are constantly bypassing flow, throttling valves used to control speed, and pressure-reducing valves.

Internal Component Leakage

As components like pumps, motors, and cylinders wear, internal seals degrade. This allows high-pressure fluid to leak past the seals directly to a low-pressure path within the component.

This internal leakage performs no work and converts all its pressure energy into heat. A worn pump or cylinder can become a significant, hidden heat generator.

Fluid and Mechanical Friction

Heat is also generated by the fluid's own internal friction as it moves through hoses, tubes, and fittings. Using a fluid with a viscosity that is too high for the operating conditions will increase this friction and generate more heat.

Mechanical friction between moving parts in pumps and motors also contributes, though it is usually a smaller factor than pressure drop inefficiencies.

Strategy 1: Reduce Heat Generation

Before trying to improve cooling, the first priority should always be to minimize the amount of heat being created. This is the most efficient and sustainable approach.

Check System Pressure Settings

Ensure the system's relief valve is set slightly above the maximum load pressure, not significantly higher. If a relief valve is constantly opening and dumping fluid back to the tank, it's a massive source of heat.

Audit for Internal Leakage

Use an infrared (IR) thermometer to scan components under load. A pump, valve, or actuator that is significantly hotter than the surrounding lines is a strong indicator of excessive internal leakage. This points to a worn component that needs service or replacement.

Optimize Fluid Viscosity

Verify that you are using the hydraulic fluid viscosity recommended by the equipment manufacturer for your ambient operating temperature. Fluid that is too thick increases fluid friction, while fluid that is too thin increases internal leakage—both create heat.

Evaluate System Design for Inefficiencies

For systems with constant overheating issues, evaluate the core design. A system using a fixed-displacement pump that sends excess flow over a relief valve is inherently inefficient.

Upgrading to a pressure-compensated or load-sensing pump can dramatically reduce heat, as these designs only produce the flow and pressure required by the load.

Strategy 2: Improve Heat Dissipation

If the system is designed efficiently and is in good repair but still runs hot, the next step is to improve its ability to get rid of the heat it generates.

Service the Existing Heat Exchanger

The most common cause of reduced cooling is a dirty or clogged heat exchanger (cooler). For air-cooled exchangers, ensure the cooling fins are clean of dust, grease, and debris. For water-cooled exchangers, check for internal scaling or sediment that restricts flow.

Verify Proper Reservoir Conditions

The hydraulic reservoir itself is a passive heat exchanger. Ensure the fluid level is at the proper "full" mark. A low fluid level reduces the surface area available for cooling and decreases the time the fluid has to cool down in the tank (dwell time).

Upgrade or Add a Cooler

If the existing cooler is clean and functional but still insufficient, an upgrade is necessary.

- Air-cooled (radiator-style): Best for mobile equipment and most industrial applications where a water source is unavailable.

- Water-cooled (shell-and-tube): More compact and efficient, but requires a reliable source of cool water. They are excellent for stationary industrial equipment.

Understanding the Trade-offs

Solving heat issues requires a balanced approach. A quick fix may have unintended consequences.

The "Bigger Cooler" Fallacy

Simply installing a larger heat exchanger can mask a serious underlying problem, like a failing pump. The system may run cooler, but the inefficiency is still present, wasting energy and increasing fuel or electricity costs. The failing component will eventually break down completely.

The Risk of Overcooling

It is possible to make a system run too cold. Hydraulic fluid that is below its ideal operating temperature range will have a higher viscosity. This can lead to sluggish actuator response, increased pressure drops, and even cavitation damage in the pump. Most systems target a stable operating temperature around 120-140°F (50-60°C).

Diagnostic Difficulty

Pinpointing the exact source of heat can be challenging. While an IR thermometer is a great starting point, definitively diagnosing a worn pump or internal valve leak may require specialized tools like a hydraulic flow meter to measure efficiency under pressure.

A Systematic Approach to Solving Overheating

Use this framework to guide your actions based on your specific situation.

- If your primary focus is routine maintenance: Start with the easiest and most common solutions—thoroughly clean the heat exchanger fins and verify the reservoir fluid level is correct.

- If your primary focus is diagnosing a specific overheating problem: Use an infrared thermometer to find abnormal hot spots on components, and check the system's pressure-relief valve settings.

- If your primary focus is long-term reliability and efficiency: Analyze the system for sources of wasted energy, such as a fixed-displacement pump constantly sending flow over a relief valve.

- If your primary focus is an immediate fix for an undersized cooling system: Adding or upgrading the heat exchanger is a direct and effective solution, provided you've ruled out major component failures.

By shifting your focus from treating the symptom to solving the cause, you can build a more reliable, efficient, and cost-effective hydraulic system.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Reduce Heat Generation | Check pressure settings, audit for internal leaks, optimize fluid viscosity. | Solves the root cause, improves efficiency, and lowers operating costs. |

| Improve Heat Dissipation | Service/clean existing coolers, verify reservoir conditions, upgrade cooling capacity. | Directly lowers fluid temperature for immediate relief. |

Is your hydraulic system running hot and wasting energy?

Overheating is a symptom of inefficiency that leads to costly downtime and high energy bills. KINTEK specializes in the lab equipment and consumables that keep your operations running smoothly. Our experts can help you diagnose the root cause of your hydraulic issues and recommend the right solutions for long-term reliability.

Contact us today to discuss how we can help you achieve a cooler, more efficient system. Get in touch via our contact form.

Visual Guide

Related Products

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Variable Speed Peristaltic Pump

- CVD Diamond for Thermal Management Applications

People Also Ask

- What product is made from press forging? Manufacturing Critical Components for Aerospace, Automotive, and Energy

- What function does a laboratory hydraulic press serve in nuclear fuel pellet formation? Precision Powder Compaction

- What role does a laboratory hydraulic press play in Fe-Cr-Al-Si alloy production? Mastering Powder Consolidation

- How do you calculate the capacity of a hydraulic press machine? Determine Tonnage with a Simple Formula

- Why must pressing equipment for metal nanopowders be equipped with vacuum or atmospheric protection? Prevent Oxidation

- Which safety device is used in power press machine? Essential Guards & Systems for Operator Protection

- What can a hydraulic press be used for? From Industrial Forging to Lab Analysis

- Are hydraulic presses dangerous? Understanding the Risks and Safety Measures for Your Lab