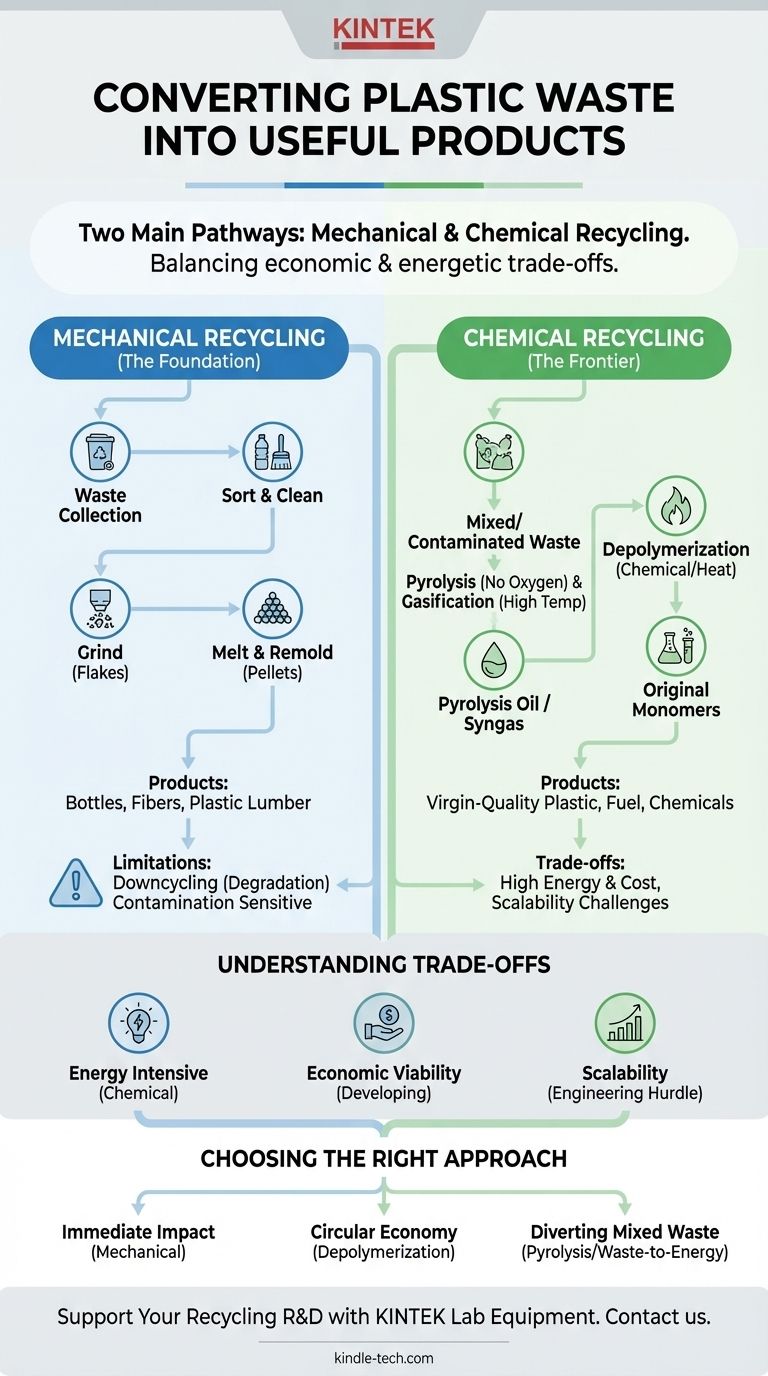

At its core, converting plastic waste into useful products follows two primary pathways: mechanical recycling, which re-melts and reforms the plastic, and chemical recycling, which breaks the plastic down into its fundamental chemical building blocks. While mechanical recycling is the most established method, chemical recycling offers a frontier for handling more complex waste and creating higher-quality materials.

The central challenge is not a lack of technical options, but the economic and energetic trade-offs inherent in each method. No single solution is a silver bullet; the optimal approach depends entirely on the type of plastic waste and the desired quality of the end product.

The Foundation: Mechanical Recycling

Mechanical recycling is the most common and intuitive form of recycling. It treats plastic as a thermoplastic material that can be melted and reshaped, preserving its basic polymer structure.

How It Works: The Grind-Melt-Remold Process

The process begins with collecting, sorting, and cleaning plastic waste. This sorting step is critical, as different plastic types (like PET, HDPE, and PP) cannot be mixed.

Once sorted, the plastic is shredded into small flakes, washed again to remove any remaining contaminants, and then melted down. This molten plastic is then extruded into pellets, which serve as the raw material for manufacturing new products.

The End Products: From Bottles to Benches

Mechanically recycled plastic is used in a wide range of applications. Clear PET from bottles can be turned back into new bottles or into polyester fibers for clothing and carpets. HDPE from milk jugs can become new jugs, pipes, or plastic lumber for park benches and decking.

The Critical Limitation: Downcycling and Contamination

The main drawback of mechanical recycling is downcycling. Each time plastic is melted and reprocessed, its polymer chains shorten, degrading its physical properties. This means a bottle might become a carpet fiber, but that fiber can rarely be turned back into a bottle.

Furthermore, the process is highly sensitive to contamination. Even small amounts of food residue, labels, or the wrong type of plastic can ruin an entire batch, making clean, well-sorted feedstock essential.

The Frontier: Chemical (Advanced) Recycling

Chemical recycling, often called advanced recycling, is a set of emerging technologies that break down the polymer's chemical structure. This allows it to handle mixed or contaminated plastics that are unsuitable for mechanical methods.

Breaking Down the Polymer: Pyrolysis and Gasification

Pyrolysis heats plastic waste in the absence of oxygen, causing it to decompose into a synthetic crude oil (pyrolysis oil), gas, and a solid residue called char. This oil can be refined and used to create new plastics or fuels.

Gasification uses even higher temperatures to convert plastics into a synthesis gas (syngas), primarily composed of hydrogen and carbon monoxide. Syngas is a basic chemical building block that can be used to produce fuels like methanol or other valuable industrial chemicals.

Restoring to Original Form: Depolymerization

For certain plastics like PET (used in drink bottles) and Polystyrene, depolymerization is a highly effective option. This process uses chemicals or heat to precisely break the polymer chains back down into their original monomers.

These monomers are identical to the "virgin" monomers used to make new plastic from petroleum. They can be purified and re-polymerized to create new, food-grade plastic of a quality equal to the original.

Understanding the Trade-offs

Choosing a conversion method is a complex decision involving significant trade-offs in energy, cost, and environmental impact.

The Energy Equation

Chemical recycling processes, particularly pyrolysis and gasification, are very energy-intensive. They require high temperatures and complex facilities, giving them a larger carbon footprint per unit of output compared to mechanical recycling.

Economic Viability

The economic case for chemical recycling is still developing. The high capital and operational costs, combined with fluctuating oil prices (which dictate the price of virgin plastic), make it difficult to compete. The purity of the final product is key; producing high-value monomers is often more viable than producing low-grade fuel.

The Scalability Challenge

While many chemical recycling technologies work well in a lab, scaling them to industrial levels that can process thousands of tons of waste is a major engineering and financial hurdle. Many facilities are still in the pilot or early commercial stage.

Choosing the Right Approach

Your strategy for converting plastic waste should be tailored to a specific goal, as there is no one-size-fits-all solution.

- If your primary focus is immediate impact with proven technology: Invest in improving sorting and collection infrastructure to create cleaner feedstock for mechanical recycling.

- If your primary focus is a true circular economy for "like-new" materials: Pursue depolymerization for specific, single-polymer waste streams like PET and support the development of pyrolysis to create feedstock for new plastics.

- If your primary focus is diverting mixed, low-quality plastic from landfills: Consider pyrolysis for fuel production or waste-to-energy as a final option, recognizing its environmental trade-offs.

The future of plastic waste management lies in intelligently combining these methods to create a resilient and truly circular system.

Summary Table:

| Method | Process | Key Products | Key Limitations |

|---|---|---|---|

| Mechanical Recycling | Grind, melt, remold | Pellets for bottles, fibers, plastic lumber | Downcycling, sensitive to contamination |

| Chemical Recycling | Pyrolysis, gasification, depolymerization | Pyrolysis oil, syngas, monomers for new plastics | High energy use, high cost, scalability challenges |

Ready to find the right plastic recycling solution for your lab or facility? KINTEK specializes in providing advanced laboratory equipment and consumables to support research and development in plastic recycling technologies. Whether you're exploring pyrolysis, depolymerization, or optimizing mechanical processes, our expertise and high-quality products can help you achieve more efficient and sustainable outcomes. Contact us today to discuss how we can support your recycling innovation goals!

Visual Guide

Related Products

- Powerful Plastic Crusher Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the disadvantages of roller mills? Key Limitations in Particle Size and Material Handling

- What is the difference between grinding and pulverizing? Achieve the Perfect Particle Size for Your Application

- How do you recycle rubber waste? Unlock the 3 Key Methods for Tire & Rubber Recycling

- How does a ball mill reduce particle size? Master Particle Size Reduction for Your Lab

- How does grinding process work? Master Particle Size Reduction for Superior Materials